Researchers have a new method for 3D nanoscale elemental analysis for ion-electron microscope systems, thanks to new research published in Nano Letters. This method permits the scientific community to advance their work, especially in the fields of energy storage and sustainability.

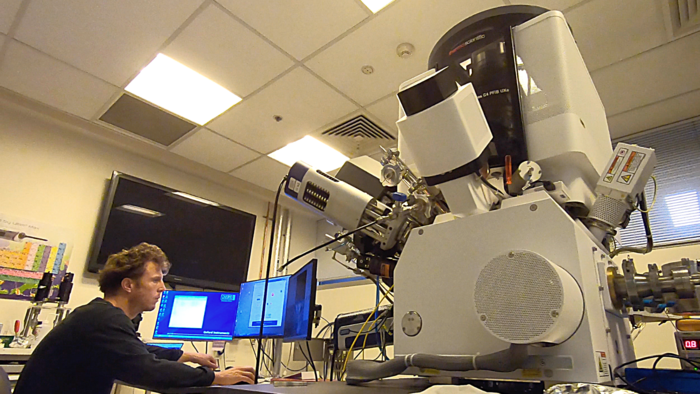

Dr. John Scott, University of Technology Sydney with the plasma FIB dual beam microscope. Image Credit: Milos Toth

A device that can be retrofitted to current focused ion beam systems (FIBS) was developed by researchers from Thermo Fisher Scientific, a renowned manufacturer of scientific instruments, in collaboration with the ARC Centre of Excellence for Transformative Meta-Optical Systems (TMOS).

The FIB is employed differently with this device, transforming it from a sputtering instrument to an engine for characterizing elements by gathering and analyzing the photons released during the sputtering procedure.

Other characterization methods can benefit from various enhancements made by this new method. In particular, it provides a resolution of 15 nanometers, which is significantly better than the electron-based EDX technique’s resolution of 1 micron. It can also find difficult-to-define elements like lithium and hydrogen.

The characterization of light elements has always been a challenge. This new device fills what was previously a gap in technology, paving the way for further scientific advancement. When that happens and researchers can investigate their problems with new techniques, new discoveries are made.

Garrett Budnik, Study Lead Author and Senior Scientist, Thermo Fisher Scientific

John Scott, a Study Co-Author and Post-Doctoral researcher at the University of Technology, Sydney stated, “This research was geared toward enabling other researchers to solve problems in an efficient way. Integrating elemental analysis as part of the sputtering process optimizes the characterization workflow, creating a better experience for all involved. We have developed this new technique so others can develop new technologies in a range of fields.”

Thermo Fisher Scientific developed Budnik’s projects based on their in-depth knowledge of gaps in the commercial market and their development of industry-leading technologies. He is the third employee of Thermo Fisher Scientific to collaborate with the university on an industry-relevant Ph.D.

Shared research between industry and academia are successful because they result in commercially-driven research. On their own, academic researchers might invest their energy in research that has little market appeal. Industry might develop rigorously-tested technology without fully understanding the fundamental science behind it. Together, they can make a significant contribution to society.

Milos Toth, Chief Inspector, ARC Centre of Excellence for Transformative Meta-Optical Systems

“This research was only possible because we had access to Thermo Fisher’s engineers. Our FIB is probably the most heavily modified microscope anyway and that’s because we could tap into the people who designed it, people who could help us tear it apart and put it back together,” Scott further stated.

When speaking about their research’s future, Budnik added, “We have pushed this detection system to its classical limit. It has been optimized to the point where the only place to go next is using metasurfaces. That is the natural next step.”

Journal Reference:

Budnik, G., et al. (2022) Nanoscale 3D Tomography by In-Flight Fluorescence Spectroscopy of Atoms Sputtered by a Focused Ion Beam. Nano Letters. doi:10.1021/acs.nanolett.2c03101