When it comes to visualizing structures on the nanoscale, electron microscopy techniques have been revolutionary. With the ability to achieve spatial resolutions on a sub-Angstrom scale and image individual nanoparticles or viruses, electron microscopy has made it possible to spatially map small-scale structures in several dimensions.

Image Credit: WildSnap/Shutterstock.com

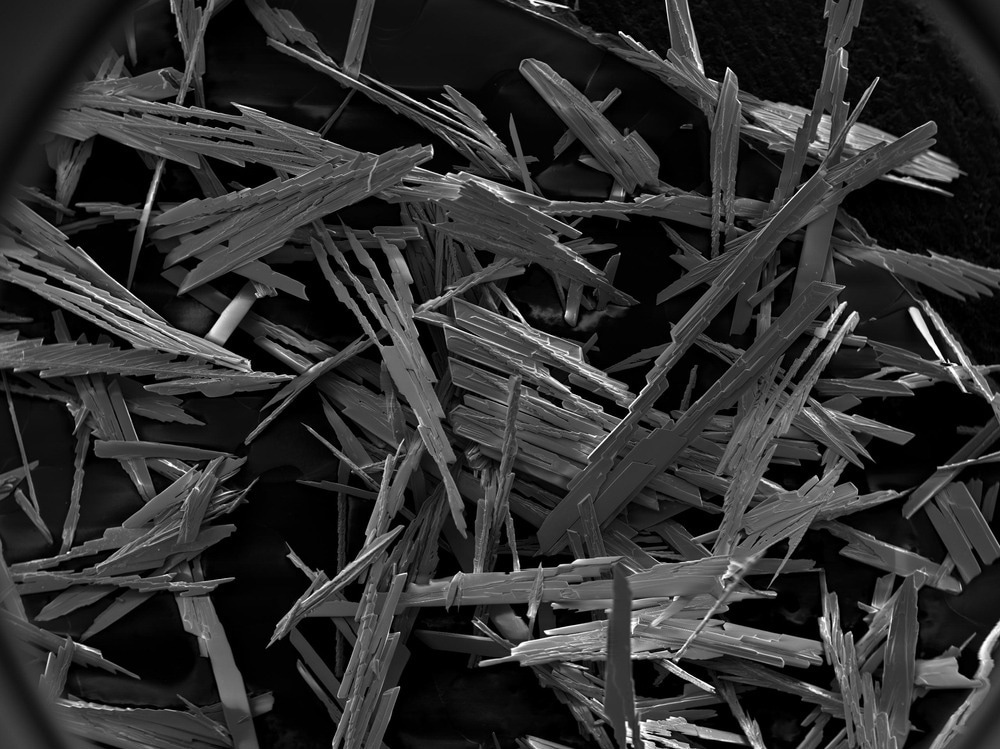

Two of the main electron microscopy methods are scanning electron microscopy and transmission electron microscopy methods. In a scanning electron microscopy measurement, the electron beam is rastered over the sample surface and the secondary electrons emitted by the target are detected. Achieving a high spatial resolution in such experiments is dependent on both the quality and tightness of the focus of the electron beam but also the precision on the raster stages and reproducibility being sufficiently high that the raster movement does not result in ‘blurring’ of the image.

Scanning electron microscopy and transmission electron microscopy can both be used to record ‘flat’ 2D images of a sample, but development in these methods has meant they can be used to provide Z-axis or depth information for a full 3D reconstruction of the sample.3 Recording and the reconstruction of such images is not always trivial, particularly as there are limitations on the probing depth of the electron beams, but with the right sample stage manipulation capabilities and construction methods, a 3D image can be generated.

Now, researchers have been developing 4D electron microscopy methods. Rather than using a continuous electron beam, 4D electron microscopy uses pulsed electron beams to produce temporally short bunches of electrons. By combining this ultrafast electron probe with some sort of short excitation process, typically an ultrafast laser process, it is possible to record 3D electron microscopy images as a function of time – the fourth dimension.

While there are many technical challenges associated with generating ultrashort electron pulses that are still bright enough to record the electron images on a meaningful timescale, 4D electron microscopy, both in scanning and transmission modes, is now being applied to studies of advanced energy materials for batteries.

Battery Analysis

The advantage of applying 4D electron microscopy methods to battery analysis is that they can provide information on the 3D structure, elemental composition, and the temporal evolution of the battery behavior. Researchers have recently applied this methodology to look at how lithium-based rechargeable batteries operate.

