Nov 30 2018

Scientists reveal two new methods to forming three-dimensional (3D) images using X-rays that could enhance disease-screening, study of very rapid processes and enable analysis of the properties of materials and structural information of opaque objects with unparalleled detail.

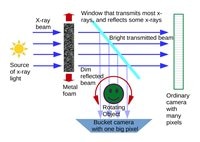

Ghost imaging x-ray tomography produces 3D images by correlating two beams that do not carry any meaningful information about the object. One beam encodes a random pattern that acts as a probing reference and the other passes through the sample. (Image credit: David Paganin, Monash University)

Ghost imaging x-ray tomography produces 3D images by correlating two beams that do not carry any meaningful information about the object. One beam encodes a random pattern that acts as a probing reference and the other passes through the sample. (Image credit: David Paganin, Monash University)

The scientists explain their approaches to 3D imaging with X-rays in two papers in Optica, The Optical Society's journal for high-impact research. One technique might decrease X-ray doses needed in certain types of preventative medical imaging, such as breast cancer screening. The other technique might enable 3D imaging of delicate biological samples or the investigation of very fast processes, such as the types of interactions that take place during space-debris impacts, to accelerate development of more durable materials.

Due to their short wavelength and high energy, X-rays can pass through materials that visible light cannot. Although 3D X-ray images can be acquired, existing approaches are limited in application because they require extended exposures to damaging X-rays.

In humans, excessive radiation from medical X-ray imaging can raise cancer risk, which limits how frequently they can be screened with 3D mammography and other 3D X-ray technologies. Very high-energy X-rays used to explore the complete make-up of materials, and biological samples frequently cannot be used because the samples would be damaged after a single exposure.

3D ghost tomography with X-rays

Scientists guided by Andrew Kingston of the Australian National University along with a team at the European Synchrotron Radiation Facility (ESRF) in France have shown for the first time that the unconventional imaging method called ghost imaging can be used to attain 3D X-ray images of the interior of objects opaque to visible light.

“Because of the potential for significantly lower doses of X-rays with 3D ghost imaging, this approach could revolutionize medical imaging by making X-ray screening for early signs of disease much cheaper, more readily available and able to be undertaken much more often,” said the paper’s senior author, David Paganin, from Monash University, Australia. “This would greatly improve early detection of diseases including cancers.”

Ghost imaging works by correlating two beams—in this case, X-ray beams—that do not independently possess any significant information about the object. One beam encodes a random pattern that serves as a reference and at no time directly probes the sample. The other beam passes through the sample.

The scientists formed random X-ray patterns by shining a bright beam of X-ray light through a metal foam, which is similar to a sponge made of metal. They took a 2D image of this random beam, and then passed an extremely weak copy of it through the sample. A large-area single-pixel detector captured X-rays that were sent through the sample. The process was repeated for numerous illuminating patterns and sample-object orientations to create a 3D tomographic image of the object’s internal structure.

As a proof-of-concept experiment, the scientists performed ghost X-ray tomography on an aluminum cylinder having a diameter of 5.6 mm and having two holes of less than 2.0 mm in diameter. They were able to generate 3D images with 1.4 million “voxels”—a term for 3D pixels—with a resolution, or voxel side-length, of 48 millionths of a meter.

X-ray ghost imaging, especially ghost tomography, is a completely new field that needs to be explored and developed much further. With more development, we envision ghost X-ray tomography as a route to cheaper and, therefore, much more readily available 3D X-ray imaging machines for medical imaging, industrial imaging, security screening, and surveillance.

Andrew Kingston, Researcher, Australian National University.

3D images from a single exposure

A research team from the Paul Scherrer Institute in Switzerland, led by Marco Stampanoni, along with a team from the Deutsches Elektronen-Synchrotron (DESY) in Germany and the ESRF, obtained 3D images using high-brilliance X-ray sources. Their new method uses a single exposure, or shot, to gain 3D information from X-rays one hundred billion times brighter than a hospital X-ray source. The rays can only be generated at dedicated synchrotron facilities.

“High-brilliance X-ray sources are quite useful for biology and materials science because they can probe faster processes and higher resolutions than other X-ray sources,” said the paper’s first author Pablo Villanueva-Perez from DESY. “Because the power of these sources can destroy the sample after a single pulse, current 3D imaging using the full power of these sources requires multiple identical copies of a sample.”

The new method can make the measurements essential to form a 3D image before destroying the sample, so it could be beneficial for examining the mechanics of delicate biological samples such as living insects or analyzing the internal 3D structure of intact proteins or viruses.

The new single-shot method uses a crystal to split one incoming X-ray beam into nine beams that concurrently illuminate the sample. Using detectors oriented to record information from each beam enables scientists to obtain simultaneously nine different 2D projections of a sample object before it is destroyed by the strong X-ray probe beams.

The scientists used the method to image a moth, which revealed the potential for researching insect mechanics with 3D microscale resolution at speeds ranging from microseconds to femtoseconds. They also demonstrated that they could realize nanoscale resolution by imaging a gold nanostructure.

We would like to combine our technique with the unique capabilities of the European X-Ray Free-Electron Laser Facility, the first facility to deliver X-ray pulses at a rate of one million pulses per second. This could allow 3D exploration of fast processes at speeds of millions of frames per second.

Pablo Villanueva-Perez, Researcher, Deutsches Elektronen-Synchrotron (DESY).

The scientists aim to use their single-shot multi-projection imaging method to better comprehend insect biomechanics, which could inspire new engineering platforms. They are also keen to study new, lighter materials that might lower the consumption of fuel for vehicles and plan to inspect the rapid processes that take place when space debris hits satellites, which could assist in the development of protective materials.