Staring through a microscope at samples of material for hours on end, attempting to locate monolayers, is one of the most laborious and intimidating tasks for undergraduate assistants in university research laboratories.

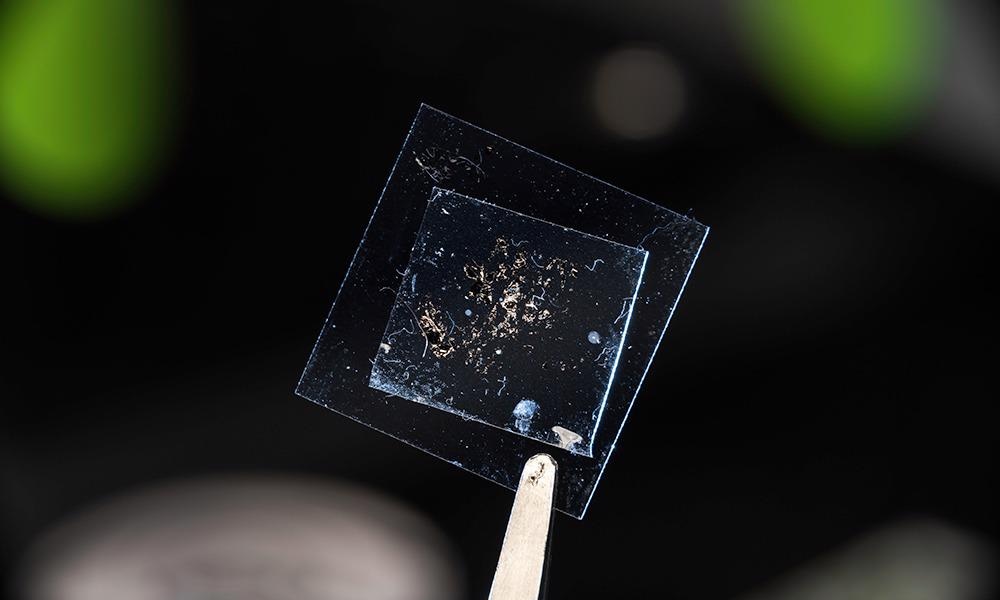

Researchers can process 100 images covering 1 cm × 1 cm sized samples like this one in around nine minutes using a new system that greatly simplifies the often tedious search for monolayers in the lab. Image Credit: University of Rochester photo/J. Adam Fenster.

Researchers can process 100 images covering 1 cm × 1 cm sized samples like this one in around nine minutes using a new system that greatly simplifies the often tedious search for monolayers in the lab. Image Credit: University of Rochester photo/J. Adam Fenster.

As a result of their unique properties, these two-dimensional materials — which are less than 1/100,000th the width of a human hair — are in high demand for use in photonics, electronics, and optoelectronic devices.

Research labs hire armies of undergraduates to do nothing but look for monolayers. It’s very tedious, and if you get tired, you might miss some of the monolayers or you might start making misidentifications.

Jaime Cardenas, Assistant Professor, Optics, University of Rochester

Even after all of that, the laboratories must double-check the materials using costly atomic force microscopy or Raman spectroscopy.

Jesús Sánchez Juárez, a Ph.D. student in the Cardenas Lab, has made work simpler for undergraduates, their research facilities, and companies that have difficulty identifying monolayers.

The unique technology is an automated scanning device that can sense monolayers with 99.9% accuracy, outperforming any other technique to date. The study was published in the journal Optical Materials Express.

At a fraction of the price. In far less time. With materials that are readily available.

One of the main objectives was to develop a system with a very small budget so that students and labs can replicate these methodologies without having to invest thousands and thousands of dollars just to buy the necessary equipment.

Jesús Sánchez Juárez, PhD Student and Study Lead Author, University of Rochester

For instance, the device he developed can be replicated using an inexpensive OEM (original equipment manufacturer) camera and a low-cost microscope with a 5× objective lens.

A Creative Adaptation of an AI Neural Network

We’re very excited. Jesús did several things here that are new and different, applying artificial intelligence in a novel way to solve a major problem in the use of 2D materials.

Jaime Cardenas, Assistant Professor, Optics, University of Rochester

By training an artificial intelligence (AI) neural network to scan for monolayers, numerous laboratories have tried to remove the need for expensive backup characterization tests that require human scanning. According to Cardenas, most laboratories that have attempted this approach plan to build a network from scratch, which takes a long time.

Rather, Sánchez Juárez began with AlexNet, a publicly available neural network that has already been trained to identify objects.

He then devised a novel method for inverting material images so that whatever was bright in the original image appears black and vice versa. Additional processing steps are applied to the inverted images.

At that juncture, the images “don’t look good at all to the human eye, but for a computer makes it easier to separate the monolayers from the substrates they are deposited on,” says Cardenas.

The bottom line: Sánchez Juárez’s system can process 100 images covering 1 cm × 1 cm sized samples in 9 minutes with near-perfect precision, compared to the long, laborious hours of scanning by undergraduates.

Sánchez Juárez adds, “Our demonstration paves the way for automated production of monolayer materials for use in research and industrial settings by greatly reducing the processing time.”

Applications include 2D materials suitable for photodetectors, lasers, excitonic light-emitting devices (LEDs), single photon emission, optical generation of spin–valley currents, and modulators.

Journal Reference:

Sánchez Juárez, J., et al. (2022) Automated system for the detection of 2D materials using digital image processing and deep learning. Optical Materials Express. doi.org/10.1364/OME.454314.