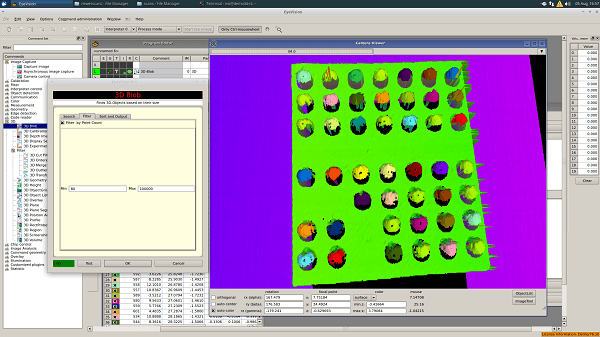

Besides the inspection of the correct position of pins, the EyeScan AT 3D sensor – together with the EyeVision image processing software – can also check for the flawlessness and position of balls on a Ball-Grid-Array.

The connectors of BGAs can be inspected with the 3D sensor for various characteristics up to an accuracy of a micrometer (µm).

With the laser triangulation method of the EyeScan AT, faulty balls of a Ball-Grid-Array can be detected. Thanks to the Scheimpflug-projection, the laser line stays focused and distortion-free on the surface of the component.

This also means that even for a high-speed application, the captured images have a high resolution, due to the big lens and short aperture time. And also the lens is of high-end quality and therefore no lens distortion correction has to be carried out.

Every single bump of the BGA is inspected for its size and shape up to a µm-accuracy.

And for solving this task, the EyeScan AT uses the most popular technology in 3D measurement – the laser line measurement (or lasertriangulation). The 3D-laser line projection is based on the principle of triangulation.

This means that the camera looks at a laser line, which is projected onto the component (in this case: the BGA) and calculates the height information from the laser line profile.

Thanks to the 20.000 profiles per second and due to the new blue laser, even the most complexe components and surfaces can be captured with a detailed resolution. The extremely fast scans are possible because of the even shorter aperture time.

Also with laser class 3 and the preprocessing of the captured data with the integrated FPGA, the EyeScan AT 3D is gaining on speed. Additionally the High Dynamic Range with threefold exposure allows to inspect bright and dark objects in the same scan, without loosing speed.

The image information are then sent to the EyeVision software and are then evaluated and further processed within the inspection program the customers have created by themselves.

This is very easy as the EyeVision software is programmed intuitively and is self-explanatory. With the drag-and-drop function there are no programming skills necessary for creating an inspection program.