Modern microscopic methods such as atomic force microscopy (AFM) have significantly increased our understanding of bitumen microstructure. This article will discuss this topic further, looking at applications and the industry’s future.

Bitumen material. Image Credit: hans.slegers/Shutterstock.com

What is Bitumen?

Bitumen is a material created by distilling crude oil. It is frequently used in construction, particularly for roads, motorways, and pavements.

Bitumen materials exhibit remarkable water resistance and adhesive characteristics. The distillation process separates the heavier bitumen from the lighter components of crude oil, such as gasoline and diesel.

Natural bitumen deposits can also be found at the bottom of ancient lakes, where rotting, heat and compressed prehistoric species formerly existed.

Bitumen contains calcium, iron, sulfur, oxygen, and complex hydrocarbons. The type and source of crude oil used determines the material's quality and simplicity of manufacture.

Under significant weights, bitumen can permanently distort, and cracking may occur if the material is continually under stress. They might also become brittle as a result of oxidation.

The composition of the bitumen mixture and the temperature impact its shape. Understanding the structure and dynamics of bitumen is essential to using them efficiently.

Test Methods for Bitumen

Several cutting-edge test methods in material science have been applied to bitumen to improve our understanding of its features.

Several microscopy methods help examine the morphological properties of bitumen materials. A non-exhaustive list includes:

- Fluorescence microscopy

- Scanning electron microscopy

- Polarized light microscopy

Due to technical limitations, it is still challenging to observe important bitumen properties at the nanoscale using the aforementioned techniques.

The development of atomic force microscopy (AFM) offers a powerful tool to overcome these technical limitations. AFM is a quick surface imaging technology that enables the observation and study of materials' 2D and 3D topography with nanoscale resolution.

What are Atomic Force Microscopes?

Microscopes have advanced rapidly in conjunction with technological advancement throughout the history of instrumentation, pushing scientific study and material creation to higher levels of detail.

Scanning tunneling microscopy (STM), a valuable method for observing the surface properties of materials, was created by Binning and Rohrer in 1981. However, the need for STM samples to be electrically conductive restricts applications.

The first AFM apparatus was created by Binning et al.. The forces between the probe and specimen are exploited in this sophisticated surface imaging technology, built on STM's foundation, to investigate the properties of material surfaces at the nanoscale.

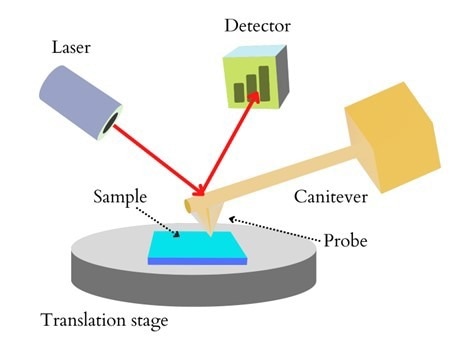

Figure 1: Schematic diagram of an AFM. Image Credit: Ilamaran Sivarajah

A probe, laser, cantilever, an electrically driven scanner, and photo-detector are often included in a conventional AFM (see figure 1).

The piezoelectric ceramic tube (PZT) governs the probe's movement in the x, y, and z directions during scanning. The sample's surface undulation causes a shift in the tip's position relative to the sample as it is scanned in the x and y directions.

The difference in laser intensity is detected by the detector, which is proportional to the deformation of the cantilever after the laser beam is aimed at the rear of the cantilever and reflected to the photodetector.

To produce surface topography and phase maps, the feedback mechanism continuously modifies the distance between the tip and the sample based on differences between detector signals.

AFM Scanning Methods

Three operating modes for the standard AFM are available: contact, tapping, and non-contact modes. Because they are sensitive to outside variables, bitumen is rarely used in touch or non-contact modes. In contrast, the tapping mode involves the tip intermittently tapping the sample surface for imaging.

In scanning, the cantilever oscillates at an amplitude close to the resonance frequency, allowing the tip to periodically touch the sample. When the tip of the cantilever is not in contact with a surface, it vibrates with relatively significant amplitude. However, when the tip retracts from the surface, the amplitude diminishes.

Variations of AFM for Bitumen Analysis

Variations to the AFM have been continuously developed to tackle different applications. The innovations have addressed many aspects of AFM, including detector mechanisms, probe materials, sample preparation, and loading methods. Some AFM innovations have been regarded as a better match for bitumen analysis.

A scientific team led by Dr. Alexandre Dazzi produced AFM-IR. This hybrid technology cleverly combines the ability of AFM to observe objects at the nanoscale with the ability of infrared spectroscopy to analyze things such as chemical composition. It can take snapshots of broad-band point spectra and narrowband functional group distribution maps of samples at the nanoscale.

This cutting-edge technology uses photothermally induced resonance to boost infrared spectra's spatial resolution past the optical diffraction limit.

Peak force tapping mode, a unique AFM-based imaging technique, was announced by Bruker in 2011. The scanning tube's movement maintains a consistent peak force between the probe and sample, which reflects the surface topography maps. Due to its modest imaging force compared to other operation methods, the peak force tapping mode is best for soft and sticky materials.

AFM maps' quality is directly correlated with the caliber of sample preparation. Notably, the surface of the prepared sample must be adequately smooth. Choosing the right AFM probe is crucial to producing high-quality maps.

Application of AFM for Bitumen

The research on bitumen has extensively utilized sophisticated AFM technology in determining critical characteristics. In-depth information obtained from AFM images of bitumen includes:

- Moisture damage and Adhesion between bitumen and aggregates

- Interfaces between bitumen and mineral aggregates

- Bitumen structure modified by Styrene-Butadiene-Styrene (SBS)

- Bitumen structure modified by crumb rubber

- Warm-mix bitumen

- Bitumen aging

- Recovery of aged bitumen properties

- Blending between new and aged bitumen

- Damage and self-healing mechanisms of bitumen

The Future of Using Atomic Force Microscopy for Bitumen Materials

AFM offers a cutting-edge scientific tool to evaluate bitumen's morphological, mechanical, and chemical properties at the nanoscale.

This technique helps researchers learn more about macroscopic property mechanisms such as bitumen aging, water damage, and other properties described above.

While newer test methods to explore phase dynamics will improve the insights into bitumen, AFM has provided a substantial wealth of information on the make-up and structure of bitumen.

References and Further Reading

M. Zhang, P. Hao, S. Dong, Y. Li, G. Yuan. (2020) Asphalt binder micro-characterization and testing approaches: A review. Measurement. 151, 107255, https://doi.org/10.1016/j.measurement.2019.107255

Chengwei Xing, Wei Jiang, Mingchen Li, Ming Wang, Jingjing Xiao, Zhoucong Xu. (2022) Application of atomic force microscopy in bitumen materials at the nanoscale: A review. Construction and Building Materials, Volume 342, Part B, 128059, ISSN 0950-0618, https://doi.org/10.1016/j.conbuildmat.2022.128059.

Sivarajah, I. (2021) Atomic Force Microscopy: General Principles and Applications. [Online] AZoOptics.com. Available at: https://www.azooptics.com/Article.aspx?ArticleID=2083

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.