Nov 8 2017

Scientists at MIT and several other institutions have created a method for developing photonic devices — similar to electronic devices but based on light instead of electricity — that can stretch and bend without damage. The devices could find uses in monitoring and diagnostic systems that could be fixed to the skin or implanted in the body, bending easily with the natural tissue, or in cables to connect computing devices.

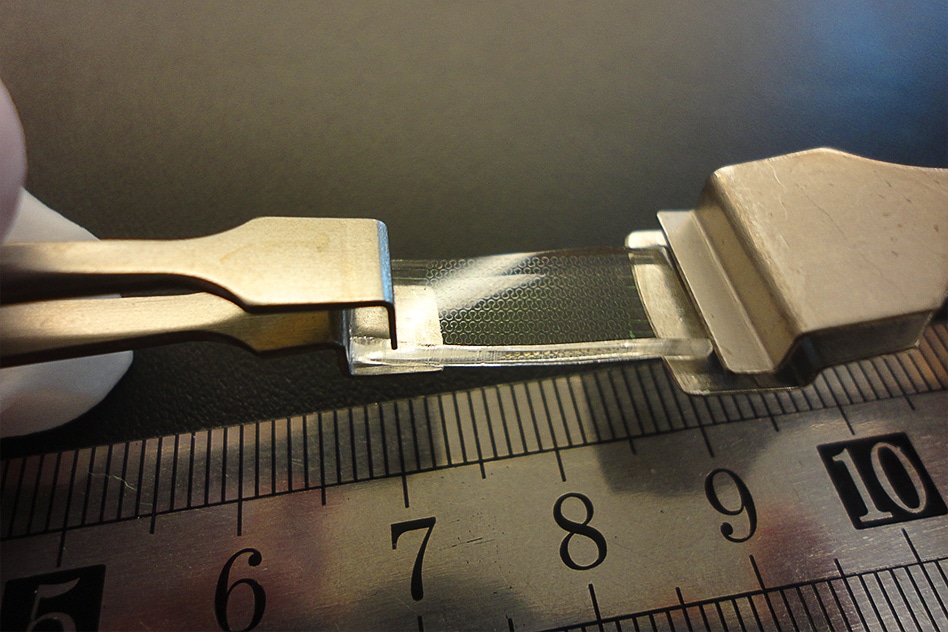

A new material produced by Juejun Hu and his team can be repeatedly stretched without losing its optical properties. Courtesy of the researchers

A new material produced by Juejun Hu and his team can be repeatedly stretched without losing its optical properties. Courtesy of the researchers

The research findings, which involve the use of a specialized type of glass known as chalcogenide, are explained in two papers by MIT Associate Professor Juejun Hu and over a dozen others at MIT, the University of Central Florida, and Universities in France and China. The paper is scheduled for publication soon in Light: Science and Applications.

According to Hu, who is the Merton C. Flemings Associate Professor of Materials Science and Engineering, many people are interested in the potential of optical technologies that can bend and stretch, particularly for applications such as skin-mounted monitoring devices that might directly sense optical signals. For instance, such devices could simultaneously detect blood oxygen levels, heart rate and even blood pressure.

Photonics devices directly process light beams, using systems of mirrors, LEDs and lenses produced with the same types of processes employed to manufacture electronic microchips. Using light beams instead of a flow of electrons may have advantages for various applications; for instance, if the original data is light-based, optical processing prevents the requirement for a conversion process.

However, most current photonics devices are produced from rigid materials on rigid substrates, Hu said, as a result have an “inherent mismatch” for applications that “should be soft like human skin.” However, most soft materials, including many polymers, have a low refractive index, which causes a poor ability to restrict a light beam.

Rather than using such flexible materials, Hu and his team took a new approach: They created the stiff material — in this case a thin layer of a kind of glass known as chalcogenide — into a spring-like coil. Just like steel can be made to bend and stretch when formed into a spring, the design of this glass coil enables it to bend and stretch freely while maintaining its required optical properties.

You end up with something as flexible as rubber, that can bend and stretch, and still has a high refractive index and is very transparent.

Juejun Hu, Associate Professor, MIT

Experiments have revealed that such spring-like configurations, directly made on a polymer substrate, can go through thousands of stretching cycles without detectable degradation in their optical performance. The team made a range of photonic components, connected by the flexible and spring-like waveguides, all in an epoxy resin matrix, which was made more flexible around the waveguides and stiffer near the optical components.

Other types of stretchable photonics have been created by inserting nanorods of a stiffer material in a polymer base; however, these require additional manufacturing steps and are not compatible with current photonic systems, Hu said.

These types of flexible, stretchable photonic circuits could also be advantageous for applications where the devices have to stick to the uneven surfaces of some other types of material, such as in strain gages. According to Hu, optics technology is extremely sensitive to strain and it could detect deformations of below one-hundredth of 1%.

This study is still in initial stages; Hu’s team has showed only single devices at a time until now.

For it to be useful, we have to demonstrate all the components integrated on a single device.

Juejun Hu, Associate Professor, MIT

Work is in progress to develop the technology to that point in order that it could be commercially used, which, according to Hu, could take two to three years.

In another paper reported last week in the Nature Photonics journal, Hu and his team have developed a new method for combining layers of photonics, made up of chalcogenide glass and two-dimensional materials such as graphene, with traditional semiconductor photonic circuitry. Current methods for combining such materials require them to be prepared on one surface and then peeled off and moved to the semiconductor wafer, which adds significant complexity to the process. Instead, the new method enables the layers to be produced directly on the surface of the semiconductor, at room temperature, allowing for simplified production and more precise alignment.

The method can also use the chalcogenide material as a “passivation layer,” in order to protect 2D materials from degradation due to ambient moisture, and as a way to control the optoelectronic features of 2D materials. This method is generic and could be expanded to other promising 2D materials besides graphene, to increase and accelerate their integration with photonic circuitry, Hu said.

The research team also included MIT postdocs Lan Li and Hongtao Lin, MIT Professor Jing Kong, and others at the Xiamen University and Chongqing University in China, the University of Southampton in the UK, Universite Paris-Sud in France, University of Texas, and the University of Central Florida. The National Science Foundation provided support and the MIT Microsystems Technology Laboratories was used for the research.