Pinpoint Laser Systems, provider of laser measuring instruments, announced that it has launched a new Microgage Receiver that offers alignment details for correcting and evaluating the machine alignment problems.

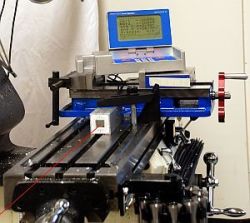

Microgage Receiver System

Microgage Receiver System

The four-axis Microgage Receiver measures the two linear axes X and Y. The linear axes display the level of machinery alignment. The Microgage Receiver also measures yaw and pitch, the two angular components. The angular components display the parallelism problems.

The Microgage Receiver is ideal for moving mechanical sub-assemblies, injection molding machinery, pistons and rams, and linear slides. It is also suitable for aligning spindles, turning centers, and lathes. The receiver’s digital display offers accurate angular and linear readings.

A thin laser beam offers a measuring reference line and the receiver measures the laser line landing on an internal detector. The Microgage Receiver then decides on the position of a sub-assembly or the machine relative to the laser reference beam.

The receiver operates at distances of over 100 ft and delivers a measuring accuracy of 0.005º and 0.0005”. It is suitable for adverse industrial alignment applications. The Laser Microgage device, together with the 4D Microgage Receiver offers accurate alignment and measuring capability for manufacturing personnel and plant engineers.