Researchers are involved in creating new technologies that coalesce laser and electric fields to segregate liquids and small particles such as virus, bacteria, and DNA, enabling a wide range of industrial application from food safety to drug production.

A method referred to as hybrid optoelectric manipulation in microfluidics is an efficient tool for applications such as testing food and water, crime-scene forensics, medical diagnostics, and pharmaceutical manufacturing.

New technology that combines laser and electric fields to manipulate fluids and tiny particles

New technology that combines laser and electric fields to manipulate fluids and tiny particles

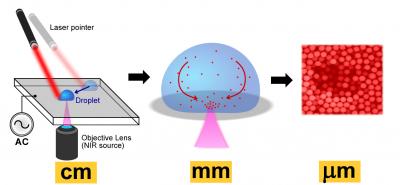

Firstly, the technology uses a red laser to place a droplet on a platform. Next, a beam of infrared laser is directed to heat the droplets followed by an electric field that causes the heated liquid to rotate in a microfluidic vortex. The vortex is used to separate specific kind of particles in the rotating fluid, similar to a micro centrifuge. Concentrations of the particles are identical to the location, size, and shape of the infrared laser pattern.

System based on hybrid optoelectric approach can be created to accurately identify, manipulate and monitor specific kinds of bacteria and bacterial strains, causing heavy metals to be less toxic. This technology is useful in pharmaceutical industry because some drugs are produced from solid particles suspended in liquid medium. The technology may act as a tool for nanomanufacturing by gathering suspended particles, called colloids.

Steven T. Wereley, a mechanical engineering professor of Purdue University, stated the new technologies can produce analytical devices and innovative sensors for lab-on-a-chip applications.

Aloke Kumar, staff member at Oak Ridge National Laboratory, stated that combination of these techniques not only allows manipulation of larger objects such as droplets, but also for small molecules like DNA present inside the droplets.