Jul 6 2010

Naval Research Laboratory (NRL) scientists have developed new techniques of laser-machining for radiation detectors.

The Radiation Detection Section of the NRL’s Space Science Division is in the process of developing innovative radiation detectors that are based on trench- or hole-arrays in semiconductors. These detectors are known as three-dimensional (3-D) detectors.

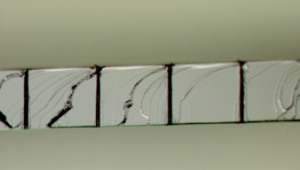

NRL - Laser Machined holes

NRL - Laser Machined holes

A hole-array, which is widely spaced, is desirable because it enables charge collection and lateral depletion. This helps to reduce the depletion voltage and thickness of the device; and as a result reduces the detector material cost and requirements for material quality.

The radiation detectors, which will be manufactured with the new techniques, will be smaller in size and consume less power than existing advanced detectors. The NRL team has developed various new methods to laser-machine the hole-arrays in various semiconductors such as Cadmium Telluride, Indium Phosphide, and Silicon. The new fabrication methodology is a crucial step for developing 3-D hole-arrays detector. The laser-machined holes have higher aspect ratio when compared to holes made with standard fabrication techniques.

The laser-micromachining of hole-arrays is being performed at the Institute of Nanoscience (NSI) of NRL, which has installed an Oxford E-Series laser micro-machining system recently.