The team has been studying lithium iron phosphate materials, which are commonly used as cathodes in rechargeable lithium-ion batteries. In particular, they were focusing on visualizing and capturing how the process of delithiation occurs – how lithium ions leave the cathode.

With the time-resolution provided by the 4D electron microscopy methods, it was possible to track the movement of the lithium ions in real-time. By correlating this process with information on how the local structures in the regions of the cathode near the ion movement, the researchers could identify that partial delithiation generally left core-shell-like structures. While there were a range of different structure types and behaviors, the researchers were able to perform a statistical analysis to conclude that one of the models for to describe linear lattice parameter-composition behavior – Vegard’s Law – was indeed valid for this particular material composition.

With the expense and complexity involved in materials design, having tools like 4D electron microscopy that provide sufficiently comprehensive information at the atomic level is very important for a fundamental understanding of battery chemistry and the verification of proposed models. Knowing how accurate models are and how they can be improved is vital for improving in silico and computational predictive efforts for future materials design.

Structure

Other recent work using 4D electron microscopy for battery analysis has involved studying another lithium-based cathode material, LiNiO2. While LiNiO2 has many appealing properties for applications in battery development, it has proved very difficult to commercialize due to instability issues and the challenges associated in synthesizing the material without defects.

Scientist analyzes nanomaterials in a Transmission Electron Microscope. Image Credit: Rui Serra Maia/Shutterstock.com

Often an important part of materials synthesis and defect formation is the phase transitions that occur during the sample preparation. When materials change phase, through processes such as melting or crystallization, it is possible there are small local changes in the structure that occur known as defects.

Although site-specific and highly localized, defects can introduce a number of changes in the overall material behavior. Sometimes this can be beneficial, such as improving the sample conductivity, and so defects are introduced intentionally, but often it can be detrimental.

Using 4D electron microscopy, the team were able to identify the structural changes associated with LiNiO2 poor stability as a cathode material. By visualizing the specific layered-to-rock-salt transformation phase in real time, and in particular by focusing on the behavior of the nickel atoms, the team were able to identify the particular geometric distribution of the nickel and oxygen that led to such problems.

In future, this time-lapse structural information obtained in the 4D electron microscopy experiments could be used to target areas of the material design to eliminate the instability problems. By finding structural reinforcements around the nickel or different processing approaches that avoid the issues with the observed phase transitions, LiNiO2 could one day become a commercially viable material.

More from AZoOptics: How Do FTIR Gas Analyzers Work?

References and Further Reading

Li, Y., Huang, W., Li, Y., Chiu, W., & Cui, Y. (2020). Opportunities for Cryogenic Electron Microscopy in Materials Science and Nanoscience. ACS Nano, 14(8), 9263–9276. https://doi.org/10.1021/acsnano.0c05020

Stewart, P. L. (2016). Cryo‐electron microscopy and cryo‐electron tomography of nanoparticles.pdf. WIREs Nanomed Nanobiotechnol, 9, e1417. https://doi.org/10.1002/wnan.1417.

Inkson, B. J. (2016). Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) for materials characterization. In Materials Characterization Using Nondestructive Evaluation (NDE) Methods. Elsevier Ltd. https://doi.org/10.1016/B978-0-08-100040-3.00002-X

Flannigan, D. J., & Zewail, A. H. (2012). 4D Electron Microscopy: Principles and Applications. Accounts of Chemical Research, 45(10), 1828–1839. https://doi.org/10.1021/ar3001684

Hughes, L. A., Savitzky, B. H., Deng, H. D., Jin, N. L., Lomeli, E. G., Yu, Y., Shapiro, D. A., Herring, P., Anapolsky, A., Chueh, W. C., Ophus, C., & Minor, A. M. (2022). Correlative analysis of structure and chemistry of Li x FePO 4 platelets using 4D-STEM and X-ray ptychography. Materials Today, 52(February), 102–111. https://doi.org/10.1016/j.mattod.2021.10.031

Ahmed, S., Bianchini, M., Pokle, A., Munde, M. S., Hartmann, P., Brezesinski, T., Beyer, A., Janek, J., & Volz, K. (2020). Visualization of Light Elements using 4D STEM : The Layered-to-Rock Salt Phase Transition in LiNiO 2 Cathode Material. Advanced Energy Materials, 10, 2001026. https://doi.org/10.1002/aenm.202001026

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.