Jenoptik will exhibit microoptics-based homogenizers in CaF2, at SEMICON West 2012 at Moscone Center, San Francisco, from July 10th to 12th.

Jenoptik demonstrates highly flexible manufacturing capabilities for DUV microoptics

Jenoptik demonstrates highly flexible manufacturing capabilities for DUV microoptics

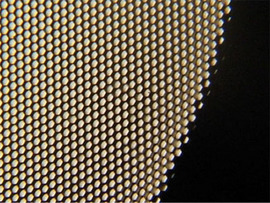

Optical systems of inspection equipment, semiconductor and flat panel display manufacturing use homogenizers such as diffractive optical elements (DOEs) or microlens arrays. Homogenizers are a major part of illumination systems and promote distribution of light over a particular area within the optical beam path’s specific plane. The related optical and micro-optical components are expected to comply with requirements for an extended life and meet the optimum transmission for short wavelength high energy laser radiation. CaF2 features a higher damage threshold than other optical materials. It ensures extensive stability of optical performance.

During this year’s SEMICON West, Jenoptik will present the company’s highly versatile manufacturing features for micro-optical structures in CaF2, highlighting its wavelength rages of 193-266 nm. In addition, the company will also demonstrate various other CaF2 homogenizer arrangements. The advanced micro-structuring process integrated with grayscale technology and an innovative wafer level etching process enables Jenoptik to design and develop customized hybrid, refractive, and diffractive structures with asymmetric radii and shapes. This fabrication process features the generation of free geometries, in addition to the reproducibility and precision involved in microstructuring process. A variety of beam distribution patterns are created leading to new technical solutions that entails the optimization of system performance of semiconductor manufacturing equipment.

Furthermore, standard manufacturing processes are being offered for a variety of optical materials including Chalcogenide, SiO2, GaAs, Al2O3, GaP, ZnS, ZnSe, Ge, and more. The quality of optical product properties can be ensured through qualified testing at operating wavelength.