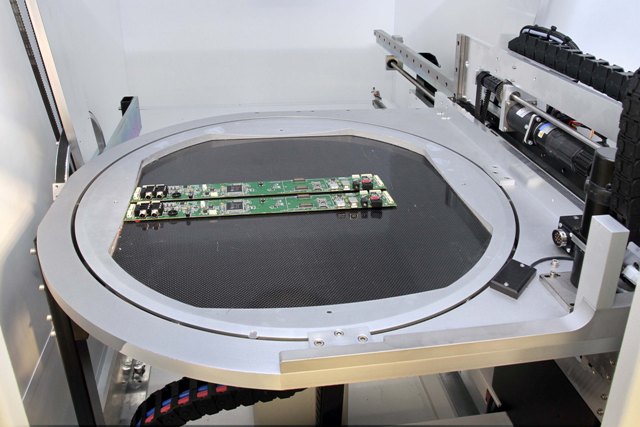

The Nikon Metrology XT V 160 X-ray machine installed at Newbury Electronics.

Newbury Electronics, one of the very few leading manufacturers of printed circuit board assemblies (PCBAs) in the UK, are investing in the sophisticated X-ray inspection system from Nikon Metrology – Nikon XT V160.

With the company having received large-volume PCBA contracts recently, such as the Bare Conductive contract for producing 15,000 PCBAs that will enable human interaction with its Electric Paint, using an X-ray machine was the only practical solution for the company for quality assurance of their PCBAs and this led to their investment in the XT V160 from Nikon Metrology.

Newbury Electronics’ managing director, Philip King (right) and Dave Roe, Senior Production Technician, with the XT V 160.

Nikon’s XT V160 offers a 400x400mm scan area, which is broad enough for most of the boards, and it also features control and analysis software. It is a high-end X-ray inspection system that comes with variable magnification, a powerful 160kV / 20W X-ray source, and a tilting flat panel detector.

The optional computed tomography inspection capability enhances the versatility of the Nikon system and re-constructs 3D images from 2D X-rays originating from an angular rotational scan, which allows rotation and slicing of the 3D image.

The system has an open-tube design, which will enable in-house replacement of the electron beam-producing filament every 6 to 9 months at low cost, unlike closed-tube designs where the tube needs replacement every one or two years at a high cost.

Other unique capabilities of the system are nanofocus X-ray spot source and sophisticated image processing.

A computer-controlled, electromagnetic lens maintains the focus of the electron beam and monitors overheating of the target while keeping the spot size at the nanoscale, even at high voltages.

The XT V160 enables BGA balls inspection assisted by single-axis control instead of three-axes manipulation.

The region of interest on the PCBA is identified and locked to keep it fixed regardless of varying rotation, tilt, or magnification.

The X-ray source in the system allows magnifications of about 2400x.

The board is viewable at angles of up to 75°, which enables clear views of through-holes and solder joints.

Newbury Electronics manufactured a backplane board for controlling hydrogen fuel cells in an electric motorbike under development by an R&D firm.

The board with 2,500 parts was completely inspected using the Nikon Metrology system. Technicians at Newbury Electronics claim that embracing the Nikon system has enabled zero-fault PCBA deliveries.

These PCBAs are for the Seaboard GRAND, an evolution of the piano invented by ROLI in London (www.roli.com), which allows per-note vibrato, volume change and glissando.

In addition to electronics inspection, the X-ray machine can also be used for X-ray and CT inspection of micro-electro-mechanical systems (used in smartphones), accelerometers, gyroscopes, and pressure sensors. It also helps in inspection of harnesses, small cables, plastic parts, switches, medical parts and LED lights.