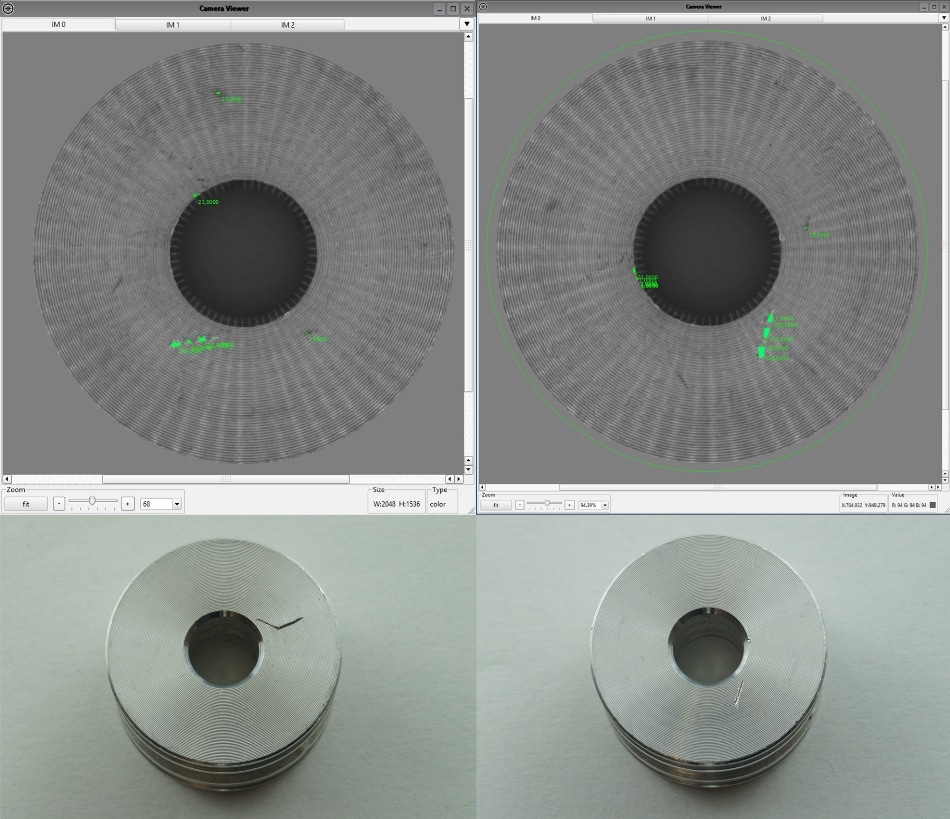

With the new Machine Learning Tool by EVT even scratches on metal surfaces can be detected.

Machine Learning for metal surfaces

Depending on the surface a simple camera setup with a dome light is sufficient to detect scratches. It is also possible to use the EyeMulti-Inspect setup, which already includes computing unit, camera, lens and lighting and is ready-to-use. The EyeMulti-Inspect is a robust setup for the industry with a housing, which also bears up under rough environments. Therefore the tracing of the component parts can be carried out on a conveyor belt. One only has to mount the sensor over the conveyor belt, connect the incremental encoder and determine the discharge chutes in the software.

Thanks to the EyeVision Software, this is completely carried out by the graphical user interface (GUI). The Machine Learning Tool can be called up and adjusted with a command in this user interface.

Machine Learning for non-solid component parts

But the system is not only for solid component parts. The separately controllable, integrated illumination systems allows to illuminate also difficult, non-solid component parts such as e.g. rubber parts. The Machine Learning Tool can then detect scratches and cracks and start the analysis.

Due to the flexibility of the software, it is easy to access different camera resolutions and to implement the ideal resolutions for the error detection.

Different Protocols available

The easy integration in existing plants or in new plants is made even easier with different protocols. Here Profinet, Modbus or TwinCat is available as standard interface. Also with the software any TCP/IP or UDP based protocol is available.

A extended toolbox for the illumination and lens components allows to adjust the product for different applications. There are different focal lengths and different types of illuminations such as dome light, back light, etc available.