Pinpoint Laser Systems released a new 4D laser-based Microgage System employed for precise measurement in examining and rectifying machinery alignment complexities.

New 4-Axis Microgage Laser-Based Solution for Alignment of Moving Machinery Announced by Pinpoint Laser Systems

New 4-Axis Microgage Laser-Based Solution for Alignment of Moving Machinery Announced by Pinpoint Laser Systems

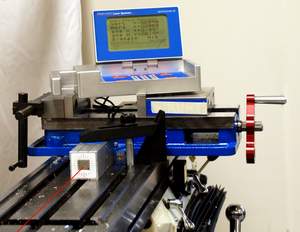

The President of Pinpoint Laser Systems, Mory Creighton says that the new Laser Microgage 4D comprises a receiver that is capable of functioning over 100 ft and provides accurate measurement of 0.0005 in and 0.002º. It is best suited for turning centers, aligning lathes, spindles, and also rams and pistons, moving linear slides, moving mechanical sub-assemblies, and injection molding machinery.

Mr. Creighton further stated that the Laser Microgage 4D system and receiver facilitates manufacturers and engineers with direct control over accurate measurement and alignment, which can be used to observe and stabilize the company’s own production equipment and machinery. Its significant applications include reducing downtime and unexpected costs and relying on external service bureaus.

The operation of Laser 4D Microgage is uncomplicated, wherein a focused, narrow, red laser beam generates a measuring reference line which settles on an internal detector, facilitating the receiver to measure and determine the angular alignment or position of a machine or sub-assembly analogous to this laser reference beam.

An extensive array of simplified products that are integrated with electronics, optics, and lasers has been provided by Pinpoint Since 1992. In addition, it offers robust mechanical features for complex measuring and routine alignment tasks.

This measuring equipment from Pinpoint has its wide application in the aerospace industry, paper and textile mills, machine shops, extrusion plants, shipbuilding facilities, and electronic assembly facilities. In association with producers, the company intends to develop particularly designed alignment systems for medical scanning devices, robotic applications, and various other applications.