Image Credit: ACS Nano

Researchers have developed waterproof lasers, overcoming the main limitations of perovskite lasers. The innovation has implications for a number of fields of science that have been previously prevented from gaining the full benefits of using these lasers, due to their propensity to break down in the presence of water and other common solvents.

Enhancing the Capabilities of Perovskite Lasers

A team of scientists at Peking University, in Beijing, China, has developed tiny lasers that are made from lead halide perovskites that extend their previous limitations of being impacted by common solvents. Led by Yu Ye and Lun Dai, the research team set out to improve on the capabilities of the lasers, which emit very strong, focused light, which studies have shown is easier to detect than the light emitted by fluorescent sources.

Due to these properties, the lasers have huge potential to be used in numerous applications within biochemistry, such as biosensing, cell tracking, and imaging, and acting as probes or labels. However, there had remained a major drawback of the lasers, being that perovskites are easily broken down by common solvents, such as water. This meant that applications of the lasers in biological environments has remained limited, due to the damage caused to the laser by introducing it to common biological systems.

Developing the Waterproof Coating

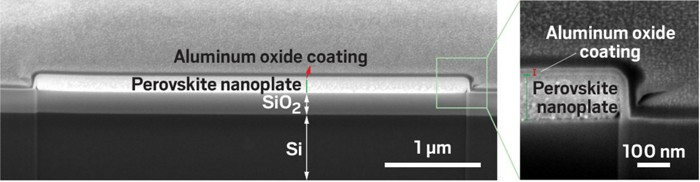

In a paper published recently in the journal ACS Nano, the Beijing-based team describes how they developed an aluminum oxide coating to protect the lead halide perovskites from solvent damage. The team has proven that its innovation gives the perovskite lasers waterproof properties through the addition of this protective coating.

To create the new, waterproof laser, the Peking University team deposited thin layers of cesium lead bromide on top of polydimethylsiloxane using chemical vapor deposition, to create nanosized plates of the material. They then transferred this nanoplate of cesium lead bromide to a silicon and silicon oxide substrate.

Following this, the team then coated the nanoplates using atomic layer deposition, increasing their thickness of just 113 to 165nm by 50nm through the addition of the aluminum oxide, creating a thick layer around the plates. Aluminum oxide is known for its properties in being easy to work with, and not affecting light transmission, key properties for its use in this project.

Finally, the finished product was then dipped in water to demonstrate that with the coating the laser could still successfully operate continuously for a one hour time period without showing detriments to its previously recorded functioning and efficiency.

In addition, the research team left the laser in the water for an entire month. During this time, the scientists switched the lasers off and on, recording its performance and efficiency each time. The results showed no decrease in performance over time, demonstrating the success of the waterproof coating they had developed. Other trials using thinner coatings had lead to a deterioration in the performance of the laser over periods of minutes to days.

The Next Steps

One of the lead researchers involved in the project, Yu Ye, explained that the tiny size of the single-crystal perovskite nanoplates along with the lasers superior light emission will lead to the development of their innovation in the construction of intracellular probes.

Therefore, the next step will be creating instruments that can investigate the activity within cells, utilizing the waterproof lasers to take measurements, with the assurance that they can be used for long periods without deterioration. The near future may see these lasers being developed in other areas of biochemistry, allowing researchers to see into cells in a way that has previously not been achievable.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.