Jun 19 2012

To meet the growing demands of Japanese automotive manufacturing, the Mechatronics Division of systems integrator Sumitomo Heavy Industries (SHI) is conducting applications-based trials using JK Lasers’ 1kW fiber laser (JK1000FL).

Initial results have revealed that the JK1000FL produces the necessary high speed, high quality welds for a range of industrial applications, including the welding of diesel injectors and airbag initiators.

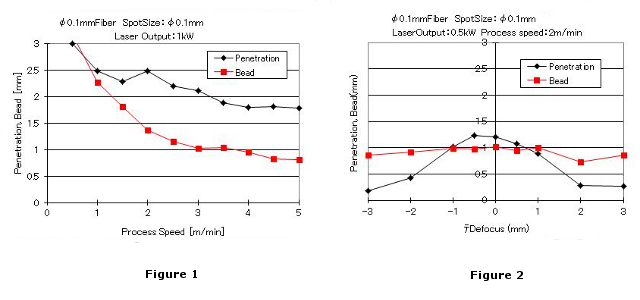

Compared to the 600µm spot size previously attainable using a CW Nd:YAG laser, a more focused 50µm – 200µm spot size can be achieved with the JK1000FL. This allows for deeper penetration or faster processing speeds. When keyhole welding stainless steel for example, the JK1000FL achieved nearly 2mm penetration at 3.5m per minute and 3mm penetration at 0.5m per minute (figure 1).

The exceptional beam quality of the JK1000FL also means it is tolerant to defocusing. As a result, processing parameters do not have to be altered to accommodate slight variations between the material and the nozzle tip or lens. SHI’s trials demonstrate that the penetration depth of the JK1000FL is insensitive to defocus in the range of ± 1mm (figure 2).

The ability to weld consistently while slightly defocused allows for manufacturing part variations and robotic welding arm path discrepancies. However, welding under these conditions - particularly when processing reflective materials such as copper and aluminium commonly used in automotive battery applications - can cause damaging back reflection. JK Lasers’ patented Plug-In, Pre-Aligned (PIPA) delivery fibres robustly protect the JK1000FL under these conditions.

Another important benefit of the JK1000FL is its energy efficiency. Consuming up to ten times less energy than Nd:YAG lasers of the same output power, fiber lasers are generating considerable interest in a country where electricity supplies are at an all-time low. Almost all of Japan’s 54 nuclear reactors – responsible for a third of the nation’s electricity – were shut down following last year’s devastating earthquake and tsunami.

Featuring a completely sealed optical design, fiber lasers eliminate the need for routine maintenance. With a mean time to failure (MTTF) of over 300,000 hours, the diode laser pump sources used in JK Fiber Lasers are extremely reliable and help deliver wall-plug efficiencies of over 25% as part of an optimised laser design.

The Mechatronics Division of SHI has worked closely with JK Lasers for over two decades, integrating the laser manufacturer’s comprehensive range of Nd:YAG and fiber lasers into its machines to create high quality production technology.