With advanced resolutions reaching sub-angstrom levels, electron microscopy provides direct visualizations of catalyst particles, support structures, and pores that complement spectroscopic and diffraction methods. When integrated with elemental analysis techniques, a comprehensive picture of catalytic systems can be built up from the microscopic level.

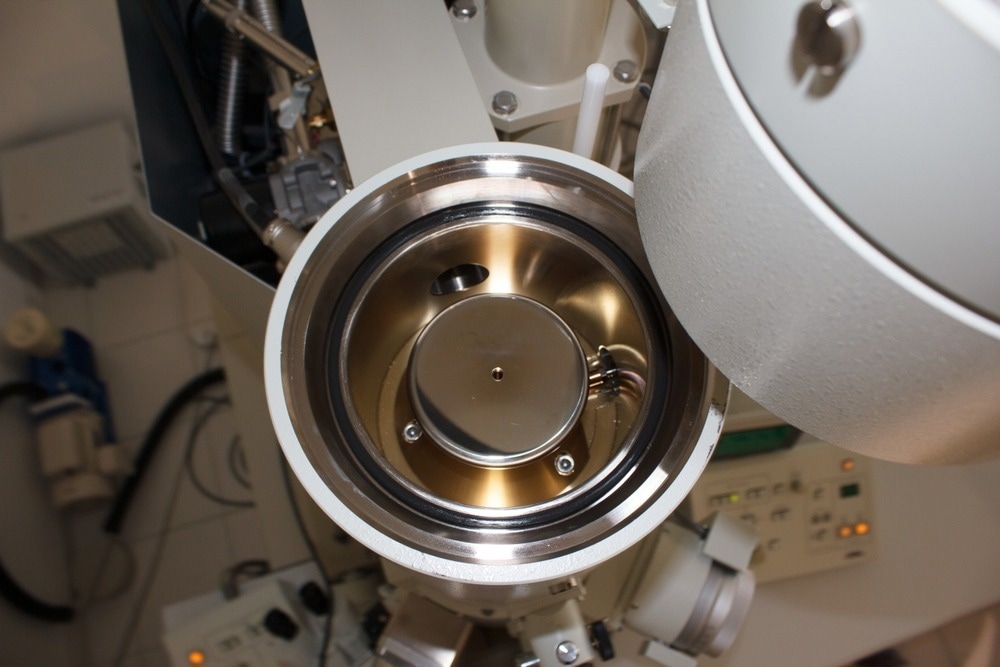

Image Credit: Pvince73/Shutterstock.com

Significance of Characterizing Catalysts

Catalysts are indispensable materials in the chemical, petrochemical, and life science industries, involved in over 90% of chemical manufacturing processes. They work by modifying the rates of desired chemical reactions, allowing important industrial processes to occur efficiently under optimized conditions. The global catalyst market is enormous, and despite the relatively low cost of catalyst materials, their influence on catalytic reactions significantly contributes to overall revenue.

Despite the long history of using catalysts in industrial applications stretching over 150 years, the science of how catalysts function remains complex. Precisely describing the interactions of catalysts and reactants at multiple length scales from macro to nano presents an ongoing challenge.

Gaining fundamental knowledge of catalyst composition, atomic-level surface structure, porosity, and other physical properties is key to understanding the catalytic mechanisms, improving existing catalysts, and rationally designing new ones.

Various characterization techniques, such as X-ray photoelectron, Raman, ultraviolet, and atomic emission, are only limited to surface analysis. However, recent advances in electron microscopy and related microanalytical methods have expanded the scope to collect localized structural and chemical data from catalysts, facilitating the understanding of microstructure-catalytic property relationships essential for catalyst design.

How Are Electron Microscopy Techniques Used to Characterize Catalysts?

Particle Characterization

Transmission electron microscopy (TEM) uses a focused beam of high-energy electrons transmitted through an ultra-thin sample to image objects down to the nanometer scale. In catalyst characterization, TEM is applied to directly visualize the size, shape, distribution, and location of catalyst particles across the support framework.

