This is an automated optical 3D imaging and metrology system for submicron level accurate measurements on any material. It is a stand-alone system used in state-of-the-art R&D laboratories, smart manufacturing, and quality control.

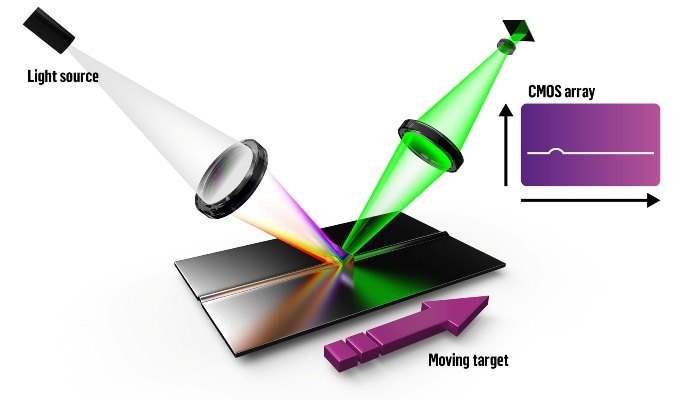

Line Confocal Imaging (LCI) technology used in UULA enables customers to model the most demanding surfaces and shapes, even mirror-like, curved and transparent objects. UULA’s LCI sensor detects millions of 3D points per second, and it can distinguish irregularities of less than one micron. The UULA consists of a light source and a CMOS array which are arranged in an angle to each other.

The EyeVision software can carry out different measurements on the captured point cloud and profile. The Metrology command set as well as the 3D Profile commands can be applied to the scans. The Profile Match command for example can compare previously configured profiles with the scanned profile and therefore can detect defect profiles.

The UULA is the solution for challenges such as e.g. that devices are becoming smaller and thinner and the materials and shapes designed more complex. In addition it has been difficult carrying out sufficiently accurate measuring during actual production, resulting in costly halts.

Compared to the old measuring methods, with the special 3D technology „Line Confocal Imaging (LCI)“ laboratory level accuracy is achievable in an industrial environment. The LCI technology delivers accurate data and high-resolution 3D imaging of metal, glass, paper or plastic surfaces.

The LCI delivers automated, high-speed and high-precision scans of challenging surfaces and shapes, such as mirror-like, curved or multi-layered transparent objects.

Comparison with Lasertriangulation:

|

LCI

|

|

Laser

|

|

yes ←

|

Glossy material

|

→ limited

|

|

yes ←

|

Mirror-like surface

|

→ no

|

|

yes ←

|

Transparent material

|

→ limited

|

|

Excellent ←

|

Tolerance for surface angle variations

|

→ limited

|

|

yes ←

|

Curved transparent surface

|

→ limited

|

|

yes ←

|

Multi-layered transparent object

|

→ no

|

|

<1 µm

|

Precision

|

→ limited

|

|

yes ←

|

Speckle free

|

→ no

|

|

yes ←

|

Simultaneous 3D and 2D imaging

|

→ no

|

What can UULA measure?

The UULA can measure 3D topography and dimensions. It can make tomographic imaging of transparent objects as well as high-precision 2D imaging with extended sharp focus range.

For which industries can the LCI be applied?

Consumer electronics

The UULA can measure a curved glass display of a smart phone to detect the shape of the glass. It can also measure the gap and offset between the glass and the frame.

Medical devices

The UULA can scan a sheet of printed biosensors. The 3D dimensions and the surface roughness of the active area can be detected. Also the thickness of conductive ink can be measured.

Microfluidics

The UULA can scan transparent microfluidics chip and detect 3D dimensions of the microchannels. Also height and width of the channels can be measured.

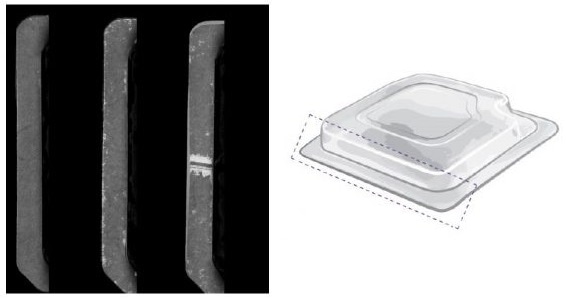

Advanced packaging

The seal quality can be detected from the 2D intensity images. The quality of the samples range from good (left) to failed (right).