Apr 20 2018

Researchers have developed a new method to write and erase magnets in an alloy by applying a laser beam. The result was an unexpected effect. The study was performed by researchers from the Helmholtz-Zentrum Dresden-Rossendorf (HZDR), an independent German research laboratory¸ along with colleagues from the University of Virginia in Charlottesville, USA and the Helmholtz-Zentrum Berlin (HZB).

The process’ reversibility presents new opportunities in the fields of data storage, material processing, and optical technology. The study, reported in the journal ACS Applied Materials & Interfaces, is the result of an international effort that involved teams from the US, and Berlin and Dresden in Germany.

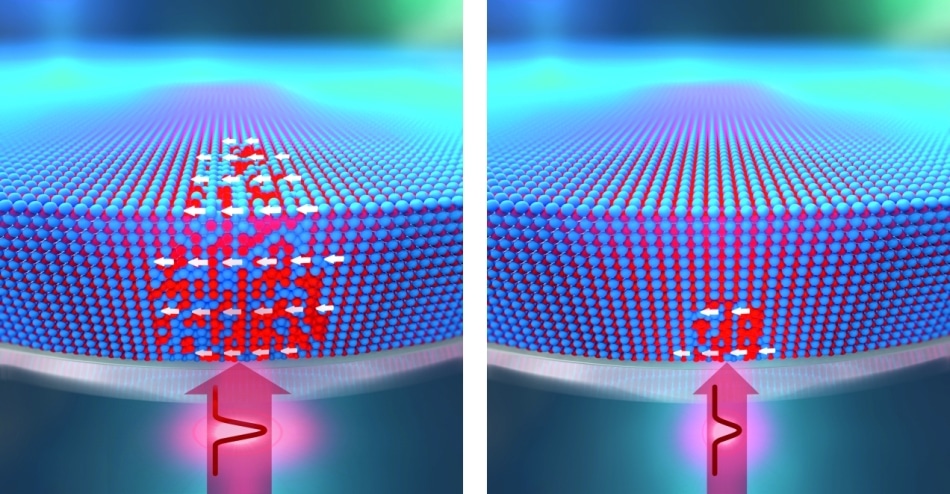

Laser light for writing and erasing information – a strong laser pulse disrupts the arrangement of atoms in an alloy and creates magnetic structures (left). A second, weaker, laser pulse allows the atoms to return to their original lattice sites (right). (Image credit: Sander Münster / HZDR)

Laser light for writing and erasing information – a strong laser pulse disrupts the arrangement of atoms in an alloy and creates magnetic structures (left). A second, weaker, laser pulse allows the atoms to return to their original lattice sites (right). (Image credit: Sander Münster / HZDR)

The HZDR team investigated an alloy of aluminum and iron. This alloy serves as an attractive prototype material because its magnetic behavior can be fully transformed by making slight changes to its atomic arrangement.

The alloy possesses a highly ordered structure, with layers of iron atoms that are separated by aluminum atomic layers. When a laser beam destroys this order, the iron atoms are brought closer together and begin to behave like magnets.

Rantej Bali, HZDR Physicist

Bali and his colleagues first created a thin alloy film on top of the transparent magnesia through which the thin film was irradiated by a laser beam. Then, along with the HZB team, the researchers pointed a well-focused laser beam with a pulse of 100 femtoseconds (a femtosecond is a millionth of a billionth of a second) at the iron-aluminum alloy which resulted in the formation of a ferromagnetic area. The magnet was deleted by shooting laser pulses at the same region again, but this time at reduced laser intensity.

About half of the earlier level of magnetization was retained with just a single laser pulse at reduced intensity, while the magnetization disappeared completely with a series of laser pulses. These findings were made at the HZB-run Bessy II synchrotron with the help of a microscope that studies magnetic contrast by deploying soft x-rays.

In collaboration with a research team from the University of Virginia in Charlottesville, USA, the researchers were able to explain the mechanism that occurs in the alloy during this process. The simulations of the US team demonstrate that ferromagnetic state is formed when the thin-film material is heated up and melted by the ultra-short laser pulse throughout the surface to the transparent magnesia interface.

When the alloy cools down, it enters a “supercooled liquid” state, wherein it continues to be in molten form even after the temperature drops below the melting point. The absence of nucleation sites contributes to this state. Nucleation sites are tiny locations, where the atoms can start to arrange into a lattice. Moreover, the temperature continues to decrease as the atoms move around in the supercooled state looking for nucleation sites.

The atoms in the supercooled state must ultimately form a solid lattice, and just like the musical chair game, the aluminum and iron atoms become trapped in random positions inside the lattice. The entire process takes just a few nanoseconds, and a magnet is rendered by the haphazard arrangement of atoms.

The atoms are rearranged into a well-ordered structure by the same laser, but with a reduced intensity. Only thin layers of the film are melted by the weaker laser shot, producing a molten pool that sits on the solid alloy. The solid portion of the film begins to regrow within a nanosecond following melting, and once the temperature decreases below the melting point.

The atoms, on their part, quickly rearrange from the chaotic liquid structure to the crystal lattice. With the temperature still being sufficiently high and the lattice already formed, the atoms have adequate energy to diffuse via the lattice and separate into iron and aluminum layers. Ph.D. student Jonathan Ehrler summarizes: “To write magnetic areas, we have to melt the material from the surface down to the interface, while to delete it, we only need to melt a fraction of it.”

In additional experiments, the researchers are now planning to study this process in other ordered alloys and are also intending to study the effect of a combination of various laser beams. Patterned magnetic materials could be generated over large areas with interference effects. “The remarkably strong changes to the material property may well lead to some interesting applications,” reckons Bali. Lasers are employed for a wide range of applications in industry, for example, in material processing. The findings may also give way to new possibilities in data-storage and optical technologies.