Phoseon Technology supplies latest UV LED line of products. The new high-performance UV LED Pinning lamp will allow rapid, high-quality digital inkjet pinning applications. The FireEdge FE200 delivers increased inkjet print head dimensions and therefore widely deployed in the booming inkjet markets.

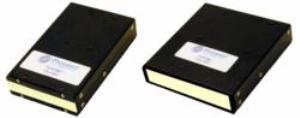

FIreEdge 75x10mm and 110x10mm UV LED Pinning Lamps

FIreEdge 75x10mm and 110x10mm UV LED Pinning Lamps

IMI Europe’s Mike Willis said that the pinning process is being used by printer manufacturers to ‘freeze’ the ink drops prior to full-cure or overlaying procedures. In addition, the process helps control matte or gloss surface finishing attributes.

According to the President and CEO of Phoseon Technology, Bill Cortelyou, in response to customers’ demands regarding high-speed and higher-quality, this new product design has been launched. Both efficiency and speed have been incorporated with Pinning. The inkjet print head interference can be eliminated by using the FE200 top air intake and exhaust. The units can be prepared to serve various print width applications.

Cortelyou added that the optional Angle Reduction Technology, which is patent-pending, cuts down the UV light’s angular spread by 67%.

The three major advantages of the FireEdge FE200 UV LED lamp include high scalability for inkjet printer manufacturers through its variable print widths, and air intake or exhaust from top of the unit. It provides simple integration through integrated control, small form factor related to print head dimensions, daisy chain capability, and a sole connector for data and power. It ensures strong control with instant on-off capabilities, allowing variable intensity from 10% to 100%.

With these key industrial benefits, the eco-friendly, affordable UV LED curing from Phoseon is a unique solution with integrated control, performance, and real-world reliability to meet the challenges in curing environments.

Phoseon will showcase both the products at the approaching Drupa Trade Fair in Dusseldorf, Germany.