Jul 9 2010

Ultrafast laser technology developer, Raydiance, has demonstrated its capability to perform machine precise, micron-resolution features in materials that are difficult to process, platinum and gold. With the help of Raydiance’s Smart Light 50 femtosecond pulse laser, the company’s engineers obtained the results. The Smart Light 50 laser was used in combination with a Rofin StarCut Tube workstation.

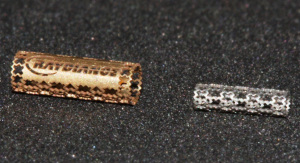

Gold and platinum stents machined with the Raydiance ultrafast laser platform

Gold and platinum stents machined with the Raydiance ultrafast laser platform

Platinum and gold have the characteristics of high electrical conductivity, radiopacity, and resistance to corrosion. Due to these characteristics, they are extensively used in medical devices such as guide wires used in cardiovascular procedures, cardiovascular stents, and heart rhythm leads. In the guide wires and cardiovascular stents applications, these metals are utilized as X-ray markers to help surgeons view the devices better while performing medical procedures.

The pulse laser ablates by non-linear optical breakdown process that allows the micron-resolution ablation of any type of material. During this breakdown process, heat is not transferred to the part that is being machined.

Raydiance President, Scott Davison, stated that medical device producers find it difficult to machine precise features in these metals. The conventional tools such as electron discharge machining, and nanosecond lasers produce thermal effects and burrs that require costly post-processing. Raydiance’s new platform offers an athermal solution for this manufacturing problem, Davison said.