Scientists from Tokyo Metropolitan University led a team that cracked the conventional weight-versus-angular-resolution trade-off by developing historically lightweight optics for X-Ray space telescopes. Researchers etched complex patterns onto silicon wafers using Micro-Electro-Mechanical System (MEMS) technology, which could focus and collect X-Rays.

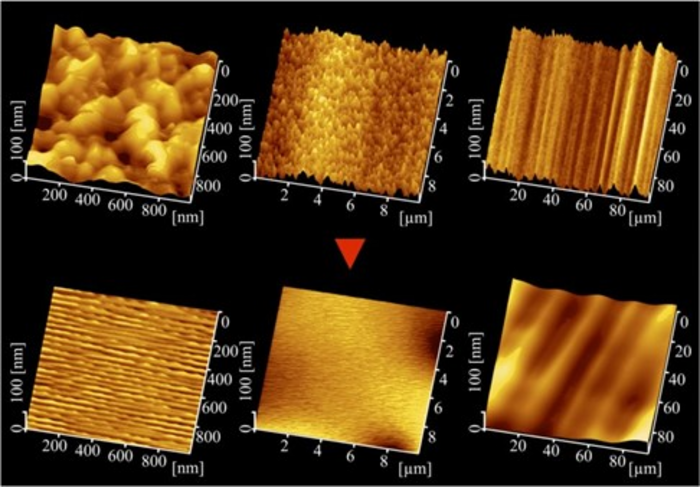

Before (top) and after 150 hours of annealing (bottom) at different length scales (left to right). It can be seen that the surface roughness measured using Atomic Force Microscopy is significantly reduced over a wide range of length scales. Image Credit: Tokyo Metropolitan University.

Before (top) and after 150 hours of annealing (bottom) at different length scales (left to right). It can be seen that the surface roughness measured using Atomic Force Microscopy is significantly reduced over a wide range of length scales. Image Credit: Tokyo Metropolitan University.

Researchers achieved ultra-sharp features by annealing and polishing, which might match the performance of present telescopes for a small fraction of the weight and cost substantially less to launch.

A crucial tool for studying and categorizing the wide variety of celestial entities that produce and interact with X-Rays, including the planet, is provided by X-Ray astronomy. The problem is that since the majority of X-Ray energy is absorbed by the atmosphere, telescopes and detectors must be sent into orbit. This entails a wide variety of restrictions; among them is the maximum weight of the apparatus.

The angular resolution, or the angle that two light sources may create with a detector and still be distinguished from one another, is one of the main characteristics of any astronomical observation optics. The issue with traditional X-Ray optics is that as resolutions increase, equipment weight increases. As a result of this, sending them into space is incredibly expensive.

The effective weight was 600 kg/m2 of effective area, even for the Hitomi telescope, which was introduced in 2016 and was regarded as being very light.

By developing a high-performance unit that weighs just 10 kg/m2, a team headed by Associate Professor Yuichiro Ezoe and Aoto Fukushima has now overcome this trade-off. Scientists patterned precise, detailed shapes onto silicon wafers that can steer and collect X-Rays using Micro-Electro-Mechanical Systems (MEMS) technology, a method meant to create minuscule mechanical actuators.

The design itself is based on the Wolter I geometry of existing X-Ray telescopes, which is a circular array of slits resembling tree rings that can push X-Rays coming from a restricted range of angles and concentrate them at a single spot. The way the team improved the patterning itself sets their work apart.

Deep reactive ion etching (DRIE) was used to etch the slits, and it was discovered that the surface roughness of the patterns could smear out the collection of the X-Rays, therefore lowering the resolution. As a result, they “annealed” the pattern by applying heat in a unique apparatus for improbable lengths of time.

The silicon atoms at the patterns’ surface were able to move around more with longer and longer annealing cycles, smoothing out any roughness and enhancing the telescope’s angular resolution. The rounded edges of the slots themselves were then straightened out by grinding and chemical polishing.

It is significant that the performance reported by the researchers corresponds to that of active telescopes. Due to its weight, it is well suited for the GEO-X mission, a satellite created to observe the Earth’s magnetosphere. A technical advancement may enable future missions to be launched into orbit at a vastly reduced cost. The team is aiming for a startlingly low overall weight of 50 kg.

The Japan Society for the Promotion of Science (Grant Numbers 19J20910, 20H00177, 21H04972, 21J12023) and the Toray Science Foundation both provided funding for this study.

Journal Reference:

Fukushima, A., et al. (2022) Improvement of imaging performance of silicon micropore X-ray optics by ultra-long-term annealing. Optics Express. doi.org/10.1364/OE.459774.