In optics and laser technology, achieving precise control over the shape and characteristics of a beam is important for several applications. This article discusses complex beam shaping, its applications and recent relevant studies.

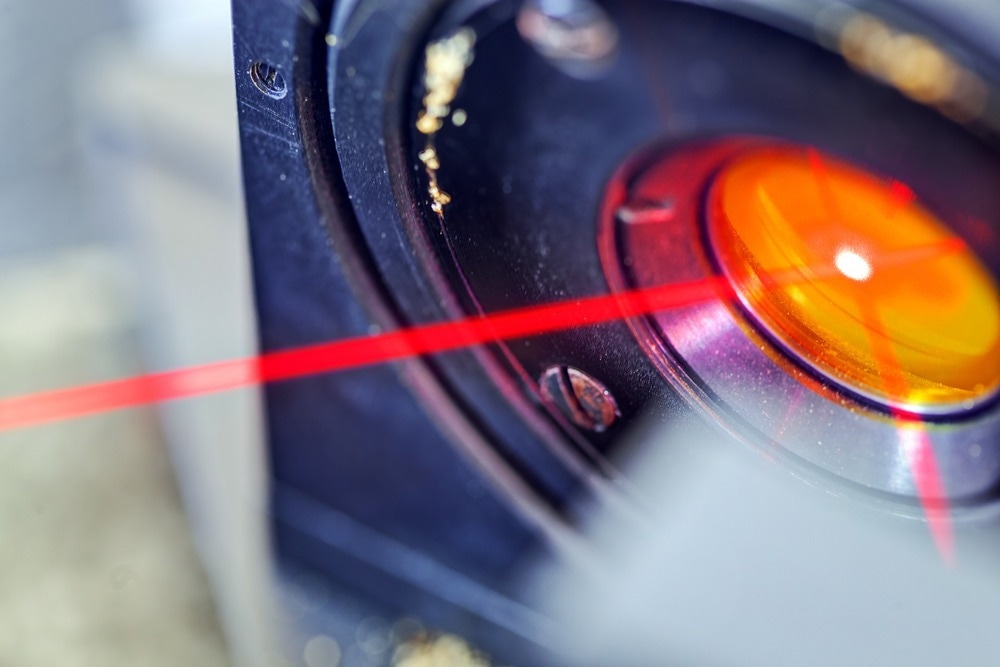

Image Credit: Vladimir Nenezic/Shutterstock.com

What is Beam Shaping?

Beam shaping is often necessary to optimize laser systems for diverse applications like material processing, medical treatments, communication, and scientific research. Beam shaping means tailoring the properties of a laser beam to meet specific requirements by controlling parameters like beam size, divergence, and intensity distribution.

For instance, controlling the size and divergence of a laser beam by using lenses, mirrors, and optical elements that alter the spatial characteristics of the beam is essential for directing the energy to the desired location with precision. Adaptive optics systems can dynamically adjust the beam parameters in real-time to compensate for environmental factors and enhance performance.

How Complex Beam Shaping Is Achieved?

Complex beam shaping involves manipulating light or other electromagnetic waves to achieve desired spatial intensity distributions by utilizing advanced optics, such as diffractive optical elements or spatial light modulators, to mold the beam's profile. Achieving optimal shaping requires intricate design algorithms and sophisticated optical components, demanding expertise in both theoretical and practical aspects of wavefront engineering.

For instance, SLMs are sophisticated devices for dynamic control of the phase and amplitude of light waves across a beam, enabling real-time beam shaping for applications where rapid changes in the beam profile are necessary, such as in optical communication. Similarly, the holographic technique is particularly useful for applications requiring complex beam profiles or tailored focal patterns.

Recent Studies

Innovative Meta-Q-Plate for Beam Shaping

In a 2016 study, researchers introduced a groundbreaking development in optical beam shaping through the concept of meta-q-plate. The meta-q-plate, featuring arbitrarily space-variant optical axes, was demonstrated using liquid crystal photoalignment and a dynamic micro-lithography system.

This innovative approach allows the fabrication of meta-q-plates with multiple-, azimuthally/radially variant topological charges and initial azimuthal angles. As a result, complex beams with elliptical, asymmetrical, multi-ringed, and hurricane transverse profiles are generated, enabling unprecedented flexibility in manipulating optical vortex.