TEM provides particle morphology and distribution information for supported metal catalysts based on nanoparticles of platinum, palladium, gold and other metals dispersed on oxide supports (e.g., Al2O3, SiO2).

Atomic-level microscopy is not possible with traditional TEM, but crystal lattice fringes can be resolved for particles above 2-3 nm sizes. This permits the identification of catalyst particle composition and exposed crystal facets.

TEM is also employed to visualize porous support structures such as zeolites and mesoporous silicas, allowing the examination of pore sizes, particle aggregation, and the deposition of active catalyst phases across micron-scale fields of view. It enables direct imaging of graphene sheet curvature, stacking, and catalyst particle infiltration for non-periodic support structures like activated carbons.

A main benefit of TEM is the direct visualization of catalyst structural features like particle location, support adherence, and contaminant phases. However, image analysis must be quantitative to derive statistically meaningful metrics for catalyst design.

Atomic-Scale Insights

High-resolution TEM (HRTEM) provides atomic-scale lattice fringe imaging, enabling phase identification of individual nanoparticles as small as 1-2 nm. HRTEM reveals surface faceting and defects like stacking faults, twins, and dislocations within nanocrystals. Such atomic-level insights into nanoparticle structures are invaluable, as surface structures and defects critically control catalytic performance.

Topography of Catalyst Support Structures

Scanning electron microscopy (SEM) complements TEM, providing three-dimensional imaging and topological information. While TEM forms projections by transmitting electrons through thin samples, scanning electron microscopy (SEM) images surface morphologies via electron scattering.

SEM is especially useful for examining porous non-crystalline catalyst supports like silica and activated carbons. The wide field of view and depth of focus in SEM enables rapid assessment of particle distributions across non-uniform catalyst surfaces.

Combinational Microscopy Techniques

Scanning transmission electron microscopy (STEM) combines aspects of both TEM and SEM. Instead of a broad parallel illumination, the STEM electron beam is focused on a sub-nanometer spot scanned over the sample. It enables nano-diffraction for crystal symmetry analysis and provides precise 3D structure determination for analyzing complex mixed-phase catalysts.

Electron microscopy techniques are often coupled with spectroscopic capabilities like energy-dispersive X-ray spectroscopy (EDS) and electron energy loss spectroscopy (EELS). These provide elemental identification and mapping at the nanoscale, elucidating chemical compositions and spatial distributions of catalyst components.

Recent Research and Development

Unveiling Nickel's Catalytic Potential with Liquid-Phase Electron Microscopy

A study published in Nano Research has employed liquid-phase electron microscopy to enhance our understanding of nickel's crystallization process at the atomic level. Nickel, an abundant and cost-effective metal, has garnered interest as a catalyst for various industrial processes.

However, its catalytic efficiency falls short of precious metals-containing catalysts. To address this limitation, researchers sought to uncover the fundamental mechanisms underlying nickel's crystallization and structure formation, particularly in its nanocrystalline state.

Researchers created a supersaturated nickel solution, causing any excess nickel to precipitate as solid crystals through crystallization, and then employed liquid-phase electron microscopy to observe and directly visualize the nucleation processes. This provided insights into the dynamic stages of amorphous-phase-mediated crystallization of hexagonal nickel nanoparticles and their facet development.

These findings hold promise for the future design of hexagonal nickel materials and catalysts, improving nickel's catalytic capabilities.

In Situ TEM Reveals Mechanical Properties of MoS2 Photocatalyst Nanoribbons

A recent study published in Advanced Science used in situ TEM to investigate the mechanical properties of single-layer molybdenum disulfide (MoS2) nanoribbons with armchair edges. MoS2 composites are promising photocatalysts for photocatalytic degradation of environmental pollutants.

