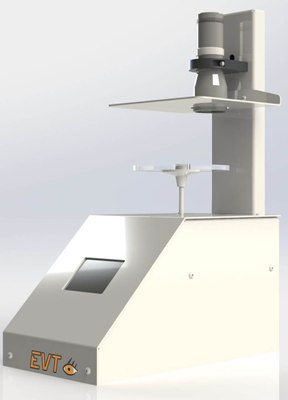

For applications with an increased demand in cleanliness, EVT has developed the Particle Inspector.

Particle Inspector

Particle Inspector

Applications ranging from production in microelectronics and precision engineering to life sciences and healthcare.

As all clean room products, the Particle Inspector is classified after ISO 14644 and are tested after VDI 2083. With the Particle Inspector the levels of deposited dust, microscopic fibers, microbes and other contaminants can be detected.

The Particle Inspector is a solution for measuring and collecting data about particle deposition at process-critical positions in the work environment. The deposition level and type of deposition is essential for effective surface cleanliness management.

The Particle Inspector has a resolution of 8 micron per pixel and a reproducibility of up to 95% for 20 particles. The measurement area reaches up to 2.700 mm² per witness plate and a measurement time of up to 60 seconds.

After the capture the images will digitized to transfer the data to a PC or Laptop. And then the data is analyzed and processed with the EyeVision software.

Per particle the Inspector captures: length and width (bounding box), the particle type (fiber, microbe, etc.), particle position on witness plate, etc. Additionally, the Particle Inspector captures actual samples of deposition particles to analyze and identify them. Measurement parameters are also P.A.C. (Percentage Area Covered) and P.D.C. (Percentage Deposition Class).

The Particle Inspector is perfectly suitable for the clean room and indispensable for the semiconductor industry.