AZoOptics speaks to researcher Prabodhi Nanayakkara from the University of Surrey about her work involving the key design rules of curved X-ray detectors. Nanayakkara hopes the study's findings will make way for clearer and safer X-rays and radiation therapy.

How did you begin your research into X-ray detectors?

I am a Materials Science and Engineering graduate from the University of Moratuwa, Sri Lanka. My mother is a nurse in Sri Lanka. As a result, I was exposed to an environment that instilled the importance of proper medical care from a very early age. When I was looking for Ph.D. opportunities abroad, I came across the work on a new X-ray detector technology that was being developed at the Advanced Technology Institute at the University of Surrey by Dr. Hashini Thirimanne as part of her Ph.D. and supervized by Professor Ravi Silva, who is a world-renowned nanotechnologist. I was fascinated by this new technology and believed that this was the ideal opportunity for me to contribute to the betterment of humanity. It fitted with my background in Materials Science and Engineering, especially in developing tailored nanomaterials, and my desire to contribute to new medical technologies. I am now developing this novel hybrid X-ray detector technology further.

What has your team identified as the key design rules for making curved X-ray detectors?

To function as a curved detector, we realized that it must possess not only excellent detector response characteristics but also high levels of mechanical flexibility/bendability characteristics. But this is only possible by optimizing the microscopic and macroscopic properties of the film. For our detectors, we use a mixture of carbon-based electronic materials (semiconducting polymers and small molecules) as well as nanoparticles.

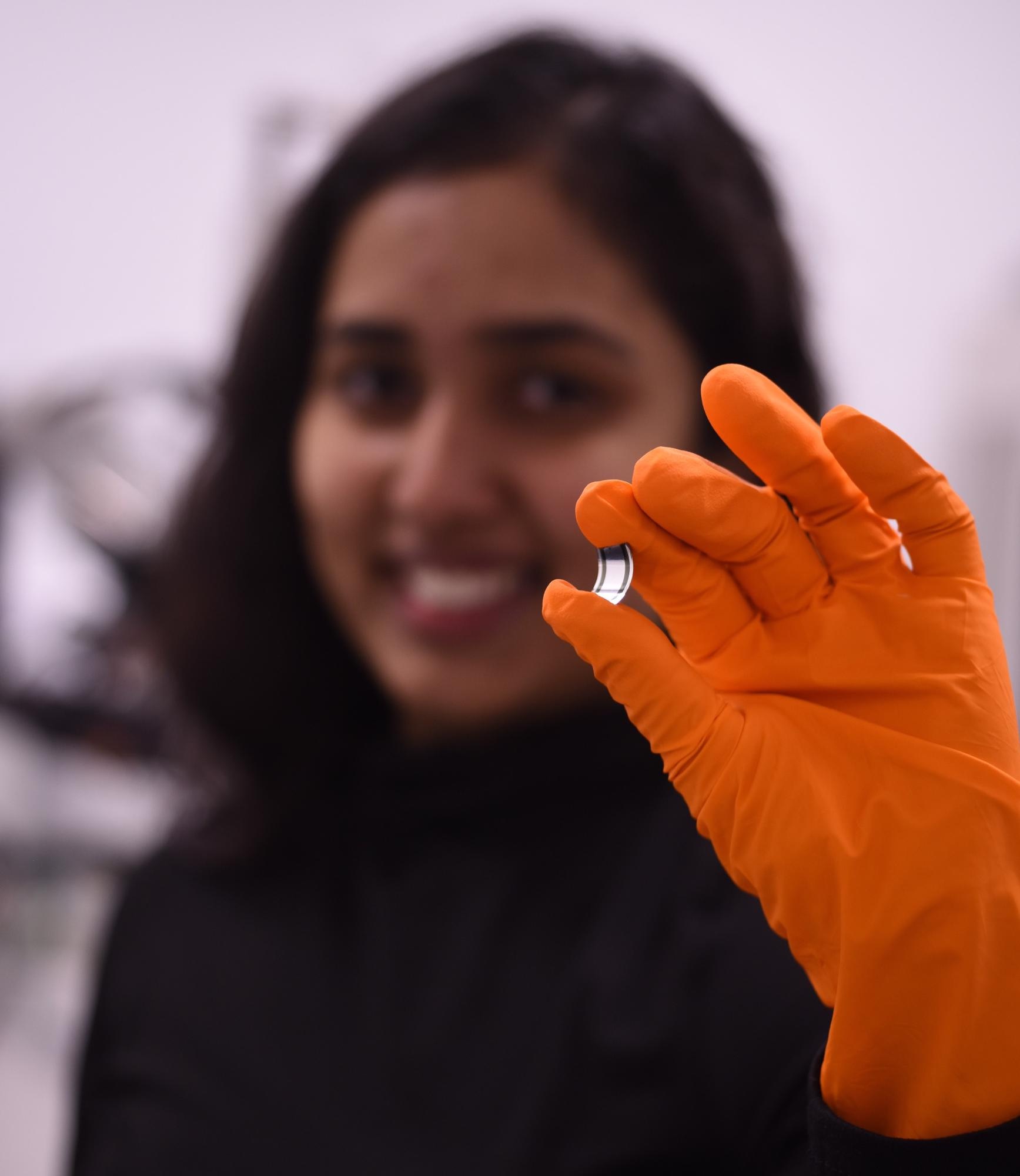

Image Credit: Dr. Imalka Jayawardena/University of Surrey

Polymers in particular have the possibility of getting entangled, much like how headphone wires get tangled in a pocket. We realized that there is a potential for realizing curved detectors if we select polymers with the right properties (i.e., their molecular weight or how long they are) and couple these with flexible substrates of the right thickness. This of course took me back to the mechanics of materials that I had studied as an undergraduate. Supported by mechanical, structural, and electrical measurements, we were able to identify the key design parameters for realizing these curved detectors. This work is the result of several key collaborations which allowed us to carry out the above measurements using facilities in the United Kingdom, Italy, and Switzerland.