This development significantly enhances the capability of beam shaping, providing a novel method to control polarization and spatial degrees of freedom of light in a point-to-point manner. The meta-q-plate design opens new avenues for advancements in optical manipulations, OAM-based informatics, quantum optics, and related fields.

Optimizing Complex Beam Shaping with Digital Lens

In a recent study, researchers addressed the persistent challenge of zero-order diffraction in beam shaping using pixelated spatial light modulators (SLMs). They introduced an innovative approach to achieve zero-order-free beam shaping by incorporating an asymmetric triangle reflector, a digital blazed grating, and a digital lens into the phase hologram on the SLM.

By enhancing existing complex-amplitude coding algorithms with the addition of a digital lens phase, the researchers successfully generated complex beams without the interference of zero-order diffraction.

The study focused on optimizing beam shaping configurations, considering factors like small-angle illumination and vertical output angles. Simulations and experimental validations demonstrated the effectiveness of the proposed method, offering a promising solution for complex beam shaping, particularly in applications involving high-power lasers.

Overcoming Challenges in Metal Additive Manufacturing

A 2022 study addressed challenges in laser powder bed fusion-enabled metal additive manufacturing (AM) by employing advanced beam shaping techniques. Conventional Gaussian beams often lead to poor mechanical properties due to issues like large thermal gradients and melt pool instabilities.

The study introduces laser beams shaped in amplitude, phase, and polarization to control optothermal profiles on the powder bed. Specifically, Bessel beams were used, resulting in improved properties such as reduced porosity, increased part density, and lower surface roughness compared to Gaussian beams. The Bessel beams exhibited larger aspect ratios in melt pools, reduced sensitivity to focal plane positioning, stabilized melt pool turbulence, and decreased spatter.

The approach demonstrated enhanced mechanical and morphological properties in 3D-printed structures, offering a promising solution to achieve complex beam shaping for improved metal additive manufacturing.

Applications of Complex Beam Shaping

Complex beam shaping has many applications across several fields, including material processing, biomedical, communication, and sensing. For instance, in medical treatments, such as laser surgery and therapeutic applications, complex beam shaping helps to target tissues precisely, minimizing damage to surrounding areas and improving the overall effectiveness of medical procedures.

Similarly, complex beam shaping ensures efficient energy delivery, minimizing thermal damage in laser material processing operations like cutting, welding, and engraving. In optical communication systems, complex beam shaping optimizes signal transmission and reception. For instance, in lidar and other sensing applications, tailored laser beams enhance the accuracy and resolution of distance and depth measurements.

Conclusion

In conclusion, achieving complex beam shaping is crucial for optimizing laser systems across diverse applications. The ability to control beam characteristics precisely through innovative technologies like meta-q-plates and digital lenses opens new possibilities in optics. Recent studies such as overcoming zero-order diffraction challenges and improving metal additive manufacturing with Bessel beams highlight the importance of complex beam shaping and help with enhanced performance, reduced damage, and improved accuracy across various domains.

More from AZoOptics: How is Machine Learning Leveraged in Photonic Design?

References and Further Reading

Ji, W., Lee, C. H., Chen, P., Hu, W., Ming, Y., Zhang, L., ... & Lu, Y. Q. (2016). Meta-q-plate for complex beam shaping. Scientific reports. https://doi.org/10.1038/srep25528

Liang, Y., Yun, X., He, M., Wang, Z., Wang, S., & Lei, M. (2022). Zero-order-free complex beam shaping. Optics and Lasers in Engineering. https://doi.org/10.1016/j.optlaseng.2022.107048

Schmidt, S., Thiele, S., Toulouse, A., Bösel, C., Tiess, T., Herkommer, A., ... & Giessen, H. (2020). Tailored micro-optical freeform holograms for integrated complex beam shaping. Optica. https://doi.org/10.1364/OPTICA.395177

Sivarajah, Ilamaran. (2023, May 15). A Guide to Laser Beam Shaping Techniques. AZoOptics. Retrieved on January 18, 2024 from https://www.azooptics.com/Article.aspx?ArticleID=2432

Tumkur, T. U., Guss, G., Roehling, J. D., Khairallah, S. A., & Matthews, M. J. (2022). Metal Additive Manufacturing using complex beam shaping. Procedia. https://doi.org/10.1016/j.procir.2022.08.128

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.