The Diffusil® range of optical diffusers offers a combination of almost-perfect diffusion characteristics with a robust housing able to resist even the most challenging operating conditions.

This article explores some of the most frequently encountered challenges of optical diffusion, highlighting how Diffusil® optical diffusers can overcome these challenges to provide high performance in exacting applications.

Ideal Optical Diffuser Properties

The term ‘optical diffuser’ can be used to describe any instrument that considerably reduces the spatial coherence of light. An optical diffuser essentially spreads out light in a disordered manner, blurring - or preferably removing - bright or dark spots to ensure a more uniform output.1

An optical diffuser should ideally demonstrate Lambertian reflectance,2 meaning that it would exhibit similar behavior to a perfectly ‘matte’ surface.

For example, if a tightly-focused laser beam was directed towards a Lambertian (reflective) diffuser, any reflected light would spread evenly in every direction. Measuring the intensity of reflected light in any direction would provide no indication of the laser beam’s original angle.

An optical diffuser’s performance requirements vary greatly depending on its use and application.

For example, a sheet of white paper would likely suffice for a commercial photography application, but engineering and research applications, such as sensing, spectroscopy or photovoltaics, require the use of an optical diffuser which approximates a perfect Lambertian.3

Diffusil® optical diffusers offer industry-leading quality, an almost-perfect Lambertian response to incident radiation and can accommodate wavelengths in the 190 nm to 3200 nm range.

These diffusers are also extremely robust, leading to their application in a wide range of highly demanding settings.

Most notably, Diffusil® is approved for interplanetary use, resulting in optical calibration targets made from Diffusil®-UV material being installed on the SHERLOC spectroscopy device fitted on NASA’s Perseverance Mars rover. Diffusil® calibration targets also see routine use in various satellites.

Challenges in Optical Diffuser Design

Many diffusers utilize materials with highly random structures. These materials will scatter light in all directions, though this is often a deliberate design decision. While optical diffusers have been developed using a range of approaches, all of these share some common challenges.

Impurities

Insufficient material purity will limit the quality of an optical diffuser, also limiting a manufacturer’s capacity to accurately specify its performance. Impurities may reduce the diffuser’s overall transmittance or reflectance, as well as directly impact diffusion.

Inhomogeneity

Inhomogeneity is a common issue in optical diffusers which utilize bubble-filled materials like glass. Inhomogeneous size distributions and bubble patterns may cause inconsistency in finished products and reproducibility issues.

OH Absorption

Most routinely used optical diffuser materials include hydroxyl groups that strongly absorb in the infrared region. This absorption can significantly limit their effectiveness in applications requiring transparency to infrared.

Fragility

Optical components which are not robust can only realistically be used in laboratory environments and are frequently unsuitable for industrial or engineering uses.

Diffusil® Optical Diffusers: Ideal for High-spec Applications

Diffusil® diffusers offer advanced optical characteristics and unmatched durability, even in the most extreme environments – characteristics which allow them to overcome the limitations of other diffuser materials.

Uniform Scattering Properties

Diffusil® material includes an ultra-homogenous distribution of approximately 4 μm diameter gas bubbles within 99.999% pure fused silica.

Their near-perfect spherical shape and strictly controlled distribution allow these bubbles to function as optimal scattering centers, affording the material an exceptionally uniform structure with extremely Lambertian scattering properties.

Diffusil® diffusers are suitable for use in reflection (Diffusil-R) or transmission (Diffusil-T) mode. Their opacity can be tailored to meet customer requirements thanks to the versatile sol-gel manufacturing process.

Hydroxyl-free

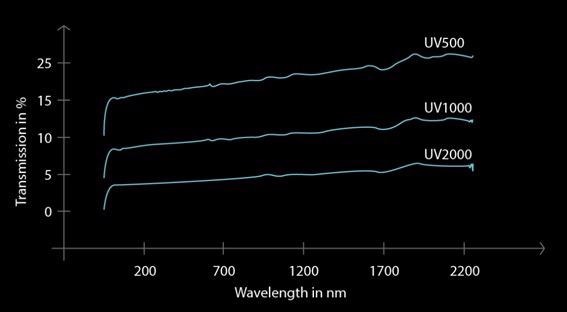

Diffusil®-UV materials contain no OH groups or water, unlike other diffusers, including other fused silica devices. This vital quality means that accuracy is assured throughout the full UV-VIS-NIR spectrum.

Image Credit: Firebird Optics

Extreme Durability

Firebird’s Diffusil®-UV optical diffusers exhibit improved resistance to challenging environments, outperforming glass, PTFE and even other fused silica products in this regard.

They can withstand strong acids and bases, temperatures up to 1000 °C, and thermal shocks of several hundred degrees without sustaining damage - a key factor in their suitability for applications in extreme environments.

Throughout their efforts to evaluate optical diffuser materials destined for use in satellite applications, researchers at the Metrology Research Institute and National Physical Laboratory determined that Diffusil® offers better resistance to UV degradation and contamination when compared to a range of other popular diffuser materials.4

Firebird Optics – The Optimal Partner for Optics

Firebird Optics offers a comprehensive range of optical components beyond optical diffusers. These include beam splitters, lenses and optical windows. The company is also able to offer an array of customized optical components designed to meet customer specifications.

References

- Paschotta, D. R. Diffusers. https://www.rp-photonics.com/diffusers.html.

- Fairchild, M. D. Color Appearance Models. (John Wiley & Sons, 2005).

- Rahimzadegan, A. et al. Towards Perfect Optical Diffusers: Dielectric Huygens’ Metasurfaces with Critical Positional Disorder. Advanced Materials n/a, 2105868.

- Vaskuri, A., Greenwell, C., Hessey, I., Tompkins, J. & Woolliams, E. Contamination and UV ageing of diffuser targets used in satellite inflight and ground reference test site calibrations. 972, 012001 (2018).

This information has been sourced, reviewed and adapted from materials provided by Firebird Optics.

For more information on this source, please visit Firebird Optics.