A prototype system has been launched by a research team from Food Processing Technology Division at the Georgia Tech Research Institute (GTRI), using smart imaging technology and a robotic cutting and deboning arm to remove bones from poultry products e.g. chicken.

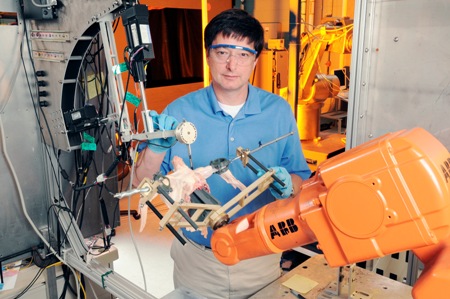

Gary McMurray with robotic prototype system to debone the chicken

Gary McMurray with robotic prototype system to debone the chicken

The arm includes a three-dimensional vision system, which can be used to determine the exact cutting position in a particular bird. It ensures accurate cuts, thereby minimizing the risk of bone fragments in the completed product. State of Georgia has funded this research on deboning technique via the Agricultural Technology Research Program at GTRI.

Michael Matthews, a research engineer at GTRI, illustrated that prior to cut, the chicken is placed in front of the 3D vision system, which measures several location points on the outside of the chicken. Custom algorithms use these measured location points as inputs to calculate the positions of the internal parts such as ligaments and bones, and to define the exact cut with the estimated positions. The developed prototype system performs cutting close to the bones so that the breast meat yield is maximized and food safety is assured by eliminating the creation of bone chips.

To perform simple planar cuts, the system employs a fixed two-degree-of-freedom cutting robot. The chicken is placed on a 6-degree-of-freedom robot arm, which ensures that the cutting robot and the chicken can be placed at any desired position. The robotic arm locates the chicken under the 3D vision system and moves the chicken relative to the cutting robot.

Ai-Ping Hu, a research engineer at GTRI, stated that a force-feedback algorithm is used to identify the transition from meat to bone. This helps to move the knife along the bone surface with a constant force. Hu added that a force sensor attached to the cutting knife’s handle is used to identify the imminent contact of the knife with the bone. This helps the prototype system to allow the cutting arm to perform an appropriate diversion route around the bone, thereby avoiding a straight cut through the bone.