In this interview, AZoOptics speaks to Phaseform, a University of Freiburg spin-off whose approach to adaptive optics is helping to refine optic technologies across applications like life sciences microscopy, ophthalmology, and optical inspection. Here, we discuss the devices that define their innovations, as well as the evolving landscape of adaptive optics.

Please could you introduce yourself and tell us about your role within Phaseform?

My name is Stefan Weber, I have a technical background in photonics, worked for the optical industry, was in the management of two successful start-ups, and I am now leading Phaseform as CEO.

What is the primary mission of Phaseform, and what solutions do you offer?

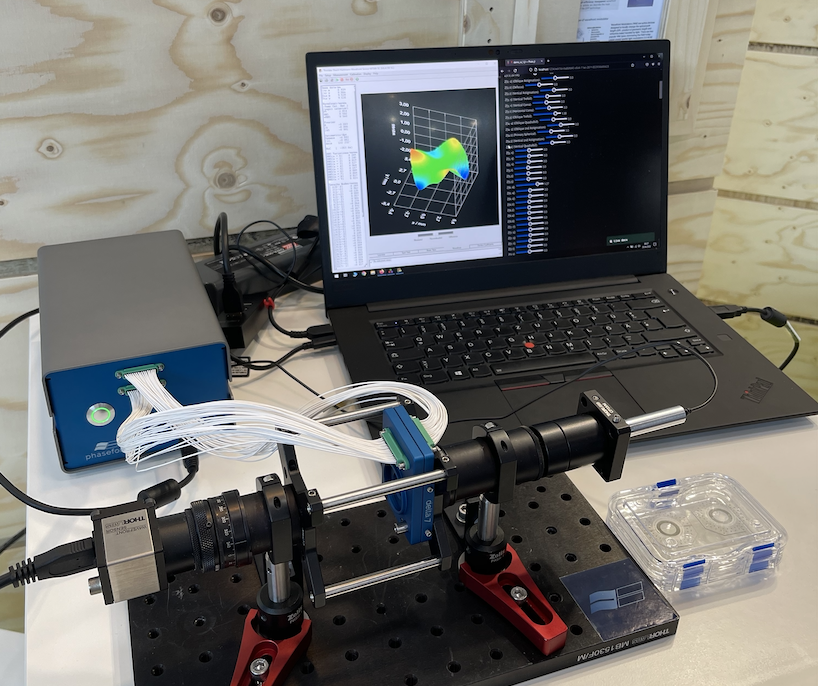

Phaseform offers a new approach to adaptive optics (AO) with transmissive, high-performance components and systems which compensate for wavefront errors of light - thereby improving optical resolution, contrast, and brightness of the recorded images.

What distinguishes Phaseform’s take on adaptive optics compared to others in the sector?

Our technology is fundamentally different from conventional approaches using deformable mirrors (DM) or liquid crystals (LC). First, it is transmissive (refractive) rather than reflective: this makes integrating our devices into existing optical systems much easier because you do not have to fundamentally redesign your optics - it is like adding an additional lens to your system. Second, we have significant advantages in the scalability of our manufacturing, which is a big step towards the goal of universally available high-performance adaptive optics.

The Deformable Phase Plate (DPP) is at the core of Phaseform’s approach to adaptive optics. Could you break down this device?

The DPP is similar to an ordinary tunable (deformable) lens, but with a much higher degree of freedom and control. It can adjust not only focal length, but also correct for astigmatism, coma, spherical aberration - up to optical path differences of the 7th order Zernikes (this is also where the name “Delta 7” comes from).

To achieve this versatility, the Delta 7 has 63 embedded electrodes embedded within the optical aperture, which adjust a flexible membrane surface through electrostatic force - a control method that is both predictable and very precise. As an ultra-thin optofluidic element with a continuous surface, it neither changes the polarization nor introduces diffraction effects.

© 2022 Phaseform GmbH

How does it compare to existing wavefront modulators? What does the Delta 7 based on DPP technology do that cannot be done right now?

Life science microscopy and ophthalmology instruments typically work in refraction, and unlike astronomical telescopes, they are very compact and the cost is a relevant factor. Those are not ideal preconditions for using reflective deformable mirrors or specialized LCs outside fully reflective, high-end systems.

As the world’s highest-performing, continuous-surface transmissive wavefront modulator, we enable novel and more compact optics designs than previously known.

Our linear, hysteresis-free system response is also an important prerequisite for so-called "open-loop operation", allowing us to forgo additional wavefront sensors (“sensorless AO”). In addition, multiple devices can be stacked and controlled "as one" for increased range and fidelity.

How do you see your first products being practically used?

Apart from fundamental research, we see quite an interest from instrument developers for our technology, both from the academic side as well as from the commercial sector. We currently collaborate with innovative firms that push the limits in life science microscopy, ophthalmology and optical inspection.

Are there any other industries that are likely to benefit from adaptive optics technologies?

