Oct 25 2014

Molex Incorporated announced today that its first SlimRayTM Pre Wired LED Chip-On-Board (COB) Array Holders reduce assembly time while increasing reliability, with compression contacts that eliminate hand soldering and simplify the LED installation process.

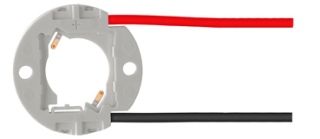

SlimRay Pre Wired LED Chip-On-Board (COB) Array Holders

SlimRay Pre Wired LED Chip-On-Board (COB) Array Holders

The holder for 13.35 by 13.35mm COBs comes as a single piece in a 25.0mm diameter, low 3.15mm profile height, rated at 300 volts DC and 3.0 amps. This design allows optics to be mounted closer to the light emitting surface (LES) and the gold plated compression contacts interface with array pads for stable power connections across a wide range of environments and conditions.

“Soldering wires directly to LED arrays is a time consuming process that can cause reliability concerns. Molex has designed a solderless, pre-wired system that provides lower heights and excellent wire-to-holder retention,” said Dave Rios, new product development manager, Molex.

Quality and reliability issues that arise from hand-soldering directly to LED arrays are resolved by means of SlimRay’s crimped, pre-stripped, and pre-installed color-coded power wires. The results are reduced installation time and improved overall process consistency and long-term reliability.

A robust housing design helps ensure stable long-term mechanical attachment even in high ambient temperatures. The integrated LED pre-hold tab secures the COB array prior to mounting the assembly to a heat sink for final assembly, minimizing installation time. The stripped wire ends can be easily terminated according to customer preference.

“For lighting manufacturers using LED COB arrays, the Molex SlimRay pre-wired LED COB holder enables quick, easy and reliable installation in all types of fixture applications,” adds Rios.