Nov 15 2018

The age of glass lenses may be declining in optics. In the recent past, various types of ultrathin materials that could substitute the thick glass lenses currently used in cameras and imaging systems have been designed, constructed, and tested by engineers and physicists.

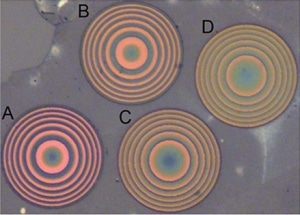

Four ultrathin metalenses developed by University of Washington researchers and visualized under a microscope. (Image credit: Liu et al., Nano Letters, 2018)

Four ultrathin metalenses developed by University of Washington researchers and visualized under a microscope. (Image credit: Liu et al., Nano Letters, 2018)

Incidentally, these engineered lenses—called metalenses—are not made of glass but rather they contain materials built at the nanoscale into series of fin-like structures or columns. Such formations are capable of interacting with the incoming light and directing it towards one focal point for imaging purposes.

However, while metalenses are relatively thinner in comparison to glass lenses, they still depend on “high aspect ratio” structures, wherein the height of the fin-like structures or columns is much greater than their thickness, which makes them susceptible to falling or collapsing over. Until now, these structures have invariably been close to the wavelength of light they are interacting with in thickness.

Now, in a paper featured in the journal Nano Letters, researchers from the University of Washington (UW) and the National Tsing Hua University in Taiwan have reported that they have successfully developed functional metalenses that measure one-tenth to one-half the width of the wavelengths of light that they focus. The new metalenses, made from layered 2D materials, had a thickness of just 190 nm, which is less than 1/100,000ths of an inch thick.

This is the first time that someone has shown that it is possible to create a metalens out of 2D materials.

Arka Majumdar, Assistant Professor of Physics and of Electrical and Computer Engineering and Study Co-Corresponding Author, University of Washington.

Majumdar added that their new design principles can be used for developing metalenses that have more tunable and complex features. He is also a faculty researcher with the UW’s Molecular Engineering and Sciences Institute and Institute for Nano-Engineered Systems.

For years, Majumdar’s group has been examining the design principles of metalenses and earlier developed metalenses for full-color imaging. However, the difficulty in this project was to resolve an intrinsic design constraint in metalenses: if a metalens material had to interact with light and realize optimal imaging quality, then the material should have approximately the same thickness as the wavelength of light in that material. In the mathematical context, this limitation makes sure that a full-zero to two-pi phase shift range is attainable, which allows designing any kind of optical element. For instance, a metalens for a 500-nm lightwave—which is a green light in the visual spectrum—would need to have a thickness of approximately 500 nm, albeit this thickness can reduce as the material’s refractive index increases.

Along with his team, Majumdar successfully synthesized functional metalenses that were relatively thinner when compared to this hypothetical limit—that is, one-tenth to one-half the wavelength. The researchers initially developed the metalens from sheets of layered 2D materials and utilized extensively researched 2D materials like molybdenum disulfide and hexagonal boron nitride. One atomic layer of these materials offers an extremely small phase shift, which is not appropriate for efficient lensing. Therefore, the researchers applied many layers to increase the thickness, even though the thickness continued to be too small to achieve a full two-pi phase shift.

We had to start by figuring out what type of design would yield the best performance given the incomplete phase.

Jiajiu Zheng, Doctoral Student in Electrical and Computer Engineering and Study Co-Author, University of Washington.

In order to overcome the limitation, the researchers used mathematical models that were initially developed for liquid-crystal optics. These models, in tandem with the metalens structural elements, enabled the team to realize high efficiency even if the entire phase shift is not covered. The researchers then tested the efficacy of the metalens by utilizing it to capture varied test images, such as the block letter W and the Mona Lisa. They also showed how the metalens can be stretched to adjust the lens’ focal length.

Besides realizing a whole new method for designing metalens at record-thin levels, the researchers think that their experiments could pave the way for developing novel devices for optics and imaging entirely from 2D materials.

These results open up an entirely new platform for studying the properties of 2D materials, as well as constructing fully functional nanophotonic devices made entirely from these materials.

Arka Majumdar, Assistant Professor of Physics and of Electrical and Computer Engineering and Study Co-Corresponding Author, University of Washington.

Moreover, it is possible to transfer these materials on any substrate, such as flexible materials, thus potentially leading to the development of flexible photonics.

Chang-Hua Liu, the lead and co-corresponding author on the paper, started this work as a UW postdoctoral researcher and is currently a faculty member at the National Tsing Hua University in Taiwan. Other co-authors are doctoral students Taylor Fryett, Shane Colburn, and Yueyang Chen in the Department of Electrical and Computer Engineering; and Xiaodong Xu, a UW professor of physics and of materials science and engineering. The researchers’ prototype metalenses were all developed at the Washington Nanofabrication Facility, a National Nanotechnology Coordinated Infrastructure site on the UW campus.

The U.S. Air Force Office of Scientific Research, the National Science Foundation, the Washington Research Foundation, the M.J. Murdock Charitable Trust, GCE Market, Class One Technologies, and Google funded the study.