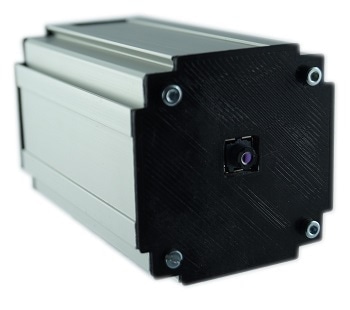

EVT presents the new EyeCheck Thermo 400. This is an intelligent thermal imaging camera with a microbolometer sensor for detecting infrared radiation between 8 and 14 µm.

The sensors are usually based on either amorphous silicon (a-Si) or vanadium oxide (VOx). EC Thermo 400 is based on the VOx sensor because of its excellent electrical conductivity. Even in changing ambient temperature the IR sensor is running steadily.

The array format of the EC Thermo 400 is 80 x 60 active pixels and the pixel size is 17 µm. The thermal sensitivity of the smart camera is < 50 mK. The EyeCheck Thermo 400 is equipped with the EyeVision image processing software which also contains commands for digital thermal image processing. And it also includes automatic thermal environment compensation, noise filters, non-uniformity correction and gain control.

The applications are manifold, but mainly for industrial inspection and process monitoring. Thermography can be used at all stages of production – from inspecting the quality of raw materials and processing of those raw materials to the inspection of the final product. Continuous temperature monitoring allows an early detection of defects. This saves money as bad raw materials and products can be separated directly.

Example industries are plastic, glass and steel processing. Applications include monitoring the cooling process after leaving the furnace, inspecting the material thickness by heating up the material, etc.

LWIR cameras can detect thermal radiation and do not need a source of illumination. Thermal radiation is visible through mist, rain and smoke. To detect objects at far distances, very low noise levels and a good temperature resolution are required.

The EyeCheck Thermo series is equipped with the EyeVision image processing software. Thus it is possible to evaluate the captured images directly on the camera. With the thermal imaging command set and the drag-and-drop function of the software, an inspection program can be created entirely without programming skills.