This article overviews femtosecond lasers and their use in precision photonics manufacturing.

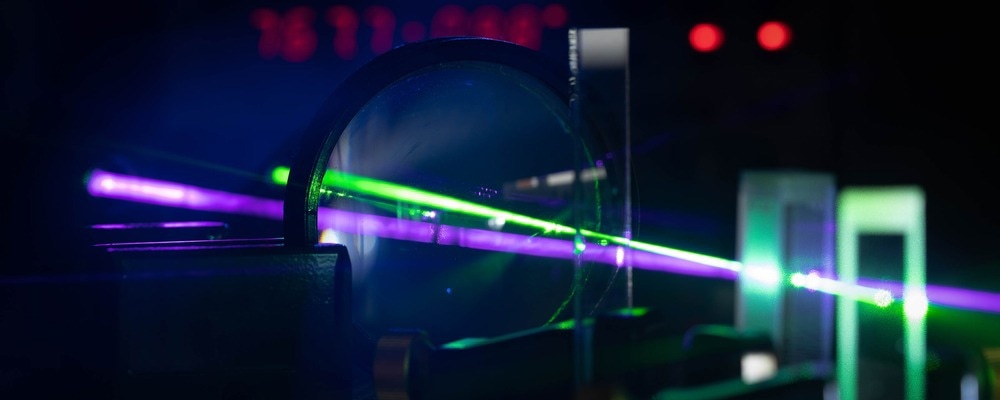

Image Credit: luchschenF/ShutterStock.com

Why Are Femtosecond Lasers Used in Precision Photonic Manufacturing?

A femtosecond laser emits ultra-short optical pulses with durations below one picosecond, reaching the femtosecond domain (1 fs = 10-15 s). Femtosecond lasers are characterized by their extremely short pulse widths and high peak intensities.

The ultra-short bursts minimize residual heating, ensuring precise material processing with minimal collateral damage. Their high peak intensities induce nonlinear optical interactions like multiphoton ionization and plasma formation, providing precise spatial control over laser energy for various applications.

The nonlinear confinement effect of femtosecond lasers allows for nanoscale resolution, achieving features smaller than the diffraction limit of light. These lasers are highly versatile, as they can work with various materials, including metals, semiconductors, ceramics, polymers, and composites, without needing masks or photoresists. Their ability to focus within transparent materials also facilitates the creation of intricate three-dimensional (3D) structures, essential for fabricating integrated photonic chips.

Overall, femtosecond lasers are ideal for precision micromachining and photonics manufacturing.

Applications in Precision Photonic Manufacturing

Lithography of Photonic Crystals

Precise nanometer-scale control of unit structures and gaps is crucial to control light effectively in photonic crystals within the near-infrared and visible light range. Femtosecond lasers excel in manufacturing these structures by directly fabricating 3D micro-nano structures in transparent materials, leveraging their ultra-short pulse duration for exceptional precision.

This was demonstrated in a study published in Light: Science & Applications, which introduced a method for fabricating photonic crystal structures using nanoscale femtosecond laser multi-beam lithography. The researchers focused a controllable multi-beam light field inside a crystal and combined it with chemical etching. This approach allows for precise control of sub-wavelength-sized structural units and gaps, overcoming limitations of single-beam processing.

The proposed method is cost-effective and simple, enabling 3D photonic crystal structures inside crystals, with potential applications in optical communication and light manipulation.

Streamlining Periodic Nanostructure Fabrication

The progress in material science and nanofabrication has led to the exploration of periodically nanostructured surfaces, such as plasmonic and dielectric metasurfaces, for advanced photonics applications. Conventionally, lithographic methods are employed to process these periodic surface structures (PSSs), which can be complex and time-consuming.

However, focused femtosecond lasers provide a one-step, mask-free, and efficient alternative applicable to various materials. This allows the creation of features smaller than the laser wavelength through laser-induced PSSs (LIPSSs).

Recent studies, particularly those investigating wide-bandgap transparent crystals like LiNbO3, showcase the potential of femtosecond lasers in fabricating large-area LIPSS with enhanced optical absorption through controlled heating strategies. This offers a promising avenue for precision manufacturing in dielectric crystals beyond LiNbO3.

Designing 3D Photonic Integrated Structures

Femtosecond laser direct writing offers significant potential for fabricating 3D photonic integrated circuits (PICs) in transparent substrates. However, a key challenge in this technology is achieving smooth and large refractive index changes within laser-irradiated regions, hindering the development of compact PICs.

A study published in Science China Physics, Mechanics & Astronomy addressed this issue, proposing a method to significantly suppress bend loss in waveguides with small radii of curvature, thereby paving the way for downsizing 3D photonic integrated circuits.

The proposed approach involves inscribing multiple modification tracks in fused silica using femtosecond laser direct writing, resulting in enhanced refractive index contrast and successful reduction of bend loss in curved waveguides. This breakthrough holds promise for advancing the integration density and flexibility of 3D photonic devices.

