Micrometers are measurement tools for making fine measurements. The most common micrometers have a C-shaped frame with a calibrated screw that can be used to extend or contract a spindle to a known distance. The object to be measured is placed between the frame and spindle and the spindle closed until it is held securely.

Image Credit: Doug McLean/Shutterstock.com

Manual micrometers are easy-to-use and can provide measuring accuracies of ~ 0.01 mm. However, a micrometer screw gauge is not accurate enough for many applications. Instead, for very high accuracy measurements, a laser micrometer can be used.

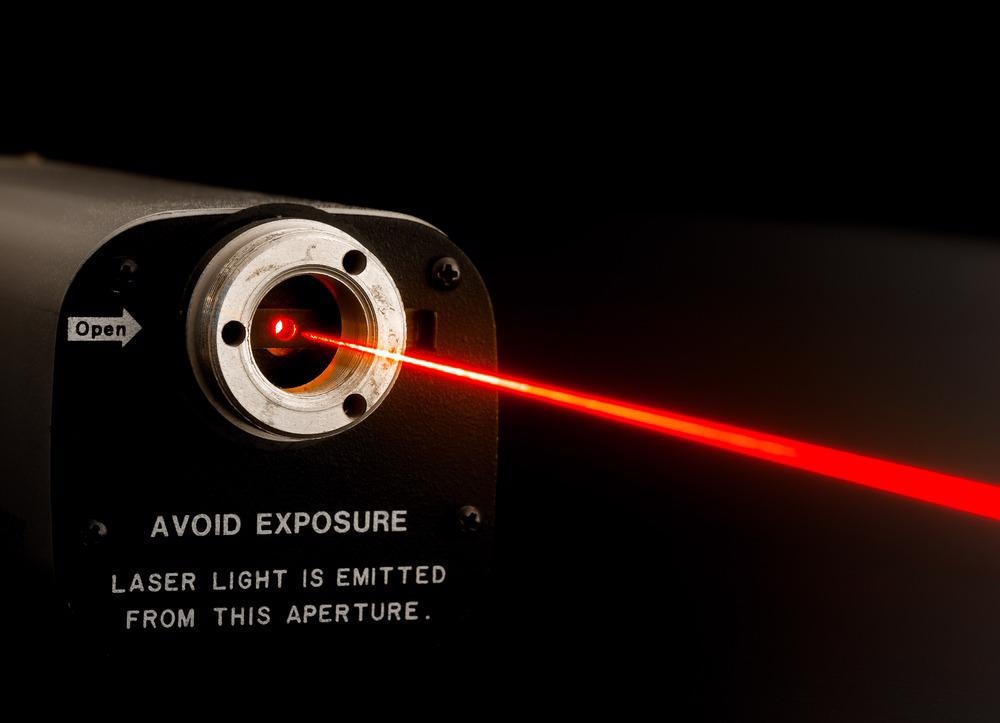

A laser micrometer works by scanning a laser beam between an emitter and a receiver. The laser beam is scanned at a constant speed and any object in the beam will cause a shadow for an amount of time proportional to its size. By counting the amount of time the receiver does not receive light and knowing the scan speed, it is then possible to calculate the object's size.

The advantages of laser scan micrometers are their accuracy, fast scan speeds and relative ease of operation. Laser micrometers can be used for object sizing and as helpful auxiliary tools in measurement – such as measuring the displacement of delay stages more precisely.1

Optical Laser Micrometers

Optical micrometers have a long history, with the first invention being attributed to James Watt in 1770.2 While the principle of using a light source and reflective components and a detector has not changed much, the use of bright, highly collimated laser beams has meant an even greater degree of precision in measurements is achievable.

Accuracies of < 1 µm are now achievable and the miniaturization of LED sources and detectors has also meant that optical micrometers can now even be handheld devices for field measurements.3

The ability to collimate laser beams gives laser-based optical micrometers a significant advantage as it means there is less stray light when the object blocks the beam. Too many stray reflections or diffuse light cause an unwanted background signal and diminish the contrast between when the object is blocking the beam or the light is free to pass through. Poor contrast means a worsening signal-to-noise ratio and potentially longer acquisition times.

