VLC Photonics, a spin-off company from the Technical University of Valencia, has announced that it has made significant advances in optical integration. A unique “fabless” manufacturing model for fabricating optical chips has been developed.

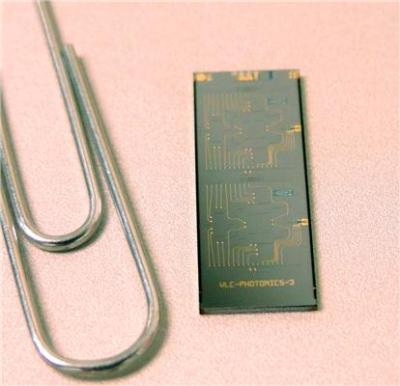

Example of photonic integrated circuit for optical telecommunications, fabricated by VLC Photonics in Indium Phosphide

Example of photonic integrated circuit for optical telecommunications, fabricated by VLC Photonics in Indium Phosphide

Development in microelectronic integration has been followed by optical integration, which has been miniaturizing large optical components such as photodetectors and lasers into chips. This has helped reduce the cost, size and weight of the components.

The “fabless” manufacturing model will enable foundries to provide chip fabrication services to design houses. The model encompasses efficiency, reliability and standardization, leading to decrease in cost of production. This also facilitates optical chip design houses, such as VLC Photonics, to integrate with other institutions and companies that require knowledge about optics and circuit design.

The CEO of VLC Photonics, Pascual Muñoz stated that vendors of optical components had developed fabrication processes by themselves in order to improve the manufacturing of devices such as lasers. The “fabless” manufacturing model will allow external users to build complex chips through generic building blocks. Using materials such as Indium Phosphide, hundreds of advanced optical devices can be embedded into a single chip.

Both private and public institutions have developed new foundries for these materials. Further, multiple shared-access integration platforms have also been developed. These allow sharing of wafer space between designers. Earlier, institutions had their own custom fabrication processes, but they were not able to deliver on a commercial scale.