X-ray photoelectron spectroscopy (XPS) has become an indispensable characterization technique for analyzing the surface chemistry of thin films and coatings. With its ability to probe just the top few nanometers and reveal elemental composition, chemical bonding, and electronic structure, XPS provides unparalleled insights into how surface and interface properties determine film performance. This article will discuss XPS's principles, applications, challenges, and future outlook in thin film analysis.

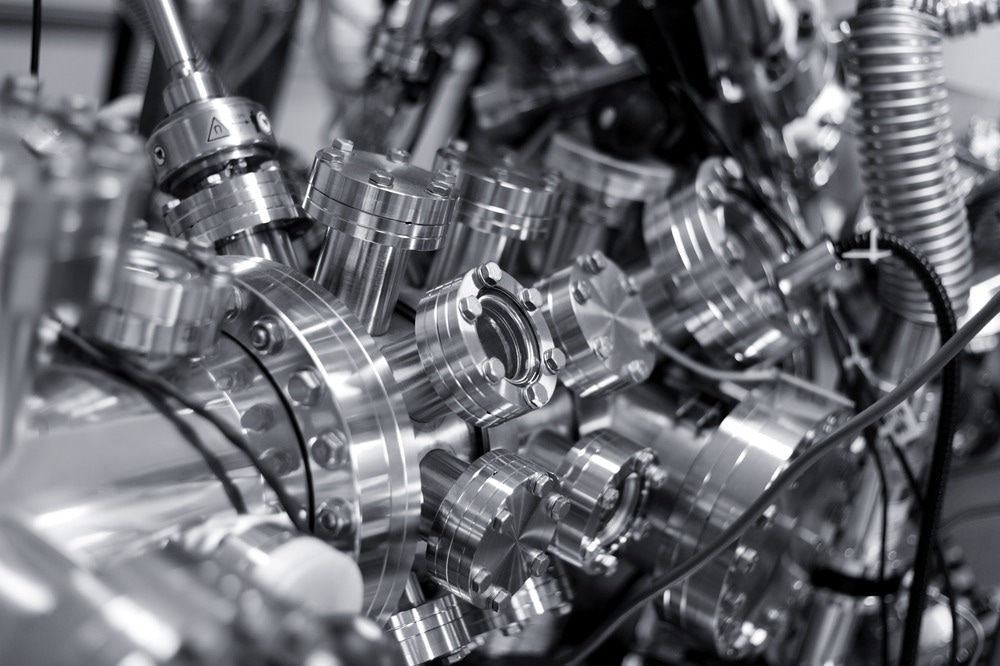

Image Credit: Alexander Gatsenko/Shutterstock.com

What is X-Ray Photoelectron Spectroscopy?

X-ray photoelectron spectroscopy (XPS) is a non-destructive, surface-sensitive quantitative spectroscopic technique used to analyze engineered and natural materials' outermost layers (~10 nm or '30 atomic layers).

It helps to identify the composition of material surfaces, determine the relative ratios of surface components, and reveal the chemical state of ions by measuring the binding energies of elements, which reflect their bonding characteristics.

The Significance of XPS in Analyzing Thin Films and Coatings

Thin films and coatings significantly enhance diverse material properties, such as corrosion resistance and optical performance; therefore, understanding their surface chemistry and composition is vital for tailoring their attributes to specific applications.

Thin film's properties are influenced by deposition conditions, gas reactivity, substrate composition, and temperature, and changes in these parameters can lead to varied outcomes. However, analyzing such films is challenging due to minimal sample availability, typically a few milligrams.

Over the years, XPS has developed the leading surface analysis technique due to its unique blend of surface sensitivity, quantitative elemental data, and chemical state information, offering a comprehensive approach to characterize thin films and coatings and understand their behavior.

X-Ray Photoelectron Spectroscopy: How Does It Analyze Thin Films and Coatings?

X-ray photoelectron spectroscopy (XPS) relies on the photoelectric effect to analyze a material's surface's elemental composition and chemical state.

In XPS, the sample surface is irradiated with X-rays of known energy, which interact with atoms in the sample, ejecting core electrons whose kinetic energy is measured by a detector.

According to the photoelectric effect equation:

Ekinetic = Ephoton - Ebinding – φ

Ephoton is the energy of the incident X-ray photons, Ebinding is the binding energy of the photoelectron, and φ is the spectrometer work function.

Since Ephoton and φ are known, measuring Ekinetic allows the determination of Ebinding, and the Ebinding values provide a fingerprint of the elements present and their chemical states, revealing the sample composition and bonding information.

Additionally, electron binding energies provide quantitative information about the material's surface's elemental composition, chemical state, and electronic structure, making XPS invaluable for analyzing the top few nanometers of thin films, where properties often diverge from the bulk.

