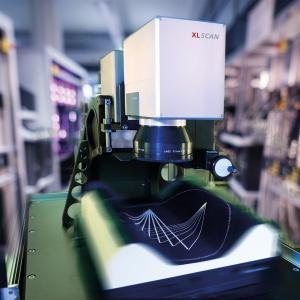

At the LASER World of PHOTONICS 2019 tradeshow in Munich, Germany, leading galvo-based scan solution provider SCANLAB GmbH is presenting its XL SCAN, for the first time with an additional axis.

XL SCAN integrates ultra-dynamic z axis into scan solution

XL SCAN integrates ultra-dynamic z axis into scan solution

Jointly developed with ACS Motion Control, this innovative scan system processes workpieces of practically unlimited size by combining a 2D scan head with an XY positioning stage. What’s new is the added ultra-dynamic z-shifter that enables highly precise surface processing of 3D-shaped workpieces in nearly any size.

Numerous laser processing applications are constrained by the scan system’s image field size. Large workpieces thus typically require stepwise processing of individual surface sections. But this approach produces relatively long process times and bears the risk of stitching errors. To eliminate those shortcomings, SCANLAB and ACS Motion Control designed the XL SCAN. This scan solution synchronizes one or multiple excelliSCAN scan heads and one or two mechanical XY stages, each with two servo axes. That turns the system into a highly dynamic scan solution for micromachining large workpieces at maximum accuracy.

An XL SCAN will be shown at the Munich tradeshow for the first time with an integrated excelliSHIFT z axis. Because this galvo-based z axis works completely without transmissive elements, it keeps up with the scan head’s fast dynamic performance and flexibly guides the laser spot. This will allow users to precisely process even 3D-shaped large-area workpieces. The user simply inputs the desired three-dimensional contour and can even let processing be simulated beforehand. Possible example applications include processing of windshields and surface structuring of mould tools. Initial test systems with integrated z axes will be deliverable starting in 2020.