Mar 20 2014

Samsung Electronics Co., Ltd., a world leader in advanced component solutions and LED component technology, said today that it has begun mass producing a value-added line-up of highly efficient lens-attached LED modules (LAMs), for use in office LED lighting applications that include linear and line lighting, cove lighting and troffers.

Samsung LED Lens-attached Module with Optic Technology (Graphic: Business Wire)

Samsung LED Lens-attached Module with Optic Technology (Graphic: Business Wire)

“With its LAM series, Samsung is rolling out leading-edge concepts in LED lighting design to the mass market and will continue to do so later this year and beyond,” said Bangwon Oh, senior vice president of strategic marketing team, LED Business, Samsung Electronics. “As LED’s penetration in the lighting industry increases, it is clear that enabling slimmer fixtures is an important area of market differentiation, an area where Samsung LAMs deliver the most efficient, homogeneous design solutions in LED lighting today.”

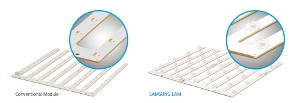

Samsung’s LAM series embraces a state-of-the-art concept in LED modules. The LAM solutions are created by attaching lenses on top of the LED packages in each module. The lenses add wide beam angles for their light sources using advanced optic technology, so that each LED package can brighten a space larger than that of conventional packages.

The new LAM series makes use of technology from Samsung LED packages for flat-TV backlight units (BLUs). In 2012, when LEDs became popular in BLUs for LCD TVs, Samsung created LED BLU modules combining lenses with LED packages to increase overall light output.

Using a Samsung LAM solution adds more design flexibility for a wide range of luminaires. Unlike fluorescent and incandescent lamps, conventional LED lighting features individual LED packages, each of which emits light. As a result, depending on the distance between the diffusion plate and the LED modules in the fixture, the spaces between packages on the module can appear as dark spots. To prevent this, the diffusion plate has to be placed further away from the module, which unfortunately increases the thickness of the fixture.

With the new Samsung LAM series using diffusion-improving optic technology, the diffusion plate can be placed much closer to the module – as close as 35 millimeters, a significantly smaller space than the 80 to 100 millimeters needed for conventional T5/T8 fluorescent tubes.

Samsung will showcase its new LAM series at the upcoming Light and Building trade fair being held in Frankfurt, Germany, March 31 - April 4, along with a wide variety of other LED component solutions.