Lasers are increasingly playing a crucial role in different fields, such as entertainment, computing, medicine, instrumentation, telecommunications, and manufacturing, specifically additive manufacturing. This article discusses the application of lasers in additive manufacturing/three-dimensional (3D) printing methods.

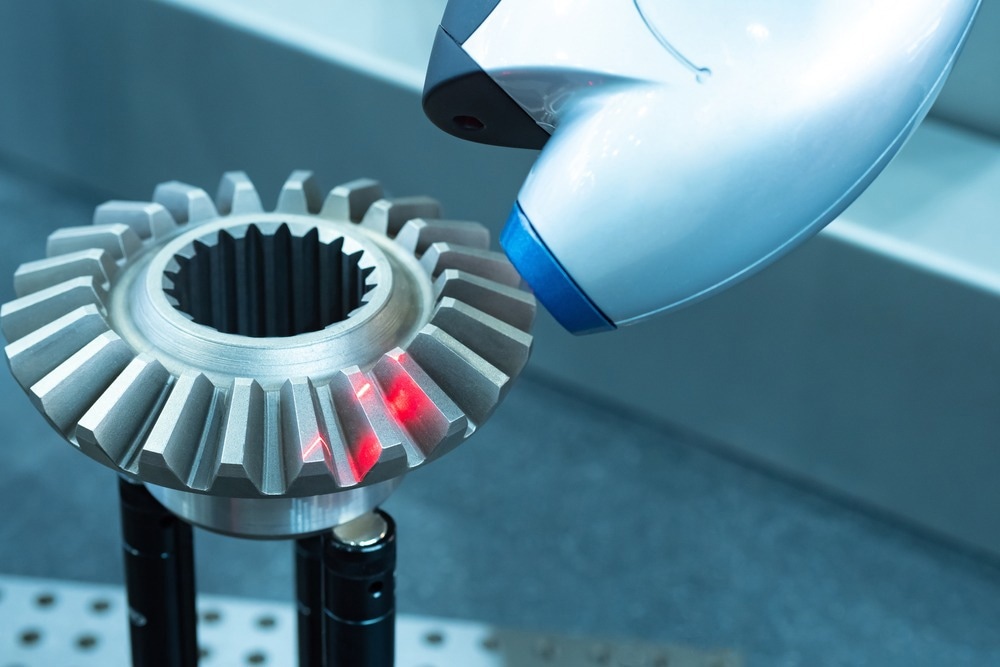

Image Credit: FOTOGRIN/Shutterstock.com

Importance of 3D Printing Lasers

In additive manufacturing/3D printing, lasers are primarily used in directed energy deposition, powder bed fusion, and vat photopolymerization methods to improve product quality, reduce manufacturing costs, and increase productivity.

In directed energy deposition, 3D printing lasers are used in multiple-layer laser cladding, laser-engineered net shaping (LENS), direct laser deposition, and direct metal deposition (DMD) processes, while in the vat polymerization method, lasers are utilized in stereolithography (SLA).

3D printing lasers are used for selective laser sintering (SLS) and selective laser melting (SLM) in the powder bed fusion method. Existing commercial additive manufacturing systems use several laser technologies, with powers between one W to six kW and wavelengths between ultraviolet/354.7 nm and infrared/10.6 µm.

However, the 3D printing laser requirements can vary depending on the additive manufacturing process. For instance, lasers used in SLA must be matched with the polymer absorption spectrum, while shorter wavelength diode laser is used for the DMD process.

Key Laser Additive Manufacturing Techniques

In the SLS technique, high-powered carbon dioxide lasers are utilized as 3D printing lasers to bind/fuse finely powdered materials, primarily polymers such as polyamides in powder form, into solid objects.

A printer applies a uniform powder layer before sintering the layer carefully. The procedure is repeated several times until the desired item is manufactured with high accuracy. The SLS process can produce 3D parts quickly, which makes the process economically attractive for commercial enterprises.

