An AFOSR-funded, Princeton-based professor, Dr. Craig Arnold, has been researching a new approach to optical nanopatterning, the forming of nanometer scale patterns on a substrate. This technology will have an impact on a variety of current and future Air Force needs.

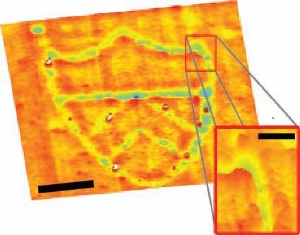

An AFOSR-funded, Princeton-based professor, Dr. Craig Arnold has been researching a new approach to direct-write optical nanopatterning that will have an impact on a variety of current and future Air Force needs. (Graphic Credit: Dr. Craig Arnold, Princeton University)

An AFOSR-funded, Princeton-based professor, Dr. Craig Arnold has been researching a new approach to direct-write optical nanopatterning that will have an impact on a variety of current and future Air Force needs. (Graphic Credit: Dr. Craig Arnold, Princeton University)

Standard nanopatterning creates highly precise patterns in controlled, clean and vibration-free environments. Many traditional DoD and AFOSR technologies use it in microelectronics, space-based platforms and small-scale space or remote platforms, and even in large-scale aircraft and munitions.

"The flexibility in the materials that we can work with and the size give us the ability to work with materials that are traditionally difficult to pattern: low temperature, non-vacuum compatible, or flexible substrates," said Dr. Arnold.

"All the results that we've shown have been performed in an office environment and on an optical bench without any vibration control. In the context of the Air Force, this has the implication that it could be possible to implement our technique to make repairs and modifications to materials in the field and even in a moving aircraft," he said.

"We use optical tweezers and a high power, pulsed ultraviolet laser. As a result, we can manipulate the beads all over the surface and can fire the pulsed laser in the locations we want to modify beneath the bead. Importantly, we can perform parallel nanopatterning on all kinds of surfaces," he said. Dr. Arnold's new patterning results eliminate major drawbacks of previous laser patterning techniques, namely slow speed and substrate damage, while achieving higher resolution.

Dr. Arnold emphasizes that he's grateful for support received from AFOSR program manager, Dr. Howard Schlossberg.

"This research grew out of our laser direct-write work that Howard has been funding for a few years. He allowed us to explore this nanopatterning avenue with much success, and we are very grateful for the resources and insight he provided, which helped to make this research possible," he noted.