Ultrafast lasers, such as picosecond and femtosecond lasers, are extensively utilized in the fields of materials science and engineering. The recent progress in amplification systems has led to considerable advancements in the field of ultrafast lasers, which is beneficial to various industries, especially the materials sciences. Ultrafast lasers can alter various materials, and the exceptional resolution of ultrafast lasers, along with their short bursts, make them the best choice for precise target-specific applications.

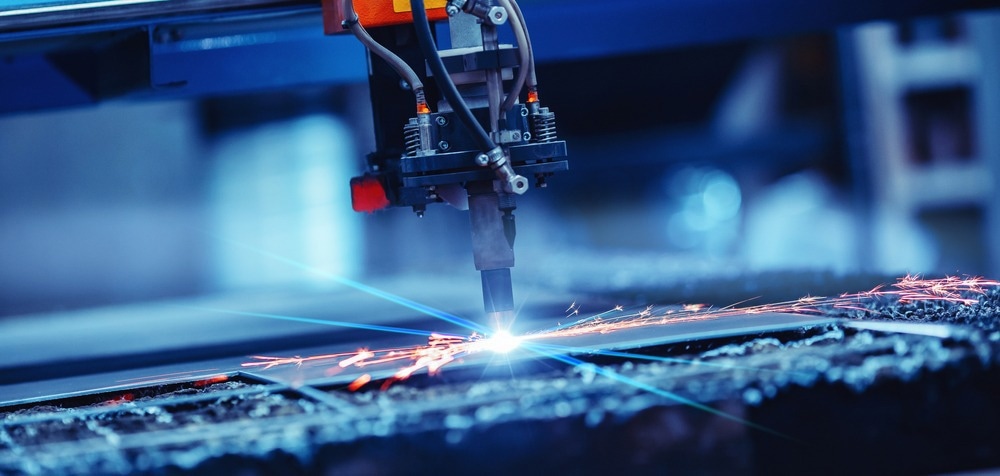

Image Credit: Parilov/Shutterstock.com

Ultrafast Lasers for Nanoscale Structuring of Materials

Recently, there has been a lot of interest in the research and commercial materials science sector towards the utilization of ultrafast lasers for the production of nanoscale features. This is mainly due to the worldwide industrial focus on miniaturization, with novel manufacturing techniques and tools like ultrafast lasers enabling compactness.

A recent article in Nanophotonics states that the most advanced approach used industrially to shape any material, especially solids, is done by directing high-energy ultrafast lasers onto its surface with sufficient intensity to stimulate and remove material.

In addition to direct ablation processes, when surfaces are excited, another kind of structuring phenomenon utilizing ultrafast lasers emerges. This entails a transformation of surface topography into a regular pattern with sub-wavelength periodicities, known as ultrafast laser-induced periodic surface structures.

The initial concept crucial for bulk nanostructuring involves what is called a "microexplosion." This concept entails stimulating high-density plasmas with ultrafast lasers, which results in the development of substantial electronic pressure, shockwaves, and rarefactions at multi-MBar levels. Nanoscale structures are achieved through the precise focusing of ultrafast lasers.

The application areas for nanostructures produced by ultrafast lasers are extensive and varied. They yield high-performance functions in optics, mechanics, and biology, particularly when the structuring occurs within the range of optical wavelengths. This is attributable to properties related to surface topography, specific surface characteristics, or feature size.

Ultrafast Lasers: The Only Effective Method for Welding of Ceramics

Modern manufacturing heavily relies on welding, but achieving dependable ceramic welding through traditional methods remains an unattainable goal. The same exceptional high-temperature resistance that renders engineered ceramics indispensable for numerous challenging applications also presents formidable challenges when it comes to joining ceramics.

The advantages of ultrafast lasers for welding ceramics have been highlighted in a recent article published in Science. The precise energy delivery provided by ultrafast lasers plays a pivotal role in additive manufacturing and holds the potential to be highly effective in ceramic joining. Notably, there have been successful instances of using ultrafast lasers to join various types of glasses.

It is important to note that some of the glasses successfully welded with ultrafast lasers, like borosilicate, exhibit lower fracture toughness and thermal shock resistance compared to typical engineered ceramics such as stabilized zirconia and alumina. Accomplishing successful ultrafast laser joining in ceramics hinges on the capacity to focus the laser within the material, thereby triggering nonlinear and multi-photon absorption processes that result in localized absorption and melting.

