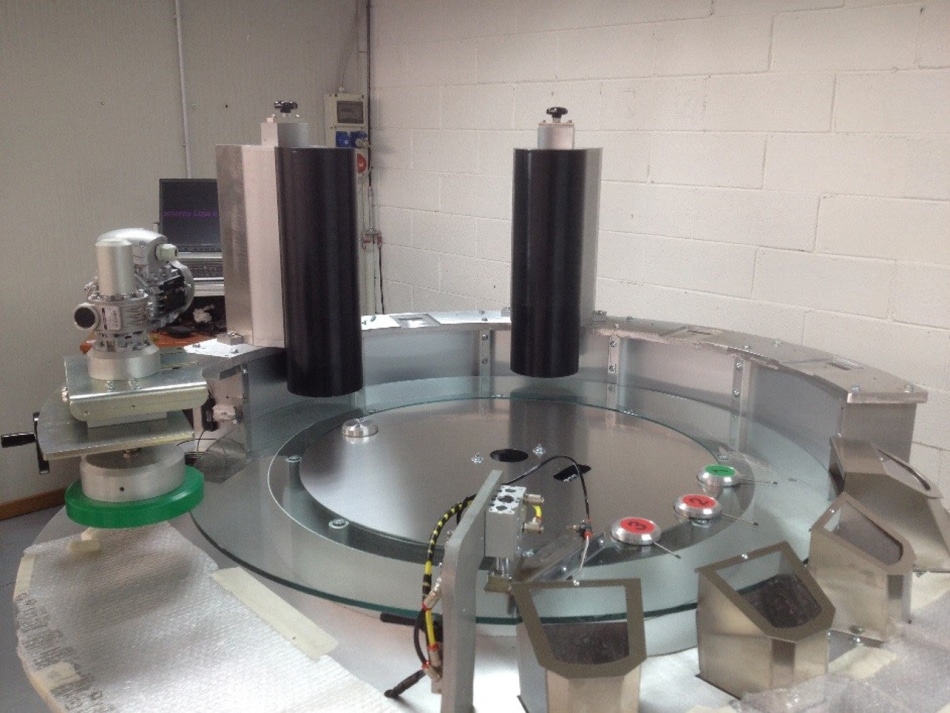

EyeMulti-Inspect is an extremely robust and industrial suitable hardware setup for the inspection of e.g. geometries and surfaces in testing consoles or inline in a production process.

The four different hardware setup are all supported by the EyeVision software and all inspection programs can be created with the EyeVision image processing software.

The user can therefore chose any EyeVision command, amongst them the Machine Learning Homogeneity Inspector command. It detects defects on surfaces, even on small O-rings, based on a Machine Learning algorithm. Additionally different errors on surfaces can be recognized with the flexible illumination control.

Concerning the hardware each sensor of the EyeMulti-Inspect contains:

- a camera suitable for the application, from VGA to 5 MPixel

- a special illumination setup

- an embedded PC for image analysis

- a control electronics which controls the illumination (light control), releases the camera trigger, and carries out the asset tracking.

Therefore it has the following advantages such as e.g. all parts are coordinated and the installation of the autonomous inspection system can be carried out fast and efficiently.

The illumination is most suitable for the setup and can be manually and automatically adjusted to height. Also there are different camera resolutions from VGA to 7 megapixel possible. In addition the EyeMulti-Inspect is built especially for rough and dirty environments.

EyeMulti-Inspect Measurement Sensor

The EyeMulti-Inspect Measurement Sensor is specially designed for the inspection of geometric values such as e.g. length, diameter, angle, etc. The sensor has a telecentric lens with an LED backlight and different cameras from VGA to 5 megapixel resolution.

The measurement accuracy is according to the setup approximately 0,005 to 0,02 mm.

EyeMulti-Inspect Surface Inspection Sensor

The Surface Inspection Sensor recognizes with the Homogeneity Inspector Machine Learning algorithm any kind of surface damage. It has a multi-level illumination for ideal contrast spread consisting of dome light, side light, dark field illumination and when necessary a backlight.

EyeMulti-Inspect Side Inspection Sensor

The Side Inspection Sensor inspects parts from the side. With six to eight single camera sensors the component part is captured from the side. And with a three-level illumination with darkfield illumination the side is illuminated with the perfect contrast.

EyeMulti-Inspect 3D Sensor

3D Sensors are used when the contrast is not enough or in case real hight values are needed. Teh EyeMulti-Inspect 3D Sensor can capture up to 1000 profiles per second with a height resolution of 0,005 mm. The profiles are assembled into a matrix image and the gray values represent the height values.