Jul 12 2017

A new computational design tool allows users to transform any 3D shape into a collapsible telescoping structure.

New mathematical techniques formulated by a team of Researchers at Carnegie Mellon University capture the intricate and diverse properties of such structures, which are valuable for a range of applications in 3D fabrication and robotics - mainly where mechanisms must be easily deployable and compact in size.

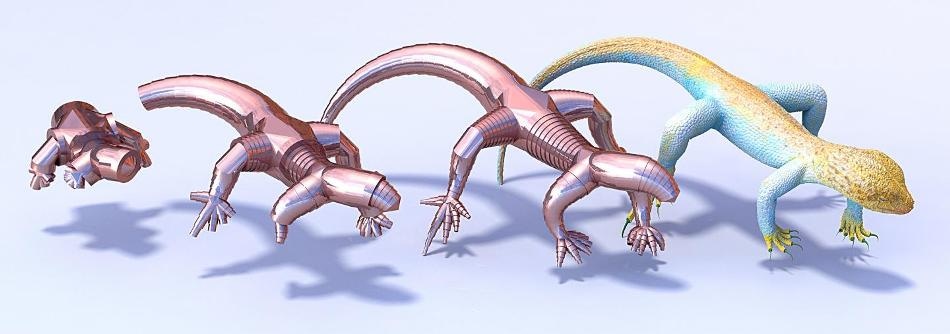

New computational tool automates design of telescoping structures that provide compact storage and rapid deployment. Shown here: a complex telescoping lizard expands to many times its original volume, serving as a stress test of the method. (CREDIT - (Chris Yu/Carnegie Mellon University)

New computational tool automates design of telescoping structures that provide compact storage and rapid deployment. Shown here: a complex telescoping lizard expands to many times its original volume, serving as a stress test of the method. (CREDIT - (Chris Yu/Carnegie Mellon University)

The research paper titled, "Computational Design of Telescoping Structures," written by Carnegie Mellon Professors Stelian Coros and Keenan Crane ,and PhD Student Christopher Yu, will be presented at the annual SIGGRAPH conference, held between 30th July and 3rd August in Los Angeles. Every year the conference showcases the most innovative in computer graphics research and interactive methods worldwide.

Traditional telescopes are flawlessly straight, and their capacity to expand from a compact form into a much larger structure has been extensively exploited in engineering design. Thus far, however, there has not been systematic research of the types of shapes that can be modeled by telescoping structures, nor useful tools for telescopic design. At a recent maker faire, the team came across a set of retractable toy claws, built based on the popular X-Men character, Wolverine. Inspired by the curved shape of the claws, they began to explore the idea of automating the design of telescoping structures, exploring a wide range of shapes that could come out of a basic telescope model.

Besides the example of a common straight telescope used for star gazing, other collapsible, deployable structures can benefit from a twisted or curved telescoping design: camping equipment such as large outdoor structures or tents used for music festivals; a heart stent that is tiny at the point of insertion but expands once it is surgically positioned; or a robotic arm that can retract itself into a cylinder shape the size of a Coke can, enabling user versatility and portability.

Among deployable mechanisms, telescopes are very interesting. Once you expand them, they are very flexible and you can make a lot of different shapes, all with the same telescope. We wanted to know what are all the possible shapes you can make from a telescoping structure.

Keenan Crane, Co-Author and Assistant Professor of Computer Science and Robotics, Carnegie Mellon

The mathematical model of telescoping structures created by the team begins with three common-sense requirements: each shell must be manufacturable from rigid material (like metal), the telescope should be able to extend and contract without bumping into itself and there must not be any empty wasted space between nested pieces. These standard requirements led to an important geometric insight: the complicated mechanical description of a telescope can be replaced by simple geometric curves that display a constant amount of bend but arbitrary "twist," considerably generalizing the straight telescopes found in common engineering designs. The team effectively prototyped applications in robotics and 3D fabrication using their novel system to build both a flexible, controllable robot arm and a tent-like structure that grows to several times its initial volume.