In an article published in the journal Sensors, researchers have developed a fiber optic humidity sensor using a leakage mode that enables measurements at low humidity.

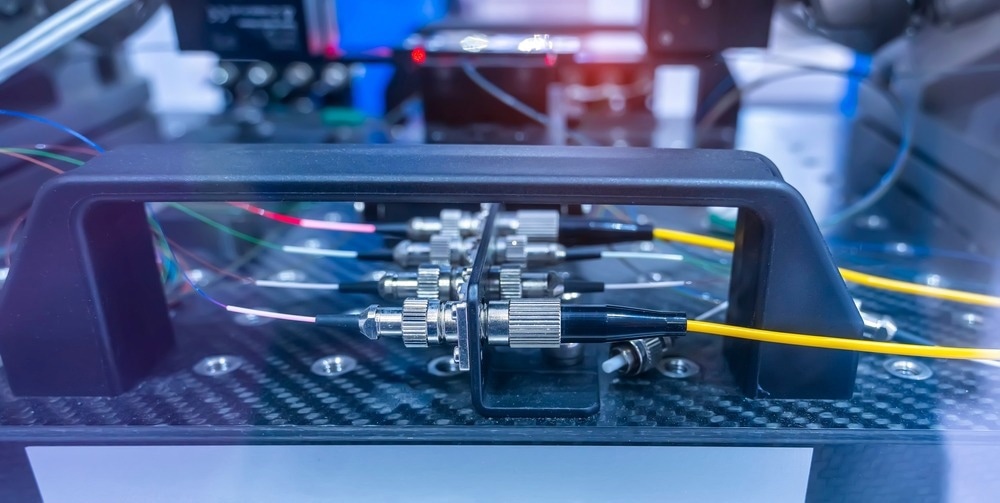

Study: Improving Measurement Range of a Swellable Polymer-Clad Plastic Fiber Optic Humidity Sensor by Dye Addition. Image Credit: asharkyu/Shutterstock.com

Numerous measuring techniques have been developed for humidity monitoring due to their applications in several industries, including food, medicine, and precision equipment manufacturing and storage. Because of their durability, broad detection range and superior repeatability, commonly used electrical sensors that employ capacitance or resistance are frequently utilized. Carbon-based materials, such as graphene oxide and carbon nanotubes, have recently been created as printing-based sensing materials and electric sensors.

Previous Developed Sensors and Their Drawbacks

Scientists have developed several humidity sensors in the past. For example, a composite thin film made of reduced graphene oxide and lignosulfonic acid was used to create a humidity sensor. Over an extensive range of relative humidities, from 22 percent to 97 percent, the sensor exhibited high responsiveness, minimal hysteresis, and steady repeatability. Researchers used printing technology to create a rapid and extremely sensitive ZrSe2-based humidity sensor with a linear relative humidity range of 15-80 percent RH, quick transient responses of one and two seconds, and high stability for 360 minutes.

But in severe settings, these electrical sensors confront several difficulties, including sensitivity to electromagnetic noise and the need for a power source close to the detecting device. Consequently, an optical fiber-based humidity sensor was suggested. The resistance to telemetry, explosion, corrosion, electromagnetism and other properties not present in electrical sensors make fiber-optic sensors the primary choice in a harsh environment.

Extension of a Previous Study

This study is the extension of a previous study conducted by the same researchers in which they developed a polyvinylpyrrolidone (PVP) cladding-based (a polymer that swells when exposed to moisture) light absorbing plastic optical fibers (POF) humidity sensor.

As a result, the researchers suggest a POF sensor in which a dye-doped coating is applied to a POF, with the form being adjusted by heating and stretching. Consequently, the change in the refractive index of the swellable polymer cladding in the leaking mode increases the change in transmitted light intensity.

In the previous study, the researchers have shown that dye doping permits measurements even in low humidity. This research expands on that study by investigating the effects of dye doping, sensor curvature, and variations in plastic optical fibers sensor sensitivity with sensing component length.

Working Principle of Sensor

In the presence of certain chemicals, some polymers show swelling characteristics. PVP is an example of a polymer that can selectively swell in water and lower its refractive index from 1.52 to 1.49; when water diffuses into PVP, the links between the polymer molecules enlarge, expanding the polymer's volume. The polymer's molecular density decreases, and its polarizability decreases due to this volume expansion.

Leakage Mode and Waveguide Mode

Brilliant Blue (BB), a dye intended to improve absorption, was added to the cladding, and polymethyl methacrylate was used to build the core. When the fiber behavior shifts from the leakage mode to the waveguide mode in the absence or presence of humidity, the intensity of the transmitted light considerably varies. Therefore, the blend polymer ratio was set so that the cladding polymer's refractive index in its unswollen condition was marginally more significant than the core polymer's.

At this wavelength, the leakage mode humidity range widens and the refractive index difference between the cladding and core increases.

Moreover, since sensors utilizing the leakage mode assess Fresnel reflection, the increased transmitted light intensity change increases the cladding-core refractive index difference. Therefore, this research proposes using the leakage mode for assessments at low humidity levels.

Significant Findings of the Study

The researchers created a sensor that uses the leakage mode to monitor humidity across a broad range, including low humidity.

To raise the angle of incidence at the core-cladding contact, the core form was straightened, and dye was included in the cladding to enhance the difference in refractive indices between the two materials and the cladding's absorbance.

Due to the higher variation in the transmitted light intensity in the leakage mode, measurements in low-humidity environments were possible.

The experimental findings supported linearizing the core geometry's ability to adjust the light intensity in the leaking mode. The dye's inclusion increased sensitivity and expanded the leaking mode area.

The experimental findings suggest that a sensor that can detect between 60 percent to 90 percent relative humidity may be enhanced to measure between zero percent to 95 percent relative humidity. The sensor's predicted reaction times for changes in humidity from 45 percent RH to zero and from zero to 45 percent RH was 22 seconds and 50 seconds, respectively.

Reference

Yuta Shimura, Yutaka Suzuki and Masayuki Morisawa (2022) Improving Measurement Range of a Swellable Polymer-Clad Plastic Fiber Optic Humidity Sensor by Dye Addition. Sensors. https://www.mdpi.com/1424-8220/22/16/6315/htm

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.