Reviewed by Alex SmithApr 8 2022

Scientists have formulated a new fabrication process that permits infrared (IR) glass to be integrated with a type of different glass and created into intricate minute shapes. The method can be used to develop intricate infrared optics that could render IR imaging and sensing a lot more accessible.

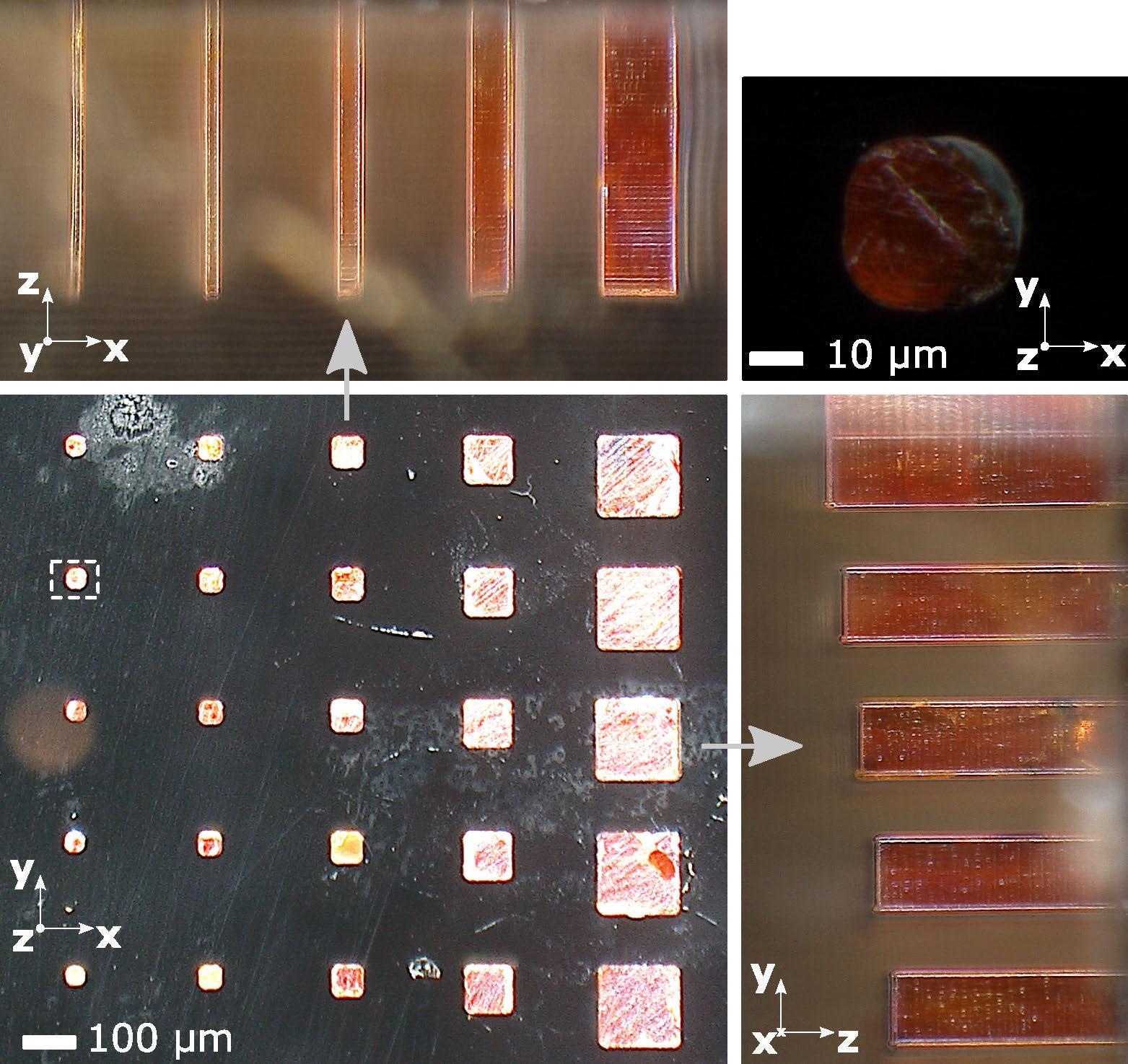

The researchers used their new fabrication approach to create various structures that combined chalcogenide IR glass with fused silica glass. These included a set of pillars with different dimensions. A white dotted rectangle in the above image indicates the smallest silica cavity used in this work. Image Credit: Yves Bellouard, Ecole Polytechnique Fédérale de Lausanne