Adaptive optics, for example, is an important prerequisite for deep-tissue imaging in life science microscopy, or imaging of the human retina with a cellular resolution for diagnostics and non-invasive monitoring of a variety of eye diseases. Optical inspection, in general, struggles with aberrations from non-flat samples and imperfect optics, whereas adaptive optics can be of great benefit as well.

With our scalable technology, we would love to see adaptive optics move out of its current niche - reaching novel industries and benefit an increasing number of researchers, instrument developers and patients - and one day even widespread consumer use, for example, in AR/VR applications.

© 2022 Phaseform GmbH

How do you expect this technology to influence the advancement of the optics sector in the years to come? How do you imagine a future where adaptive optics has become ubiquitous?

With off-the-shelf, high-performance wavefront correction devices on every researcher’s optics table and part of the design of many optical instruments, it will no longer be dependent on perfect system alignment, exclusively high-grade components, the 3D structure of the imaged object, or sample preparation skills to image at the diffraction limit. Nobel laureate Eric Betzig predicts that AO in microscopy will become as widespread as is is already in astronomy, and I expect the same to happen to other fields as well.

Phaseform is a spin-off from the University of Freiburg’s Department of Microsystems Engineering. How did the company handle the transition from the laboratory to the industry? Were there any major challenges you had to overcome?

Luckily, in Germany, there are funding programs specifically tailored to transition great research to great products and great companies. The scheme we obtained is called “EXIST Transfer of Research”. It is a program running since 2007 and supports exceptional science-based startups that engage in high-risk/high-cost research.

Among the success factors of that program are early commitments from the spin-out institute towards the founders in matters of IP-, equipment-, and lab/office use. It also offers workshops to facilitate the necessary mindset change towards exploring the low-hanging-fruits first, and not necessarily the most scientifically fascinating aspects of one’s technology.

One of the major challenges we faced was COVID-19. The global pandemic not only severely curtailed our forward-looking options like canceled events, travel restrictions and otherwise engaged customers, but also from the technical and development side, lab closures and supply chain issues (particularly electronic components). We were indeed lucky again that also, for these difficulties, we could obtain tailored support through the "Start-up BW Pro-Tect" program from the German state of Baden-Württemberg.

Earlier this year, Phaseform exhibited for the first time at the Laser World of Photonics Start-up World pavilion in Munich. How do events like this help to support the growth of startup companies like yourselves?

The Laser World of Photonics exhibition was the first physical event we could attend after the pandemic. We were surprised by the high degree of interest and encouraging feedback we received from both visitors and fellow exhibitors from the Photonics space.

I noticed that handing over our DPP, as an ultra-thin glass plate, to visitors and demonstrating its capabilities live really sparked their imagination as to how they would employ that novel class of optical components in their current and future work.

What has been your most memorable moment during the last years working on that technology?

Actually, that spark I saw in our Laser World visitor’s eyes I experienced as well, in Early 2019, when I first held the first-generation prototype in the Freiburg labs in my hands.

During that time, I was looking for new startup opportunities and took the invitation of my former colleague from EPFL, Çağlar Ataman, to Freiburg so he could show me the latest work of his Ph.D. students at the time, Kaustubh Banerjee and Pouya Rajaeipour. Developing new and working with various AO technologies myself, I immediately recognized the uniqueness and market potential of the technology he just had shown me. Soon after, we formed our team, and successfully submitted the development- and business plan for the ascension to the EXIST program in July 2019, which eventually lead to the foundation of Phaseform.

You recently closed a significant seed investment round. What are your next steps?

We are happy to acknowledge MBG Baden-Württemberg and our private investors for their support and trust. The obtained funds will be used to scale the production of the Delta 7, and invest into the development of our next product based on DPP technology.

About Dr. Stefan Weber

Dr. Stefan Weber is CEO of Phaseform GmbH in Freiburg, Germany. He has a technical background in optics and photonics, and was previously COO of two successful startups in Zurich: SwissLitho AG (now Heidelberg Instruments Nano) which makes rapid prototyping nanolithography tools, and modum.io, selling IoT trackers to the Pharma supply chain. Before that, he was Product Manager at Jenoptik Optical Systems for customers from the semiconductor industry and did his Post-Doc at the EPFL in Neuchâtel and the University of Geneva developing a MEMS-based deformable mirror. He earned his Ph.D. in experimental physics at the FU Berlin, working on polarization-enabled femtosecond pulse shaping techniques using LC spatial light modulators.

Dr. Stefan Weber is CEO of Phaseform GmbH in Freiburg, Germany. He has a technical background in optics and photonics, and was previously COO of two successful startups in Zurich: SwissLitho AG (now Heidelberg Instruments Nano) which makes rapid prototyping nanolithography tools, and modum.io, selling IoT trackers to the Pharma supply chain. Before that, he was Product Manager at Jenoptik Optical Systems for customers from the semiconductor industry and did his Post-Doc at the EPFL in Neuchâtel and the University of Geneva developing a MEMS-based deformable mirror. He earned his Ph.D. in experimental physics at the FU Berlin, working on polarization-enabled femtosecond pulse shaping techniques using LC spatial light modulators.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.