What are the main differences between flat panel detectors and curved detectors?

For nearly three decades, digital imaging systems have relied on flat imaging detectors, also called flat-panel detectors. Before that, X-ray imaging was carried out using X-ray film which could be bent to follow the curvature of a subject. So far, there have been few successful demonstrations of using the bendability of X-ray film and the real-time imaging capability of flat-panel detectors. There is a gap and indeed a need for what we like to call “digital film”.

What are the benefits of producing curved X-ray detectors?

In most real-world applications, the objects we try to image are not flat and can have complex geometries. For example, think of the curves of the human body. While flat-panel detectors can perform well up to a certain point, they can lead to distortions and other aspects such as vignetting, which requires additional corrections. The use of curved detectors helps to bypass these issues and will hopefully lead to better diagnostics and treatment in medical imaging and cancer therapy and in many other sectors.

How will curved X-ray detectors provide a more accurate representation of X-ray dosages being delivered to patients?

Because of the curved nature of the human body, if X-ray doses are measured using a flat panel detector, additional geometric factors have to be taken into consideration to ensure that not only is the right dose delivered, but it is also delivered to the correct location. With curved detectors, it is possible to follow the contours of the human body more accurately which will improve treatment and also reduce the risk of secondary tumors. It could also reduce the financial burden on healthcare service providers.

Why has it been challenging so far to create flexible detectors?

Conventional electronic detectors are based on silicon processing technologies which are mainly compatible with rigid planar architectures and are too brittle to bend. While they can be thinned down, they are resulting in performance losses and additional issues such as higher material loss in the fabrication of such flexible detectors and increased costs which prevents their wider use.

Were there any key challenges in your research and how were these overcome?

One of the key challenges when I started my research was the very high dark currents that we observed in the previous generation of detectors. These dark currents were between 1,000 and 10,000 times higher than industrial requirements and were a key challenge that had to be overcome before we could evaluate the true potential of this system. Therefore, I initially worked on optimizing the detector architecture in such a way that industry-standard dark currents could be achieved. Initially, I thought of flipping the device architecture to realize a detector that was more tolerant to oxygen and moisture, both of which could degrade device characteristics. However, somewhat fortuitously, one of the deposition tools that I needed failed at an early stage and I was “playing” with an alternate strategy which led me to realize that this new architecture which I was hoping to adopt already had a beneficial structure at the nanoscale which allowed dark currents even lower than the industrial requirement to be realized. So, it was a combination of a factor out of our control as well as the careful observation that enabled us to overcome this challenge.

Is the curved X-ray detector technology scalable and could it be applied worldwide?

One of the key advantages of this system is that it is processed using what we call electronic inks. These offer more freedom to tune properties. Detectors can be coated using a similar process to how newspapers are printed, or using other common printing techniques can be used, such as inkjet printing. We even foresee the possibility of spray coating these materials. All these techniques allow coatings over large areas.

What are the next steps for the project?

I am, of course, looking to improve on the materials used for these detectors and we have already identified some promising candidates. Hopefully, we will be able to talk about this work soon. In addition, we are looking at different potential applications for this technology, including in medical, security and manufacturing. The University of Surrey is also working with Silverray, a spinout from the University, to look towards commercializing this technology.

Do you have any further research you would like to discuss?

We are looking into new material systems that fine-tune the properties even further and we already have some exciting results in hand. I am hopeful that this will be an interesting topic to discuss soon.

Where can readers find more information?

The research paper: https://doi.org/10.1002/advs.202101746

More information about Prabodhi Nanayakkara: https://www.surrey.ac.uk/people/maheshani-prabodhi-alwis-nanayakkara

About Prabodhi Nanayakkara

Prabodhi is currently a PhD student at Advanced Technology Insitute, University of Surrey, where she is supervised by Prof. Ravi Silva and Dr Imalka Jaywardena. Prior to her PhD, she graduated with a BSc Eng Hons in Materials Science and Engineering at the University of Moratuwa, Sri Lanka in 2017 and was awarded the Gold Medal for best performance in the field of Materials Science and Engineering.

Prabodhi is currently a PhD student at Advanced Technology Insitute, University of Surrey, where she is supervised by Prof. Ravi Silva and Dr Imalka Jaywardena. Prior to her PhD, she graduated with a BSc Eng Hons in Materials Science and Engineering at the University of Moratuwa, Sri Lanka in 2017 and was awarded the Gold Medal for best performance in the field of Materials Science and Engineering.

Prabodhi's research focuses on fabricating X-ray detectors by using organic-inorganic hybrid semiconductors such as bismuth oxide sensitized organic semiconductors. Through careful design, it is possible to achieve exceptional characteristics such as broadband sensitivities, ultra-low dark currents, low-voltage functionality, and conformable operation from such hybrid detectors.

She is working with several collaborators to optimize this detector concept to be implemented in potential applications such as dosimetry in radiotherapy.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.