The researchers used their new fabrication approach to create various structures that combined chalcogenide IR glass with fused silica glass. These included a set of pillars with different dimensions. A white dotted rectangle in the above image indicates the smallest silica cavity used in this work. Image Credit: Yves Bellouard, Ecole Polytechnique Fédérale de Lausanne

Glass that transmits IR wavelengths is essential for many applications, including spectroscopy techniques used to identify various materials and substances. However, infrared glasses are difficult to manufacture, fragile, and degrade easily in the presence of moisture.

Yves Bellouard, Study Lead, EPFL

The scientists illustrate their new method in the Optica Publishing Group journal Optics Express, which can be used to insert delicate IR glasses into a sturdy silica matrix.

The method can be implemented to form almost any interconnected 3D shape with structures measuring a micron or less. It functions with a broad range of glasses, providing a new method to tweak the properties of 3D optics with precise combinations of glass.

Our technique could open the door to a whole new range of new optical devices because it can be used to make infrared optical circuits and arbitrarily shaped IR micro-optics that were not previously possible because of the poor manufacturability of IR glass. These optics could be used, for example, for spectroscopy and sensing applications or to create an IR camera small enough to integrate into a smartphone.

Enrico Casamenti, Study First Author, EPFL

Merging Materials

The new fabrication method is based on earlier work wherein Bellouard's research team worked together with the team of Andreas Mortensen, also at Ecole Polytechnique Fédérale de Lausanne (EPFL), to formulate a technique for creating extremely conductive metals within an insulating 3D silica substrate.

"Our team began seeking innovative ways to achieve broadband light confinement in arbitrarily shaped 3D optical circuits," said Bellouard. "That's when we decided to explore the possibility of modifying a process that we first demonstrated using metal so that it could be used to produce structures that combine two types of glass."

For the new method, the scientists began by forming an arbitrarily shaped 3D cavity within a fused silica glass substrate using femtosecond laser-aided chemical etching. This uses the pulsed ray of a femtosecond laser—which can be concentrated to a spot approximately one micrometer wide—to modify the glass structure in a way that permits the exposed regions to be eliminated with a chemical like hydrofluoric acid.

After this is achieved, the minute cavity has to be packed with another material to develop a composite structure. The scientists achieved this by employing a miniaturized version of pressure-aided casting, wherein a second material is liquefied and pressurized so that it can flow and harden within the network of carved silica cavities.

The second material can be a glass, metal or any material with a melting point below that of the carved silica substrate and that does not react with silica glass.

Creating Complex Optics

"Our fabrication method can be used to protect IR glass, opening new avenues for micro-scale infrared optical circuits that are fully integrated in another glass substrate," said Bellouard. "Also, because fused silica and chalcogenide offer high refractive-index contrast, we can form these materials into IR waveguides that can transmit light much like optical fibers."

The scientists revealed the new technique by developing diverse complex shapes, including an EPFL logo, using a silica glass substrate and chalcogenide IR glass. They also demonstrated, with the help of contemporaries at ETH Zurich, that a few of the structures they formed could successfully be used for directing mid-IR light discharged from a quantum cascade laser at 8 microns. Only a few optical parts are available under this spectral range due to manufacturing challenges.

The search is ongoing for the capabilities of the new method in terms of merging various glasses. The team plans to test the composite parts in applications such as spectroscopy.

Journal Reference:

Casamenti, E., et al. (2022) Glass-in-glass infiltration for 3D micro-optical composite components. Optics Express. doi.org/10.1364/OE.451026.