Applications: Thin Film and Coating Analysis

Elemental Composition Analysis

One major application of XPS is determining the elemental composition of thin films and coatings, including detecting trace impurities that may impact performance and longevity.

XPS can identify all elements except hydrogen and helium by measuring the binding energies of emitted photoelectrons, providing a quantitative surface composition analysis.

Chemical State Identification

XPS can assess the chemical state of surface elements by observing changes in binding energy (peak shifts) and oxidation states resulting from alterations in chemical interactions with neighboring elements. For instance, in the polyethylene terephthalate (PET) analysis, the shifts in peaks from carbon and oxygen atoms with different binding states reveal the material's chemical structure and ratios of bindings.

This analytical approach can be extended to investigate changes in binding after surface treatments and to determine the valence of metallic elements in transparent conductive films like indium tin oxide (ITO).

Depth Profiling

XPS can profile the composition and structure of thin films and coatings as a function of depth. This depth profiling capability is critical for understanding how composition varies throughout a material's thickness and layer structure. For example, it can detect interdiffusion between film layers or oxidation that has penetrated deeper than just the surface.

It is usually performed by sequentially sputtering away thin layers of the sample's surface using an ion beam while analyzing the XPS spectra after each sputtering cycle.

Imaging of Chemical Thin Film Species

XPS can be used for elemental imaging of thin films and coatings, providing spatial maps of surface chemistry and elemental distribution.

It complements Auger microscopy, a common surface elemental composition imaging technique, albeit with the potential for electron beam damage, particularly in insulating samples. In addition, high-resolution XPS imaging (with spatial resolution up to 10 nm) enables versatile composition analysis, showcasing its capability in studying thin films and coatings.

Challenges and Future Outlooks

X-ray photoelectron spectroscopy (XPS) is a powerful surface analysis technique for thin films, but certain constraints limit its effectiveness.

XPS only examines the outermost ~10 nm of material, rendering it less suitable for investigating bulk-related properties and three-dimensional elemental compositions. In addition, operating in ultrahigh vacuum conditions (< 10-9 Torr), XPS can pose challenges with volatile samples, and its X-ray beams lack the precision of electron beams, leading to larger analyzed areas that might not effectively detect small defects.

Efforts are underway to overcome these limitations through advancements in spatial resolution, depth profiling, in situ capabilities, charge compensation, and integration with complementary techniques. Focused X-ray beams are poised to enable micron or nano-scale mapping, enhanced depth profiling will venture into subsurface layers, and in situ measurements will unveil real-time surface reactions. Charge mitigation systems will facilitate the analysis of insulating films, while combined workflows with other techniques will provide comprehensive insights.

XPS's versatility will continue to play a pivotal role in exploring film chemistry, composition, interfaces, and electronic structure, thereby advancing our understanding of structure-property relationships in thin films and coatings.

More from AZoOptics: The Role of Photonic Crystals in Controlling Light Propagation

References and Further Reading

Bluhm, H. (2011). X-ray photoelectron spectroscopy (XPS) for in situ characterization of thin film growth. In In situ characterization of thin film growth (pp. 75-98). Woodhead Publishing. https://doi.org/10.1533/9780857094957.2.75

Geng, S., Zhang, S., & Onishi, H. (2002). XPS applications in thin films research. Materials Technology, 17(4), 234-240. https://doi.org/10.1080/10667857.2002.11752992

Good, C., & Facey, H. (2019). X-ray Photoelectron Spectroscopy (XPS). [Online]. Available at: https://chem.libretexts.org/Courses/Franklin_and_Marshall_College/Introduction_to_Materials_Characterization__CHM_412_Collaborative_Text/Spectroscopy/X-ray_Photoelectron_Spectroscopy_(XPS)

Hartmann, A. J., & Lamb, R. N. (1997). X-ray photoemission spectroscopy of thin films. Current Opinion in Solid State and Materials Science, 2(5), 511-516. https://doi.org/10.1016/S1359-0286(97)80038-1

Levasseur, A., Vinatier, P., & Gonbeau, D. (1999). X-ray photoelectron spectroscopy: A powerful tool for a better characterization of thin film materials. Bulletin of Materials Science, 22, 607-614. https://doi.org/10.1007/BF02749975

Mogk, D. (2023). X-Ray Photoelectron Spectroscopy (XPS; aka Electron Spectroscopy for Chemical Analysis, ESCA). [Online]. Montana State University. Available at: https://serc.carleton.edu/msu_nanotech/methods/xps.html

Stevie, F. A., & Donley, C. L. (2020). Introduction to x-ray photoelectron spectroscopy. Journal of Vacuum Science & Technology A, 38(6). https://doi.org/10.1116/6.000041

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.