The study introduced a novel micromechanical measurement technique involving a quartz-based length extension resonator within an in situ TEM holder. This approach allowed for precise estimation of the nanoribbons' equivalent spring constant and Young's modulus by monitoring changes in the quartz resonator's resonance frequency and analyzing TEM images for nanoribbon dimensions.

The study found that Young's modulus increased as the nanoribbon width decreased below 3 nanometers, suggesting implications for designing nanoscale, ultra-thin catalysts, particularly in photocatalysis applications.

Multimodal Electron Microscopy Characterization of 3D Hierarchical Nanocatalysts

In a study published in Science Advances, UNSW Sydney researchers used electron microscopy techniques to examine and characterize 3D nanocatalysts created through a novel bottom-up synthesis method. These nanocatalysts demonstrated significant advantages for electrocatalysis, including their nanoscale size for increased surface area, direct metal connections for efficient electron transfer, and chemically adaptable surfaces for versatile catalytic uses.

The study involved a multistep process for growing these 3D nanostructures, with each step's products analyzed and characterized using STEM in combination with energy-dispersive x-ray spectroscopy (EDX) and high-angle annular dark-field (HAADF)–STEM.

TEM aided in visualizing the growth process, highlighting the significance of selecting face-centered cubic (fcc)-Au as the core and hexagonal close-packed (hcp)-Ni as the branch material in forming a hierarchical structure. Additionally, HAADF-STEM imaging allowed for a detailed examination of the 3D morphology of the nanostructures, enhancing our understanding of their uniformity and spatial arrangement.

Additionally, TEM analysis confirmed that the morphology of the 3D nanostructures remained unaltered after chronopotentiometry, providing solid evidence for the structural stability of these supports. This highlights the effectiveness of using 3D nanostructures as electrocatalytic supports.

Future Outlooks

Electron microscopy has become an essential approach in the toolbox of techniques to characterize heterogeneous catalyst materials across length scales from single atoms to microns.

Ongoing advances in electron microscopy resolution, chemical analysis, and in situ techniques will drive further discoveries of how nanostructure influences catalysis. By leveraging electron microscopy's ability to visualize catalyst components down to the atomic scale under working conditions, transformative knowledge can be gained to design the next generation of optimized catalysts.

More from AZoOptics: Looking Closer at the Global Electron Microscopy Market

References and Further Reading

Gloag, L., Poerwoprajitno, A. R., Cheong, S., Ramadhan, Z. R., Adschiri, T., Gooding, J. J., & Tilley, R. D. (2023). Synthesis of hierarchical metal nanostructures with high electrocatalytic surface areas. Science Advances, 9(2), eadf6075. https://doi.org/10.1126/sciadv.adf6075

Liu, C., Hongo, K., Maezono, R., Zhang, J., & Oshima, Y. (2023). Stiffer Bonding of Armchair Edge in Single‐Layer Molybdenum Disulfide Nanoribbons. Advanced Science, 2303477. https://doi.org/10.1002/advs.202303477

Liu, J. (2004). Advanced electron microscopy characterization of nanostructured heterogeneous catalysts. Microscopy and microanalysis, 10(1), 55-76. https://doi.org/10.1017/S1431927604040310

Pawelec, B., & Fierro, J. L. G. Characterization of Catalysts: Bulk and Texture. https://www.eolss.net/ebooklib/sc_cart.aspx?File=E6-190-12-00

Wang, D. (2006). Characterisation of Catalysts by Transmission Electron Microscopy. In Electron Crystallography: Novel Approaches for Structure Determination of Nanosized Materials (pp. 473-487). Springer Netherlands. https://doi.org/10.1007/1-4020-3920-4_30

Zhang, J., Li, M., Kang, Z., Xiao, B., Lin, H., Lu, J., ... & Zhang, Q. (2022). Atomic mechanisms of hexagonal close-packed Ni nanocrystallization revealed by in situ liquid cell transmission electron microscopy. Nano Research, 15(7), 6772-6778. https://doi.org/10.1007/s12274-022-4475-3

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.