In a recent article, a novel ultrafast pulsed laser welding method was introduced. This technique focused light on interfaces within ceramics, creating an optical interaction volume that stimulated nonlinear absorption processes, resulting in localized melting rather than ablation. The critical factor in the study was the interplay between linear and nonlinear optical characteristics, along with the efficient coupling of laser energy with the material.

The ceramic assemblies produced using this laser welding approach maintained high vacuum conditions and exhibited shear strengths comparable to metal-to-ceramic diffusion bonds. Laser welding can now integrate ceramics into devices intended for demanding environments, as well as in packages for optoelectronics and electronics that require transparency in the visible-to-radio frequency spectrum.

Ultrafast lasers find particular versatility in welding transparent ceramics because they can be focused through the material. This allows for the joining of more intricate geometries across multiple interaction zones, thereby expanding the potential weld volumes.

Ultrafast Lasers for Processing of Materials

The utilization of ultrafast lasers for materials processing has undergone substantial growth in the past decade, and the scientific, technological, and industrial applications are becoming increasingly evident.

In the domain of ultrafast lasers for manufacturing, optical energy is harnessed from tightly focused femtosecond or picosecond ultrafast lasers via pulses and directed to highly specific locations within materials. This is achieved through two- or multi-photon excitation, occurring on a timescale much faster than the exchange of thermal energy between photo-excited electrons and lattice ions.

The utmost precision in managing the photoionization of ultrafast lasers and thermal processes has been realized, enabling the localized photo-modification of regions smaller than 100 nanometers.

As per the article published in Light: Science and Applications, the utilization of ultrafast lasers, which operate at either 10 or 1 μm wavelengths in continuous wave (CW) or pulsed mode, are already making significant contributions to the automotive, construction, and marking sectors.

For instance, ultrafast lasers like Femtosecond (fs) lasers are instrumental in applications demanding high precision, especially when it involves structuring both the surface and bulk of brittle and hard transparent materials. Moreover, when the need arises to intricately structure composite and layered materials in a complex 3D manner, ultrafast lasers such as fs-laser structuring prove to be highly effective.

Challenges Faced During the Process of Ultrafast Laser Processing

The processing and functionalizing of materials using ultrafast lasers is a remarkable process; however, certain challenges need to be overcome, as specified by a recent article in Advanced Optical Technologies.

Many modern ultrafast lasers only have an ablation depth of only a few hundred nm for a single burst. This signifies that a significantly high number of ultrafast laser pulses are needed to be directed on a single area to ablate the material. Additionally, the maximum efficiency of material processing by Gaussian ultrafast lasers in recent studies comes out to be around 12%. This efficiency percentage raises a lot of questions about the industrial utilization of Gaussian ultrafast lasers.

The processing optical system, an integral part of ultrafast lasers, can induce nonlinear effects that alter the characteristics of the emitted pulses. This can affect parameters like the pulse duration and the spectrum of the ultrafast lasers. In extreme situations, the intense energy within the optical components may lead to damage to the material being targeted with the ultrafast lasers.

There are numerous applications of ultrafast lasers in materials sciences. With the current advancements in artificial intelligence technology and the incorporation of big data analysis, it is possible to establish a dependable correlation between the process, structure, and performance in the applications of ultrafast laser material processing within materials sciences.

This approach is expected to streamline the use of ultrafast lasers for additive manufacturing of materials and enhance the precision of computations, offering an effective means of achieving various commercial goals.

More from AZoOptics: Nonlinear Optical Phenomena in Photonic Crystals

References and Further Reading

Laserlab Europe, (2023). Lasers for Materials Science. [Online]

Available at: https://www.laserlab-europe.eu/research/lasers-for-material-science

Stoian, R., & Colombier, J. P. (2020). Advances in ultrafast laser structuring of materials at the nanoscale. Nanophotonics, 9(16), 4665-4688. Available at: https://doi.org/10.1515/nanoph-2020-0310

Penilla, E. et. al. (2019). Ultrafast laser welding of ceramics. Science, 365(6455), 803-808. Available at: https://doi.org/10.1126/science.aaw6699

Malinauskas, M. et al. (2016) Ultrafast laser processing of materials: from science to industry. Light Sci Appl 5, e16133. Available at: https://doi.org/10.1038/lsa.2016.133

Weber, R. et. al. (2021). The challenges of productive materials processing with ultrafast lasers. Advanced Optical Technologies, 10(4-5), 239-245. Available at: https://doi.org/10.1515/aot-2021-003

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.