May 20 2019

National Institute of Standards and Technology (NIST) physicists and partners have revealed an experimental, next-generation atomic clock—working at high “optical” frequencies—that is a lot smaller than usual, composed of merely three small chips plus secondary optics and electronics.

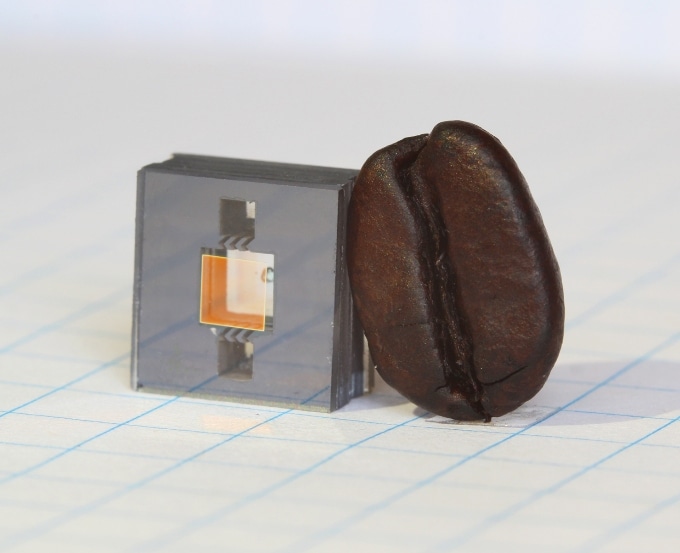

The heart of NIST’s next-generation miniature atomic clock—ticking at high “optical” frequencies—is this vapor cell on a chip, shown next to a coffee bean for scale. The glass cell (the square window in the chip) contains rubidium atoms, whose vibrations provide the clock “ticks.” The entire clock consists of three microfabricated chips plus supporting electronics and optics. (Image credit: Hummon/NIST)

The heart of NIST’s next-generation miniature atomic clock—ticking at high “optical” frequencies—is this vapor cell on a chip, shown next to a coffee bean for scale. The glass cell (the square window in the chip) contains rubidium atoms, whose vibrations provide the clock “ticks.” The entire clock consists of three microfabricated chips plus supporting electronics and optics. (Image credit: Hummon/NIST)

Illustrated in Optica, the chip-scale clock relies on the vibrations, or “ticks,” of rubidium atoms restricted in a miniature glass container, known as a vapor cell, on a chip. Two frequency combs on chips behave like gears to connect the atoms’ high-frequency optical ticks to a lower, extensively used microwave frequency that can be applied in applications.

The chip-based core of the new clock requires extremely little power (only 275 mW) and, with further technological progress, could possibly be built small enough to be held by hand. Chip-scale optical clocks similar to this could ultimately substitute traditional oscillators in applications such as telecommunications networks and navigation systems and act as backup clocks on satellites.

We made an optical atomic clock in which all key components are microfabricated and work together to produce an exceptionally stable output. Ultimately, we expect this work to lead to small, low-power clocks that are exceptionally stable and will bring a new generation of accurate timing to portable, battery-operated devices.

John Kitching, Fellow, NIST

The clock was fabricated at NIST with assistance from the California Institute of Technology (Pasadena, California), Stanford University (Stanford, California) and Charles Stark Draper Laboratories (Cambridge, Massachusetts).

Typical atomic clocks work at microwave frequencies, grounded on the natural vibrations of the cesium atom—the world’s principal definition of the second. Optical atomic clocks, working at higher frequencies, deliver better precision as they divide time into smaller units and possess a high "quality factor," which echoes how long the atoms can tick on their own, without external help. Optical clocks are projected to be the foundation for a future redefinition of the second.

In NIST’s innovative chip-scale atomic clock, the atoms were explored using a microwave frequency. The clock’s commercial versions have become an industry standard for portable applications needing high timing stability. But they require preliminary calibration and their frequency can drift over time, causing major timing flaws.

Compact optical clocks are a likely step up. Thus far, optical clocks have been large and complex, worked only as experiments by universities and metrological institutions.

Optical ticks in rubidium have been explored widely for use as frequency standards and are sufficiently accurate to be used as length standards. NIST’s rubidium vapor cell and the two frequency combs are microfabricated in the same manner as computer chips. This means they could support additional integration of optics and electronics and could be mass fabricated—a path toward commercially practical, compact optical clocks.

NIST’s chip-based optical clock has an instability of 1.7 x 10−13 at 4,000 seconds—about 100 times better than the chip-scale microwave clock.

The clock functions in this manner: The rubidium atoms’ tick at an optical frequency in the terahertz (THz) band. This ticking is used to steady an infrared laser, known as a clock laser, which is transformed to a gigahertz (GHz) microwave clock signal by two frequency combs behaving like gears. One comb, working at a THz frequency, spans a wide enough range to stabilize itself. The THz comb is synchronized with a GHz frequency comb, which is applied as a finely spaced ruler locked to the clock laser. The clock, therefore, creates a GHz microwave electrical signal—which can be measured by traditional electronics—that is steadied to the rubidium’s THz vibrations.

Going forward, the stability of the chip-based clock may be enhanced with low-noise lasers and its size decreased with more advanced electronic and optical integration.

The research is sponsored by the Defense Advanced Research Projects Agency and the NIST on a Chip program.