New optical schemes are continually being developed for laser micrometers. One significant recent advancement for laser micrometers was the inclusion of an interferometer in the design to help measure two-point cylindrical diameters in one-dimensional displacement interferometry.4

Sub-100 nm reproducible measurements were achievable with this optical scheme which was designed primarily for the measurement of small diameter fibers that can be difficult to achieve with standard 2D laser micrometer measurements.

Applications of Laser Micrometers

One of the key applications of laser micrometers is for non-contact testing. The ability to perform two-dimensional and higher scans with laser micrometers means they can be used to reconstruct an object in multiple dimensions.5 The ability to rapidly scan objects without interrupting any industrial processing means on-the-fly feedback systems can be implemented for advanced process control.

The high spatial resolution of laser micrometer measurements makes them ideal for complex manufacturing tasks that demand a high degree of precision. With an increasing demand for micro-electromechanical systems (MEMS) and other nanofabrication manufacturing techniques, laser micrometers are becoming increasingly important for the control and diagnostics of manufacturing machines.6

While many lithography techniques now have an excellent spatial resolution in terms of the size of the ion beams, the manufacturing accuracy and precision that can be achieved are still dependent on the rastering process for the sample stage. Many scanning microscopy applications are also dependent on highly accurate translations of the sample holder.

Advancements in Laser Micrometers

2D laser micrometers are now being integrated with more complex robotics to make advanced measurement systems capable of looking at material properties such as the height and pitch of threads.7 For applications with small tolerance ranges, the continually improving accuracy of laser micrometers is highly appealing as well as the ability to measure objects with more complex shapes. Traditionally, such measurements would have to have been performed offline using microscopy techniques such as optical microscopy.

Improved source and detector capabilities are also important for continuing the development of laser micrometers. For the ‘Industrial Revolution 4.0’ in manufacturing, where there is a push to greater degrees of automated manufacture, online detection and analysis become critical.

For true process control with laser micrometers, scan speeds need to be very rapid. Where higher accuracies and precisions are desirable, the demands on the laser collimation and spot size also increase, with even small aberrations leading to problematic behavior and inaccuracies. However, laser micrometers are already a widely used tool and their ability to perform non-contact measurements means they are likely to remain so as the new age of automation continues.

References and Further Reading

- Zolotoyabko, E., & Quintana, J. P. (2002). Time and phase control of x-rays in stroboscopic diffraction experiments. Review of Scientific Instruments, 73, 1643–1645. https://doi.org/10.1063/1.1425386

- Jones, R. V. (1976). The Optical Micrometer. Optical Engineering, 15(3), 247–250. https://doi.org/10.1117/12.7971959

- Del’Oro Management (2015) Optical Micrometer, https://www.expometals.net/en-gb/news-page-aeroel-srl/measuring-wires-and-cables-with-the-worlds-first-really-contactless-portable-optical-micrometer-id10672, accessed May 2022

- Stoup, J., & Doiron, T. (2021). A novel high accuracy micrometer for the measurement of diameter. Metrologia, 58, 025002. https://iopscience.iop.org/article/10.1088/1681-7575/abd3b2

- Valino, G., Wdowik, R., Misiura, J., & Zapico, P. (2017). Non-contact measurement of grinding pins laser micrometer laser micrometer. Procedia Manufacturing, 13, 534–541. https://doi.org/10.1016/j.promfg.2017.09.080

- Büttner, H., Michael, K., Gysel, J., Gugger, P., Saurenmann, S., Bortoli, G. De, Stirnimann, J., & Wegener, K. (2020). Innovative micro-tool manufacturing using ultra-short pulse laser ablation. Journal of Materials Processing Tech., 285(March), 116766. https://doi.org/10.1016/j.jmatprotec.2020.116766

- Lavrinov, D.S., Pokazanev, S.V. (2022). The Analysis of the Measurement System Accuracy Based on 2D Laser Optical Micrometer When Measuring API Pipe Thread Pitch and Height. In: Radionov, A.A., Gasiyarov, V.R. (eds) Proceedings of the 7th International Conference on Industrial Engineering (ICIE 2021). ICIE 2021. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-85230-6_25

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.