A high-energy ultraviolet laser is used in SLA to harden/solidify photo-reactive resins, such as low molecular weight epoxy macromers and polyacrylate, in a layered manner with fine details to manufacture a desired 3D structure. The size of the smallest details in SLA is between 50 µm-200 µm.

SLA possesses several advantages, including a smooth surface finish and superior dimensional accuracy. Thus, the technique is used to create nonstructural parts and prototypes with good surface finish and dimensional control.

SLM employs fiber lasers to create 3D structures by melting a series of fine metal powder layers selectively. Initially, the powder material heats up and melts when exposed to radiation and forms a liquid pool.

Then, the final structure is obtained after the cooling and solidification of the molten liquid pool. SLM can produce lightweight structures and complex geometries, making it an adaptable additive manufacturing method based on 3D printing lasers.

In all three processes, the laser beam is steered at high speed to target locations by the laser beam scanner on the 3D model-defined build plane. The software and scan controller is used to convert the entire 3D model job into a series of laser and motion control commands to synchronize the laser firing and laser beam scanning motion.

Layer thickness is one of the crucial process factors in additive manufacturing. A part can be post-processed/directly manufactured to a near-precise shape by decreasing the layer thickness using SLA and SLM. However, the use of these techniques can reduce the production speed.

Currently, 20-100 µm and 130-380 µm layer thicknesses can be realized using SLM/SLS and commercial DMD equipment, respectively. The use of more powerful 3D printing lasers, with improved process control and better wall plug efficiency, can address several existing drawbacks of the additive manufacturing process, including high energy consumption, part reproducibility and process repeatability, and layer thickness/deposition rate.

Application of Laser Additive Manufacturing

Additive manufacturing methods involving 3D printing lasers are used in several industries, including electronics, medical, automotive, and aerospace. The SLM process has been significantly beneficial for the aerospace, automotive, and medical industries as it can effectively create lightweight structures.

In aerospace and automotive, the rising demand for lightweight structures is increasing the application of DMD, SLM, and SLS techniques. Laser additive manufacturing methods are used for aerospace component fabrication and repair and for laser sintering of ceramic materials used in astronautical and aeronautical applications.

Laser additive manufacturing methods, such as SLM, SLA, and SLS, are used to realize minimally invasive surgery and replicate anatomic structures in the healthcare sector. For instance, SLA is used to manufacture 3D prototype parts and implant structures. Customized prosthetics have also been manufactured using these methods for biomedical applications.

Micro-SLS and SLA are used in the electronics sector to achieve accelerated product development and miniaturization and develop smart microsystems. Prototyping components created using the SLS technique are used extensively in the design of electrical, electronic, combat, and transport systems.

More from AZoOptics: What Is Laser Diffraction and How Is It Used to Measure Particle Size Distributions?

References and Further Reading

Pinkerton, A. J. (2016). [INVITED] Lasers in additive manufacturing. Optics & Laser Technology, 78, 25-32. https://doi.org/10.1016/j.optlastec.2015.09.025

Schmidt, M., Merklein, M., Bourell, D., Dimitrov, D., Hausotte, T., Wegener, K., Overmeyer, L., Vollertsen, F., Levy, G. N. (2017). Laser based additive manufacturing in industry and academia. CIRP Annals, 66(2), 561-583. https://doi.org/10.1016/j.cirp.2017.05.011

Brandt, M. (2016). Laser Additive Manufacturing- Materials, Design, Technologies and Applications. https://www.researchgate.net/publication/310831774_Laser_Additive_Manufacturing-_Materials_Design_Technologies_and_Applications

How Laser Additive Manufacturing is Revolutionizing Industrial Production [Online] Available at https://novantaphotonics.com/how-laser-additive-manufacturing-is-revolutionizing-industrial-production/#:~:text=This%20is%20done%20by%20adding,a%20new%20freedom%20in%20design. (Accessed on 05 August 2023)

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.