3D Micro- and Nano-structuring in Dielectric Materials

Femtosecond laser irradiation followed by chemical etching (FLICE) leverages laser-induced changes in chemical properties to selectively etch laser-modified regions. This enables complex 3D micro- and nanostructures to be directly written inside dielectric materials. FLICE has been applied to create embedded hollow microstructures for microfluidics and 3D optofluidics in glasses.

Recent work has achieved ultra-high etching selectivity of over 100,000 in crystals like YAG and sapphire. This has enabled 3D photonic lattices, waveguides, and nanopores at the nanoscale without fracturing the crystal.

Surface Lithography

As a mask-less, high-precision 3D machining technique, femtosecond laser processing can perform surface lithography on materials like thin-film lithium niobate. This breakthrough has successfully overcome challenges in material integration and enabled the fabrication of high-performance photonic components.

For example, researchers have used femtosecond laser-assisted chemo-mechanical polish lithography (CMPL) to create low-loss waveguides and high-Q micro-resonators on lithium niobate chips. This processing strategy has strong potential to functionalize different crystal platforms for integrated photonics.

High-Speed, High-Quality Silicon Ablation

Silicon ablation with femtosecond lasers involves using bursts of ultrashort pulses to precisely remove material from a silicon substrate. This process is crucial in precision photonics for creating intricate structures with minimal thermal damage, enabling the fabrication of high-quality optical devices like optical waveguides.

Researchers at the RIKEN Center for Advanced Photonics have developed a novel technique called BiBurst mode, which uses GHz bursts of femtosecond laser pulses grouped in MHz envelopes for efficient and high-quality silicon ablation. The results of these investigations are published in the International Journal of Extreme Manufacturing.

The team demonstrated that utilizing the BiBurst mode enables silicon ablation at a rate 4.5 times faster than the single-pulse mode, with superior quality. The mechanism involved the absorption of subsequent pulses at absorption sites generated by preceding pulses, contributing to increased efficiency. This breakthrough could significantly impact fundamental research and industrial applications in femtosecond laser processing, offering improved throughput and microfabrication precision.

Manufacturing Quantum Photonic Processors

Femtosecond laser writing (FLW) stands out for its low cost, simplicity, and rapid prototyping capabilities for passive and reconfigurable integrated photonic circuits. The technology's quick reconfigurability makes it valuable for initial-stage assessments in optical labs.

A study published in Applied Physics Letters employed FLW technology to fabricate a programmable two-qubit quantum photonic processor. The fabricated FLW quantum processor achieved high fidelity, with single-qubit gates at 99.3 % and a two-qubit CNOT gate at 94.4 %.

Despite challenges such as propagation loss and low refractive index contrast, FLW chips exhibited naturally low-loss coupling with standard single-mode fibers, providing an advantage in quantum photonic experiments.

Conclusion

Femtosecond laser processing is rapidly emerging as a crucial technique in advancing photonics manufacturing, unlocking new possibilities in design and architecture. Ongoing developments suggest that its influence in industry and academia will continue to expand in the coming years.

More from AZoOptics: Pushing the Limits of Femtosecond Lasers

References and Further Reading

Skryabin, N. N., Kondratyev, I. V., Dyakonov, I. V., Borzenkova, O. V., Kulik, S. P., Straupe, S. S. (2023). Two-qubit quantum photonic processor manufactured by femtosecond laser writing. Applied Physics Letters. doi.org/10.1063/5.0137728

Jia, Y., Chen, F. (2023). Recent progress on femtosecond laser micro-/nano-fabrication of functional photonic structures in dielectric crystals: A brief review and perspective. APL Photonics. doi.org/10.1063/5.0160067

Li, J., Yan, J., Jiang, L., Yu, J., Guo, H., Qu, L. (2023). Nanoscale multi-beam lithography of photonic crystals with ultrafast laser. Light: Science & Applications. doi.org/10.1038/s41377-023-01178-3

Liu, Z., Liao, Y., Fang, Z., Chu, W., Cheng, Y. (2018). Suppression of bend loss in writing of three-dimensional optical waveguides with femtosecond laser pulses. Sci. China Phys. Mech. Astron. doi.org/10.1007/s11433-018-9202-0

Caballero-Lucas, F., Obata, K., Sugioka, K. (2022). Enhanced ablation efficiency for silicon by femtosecond laser microprocessing with GHz bursts in MHz bursts (BiBurst). International Journal of Extreme Manufacturing. doi.org/10.1088/2631-7990/ac466e

Gao, R., Zhang, H., Bo, F., Fang, W., Hao, Z., Yao, N., ... & Cheng, Y. (2021). Broadband highly efficient nonlinear optical processes in on-chip integrated lithium niobate microdisk resonators of Q-factor above 108. New Journal of Physics. doi.org/10.1088/1367-2630/ac3d52

Wu, R., et al. (2018). Long low-loss-litium niobate on insulator waveguides with sub-nanometer surface roughness. Nanomaterials. doi.org/10.3390/nano8110910

Ródenas, A., Gu, M., Corrielli, G., Paiè, P., John, S., Kar, A. K., Osellame, R. (2019). Three-dimensional femtosecond laser nanolithography of crystals. Nature Photonics. doi.org/10.1038/s41566-018-0327-9

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.