UpNano, an Austrian company specialized in high-precision optical 3D printing, has developed two additive manufacturing materials suitable for use with its two-photon polymerization 3D printing technology.

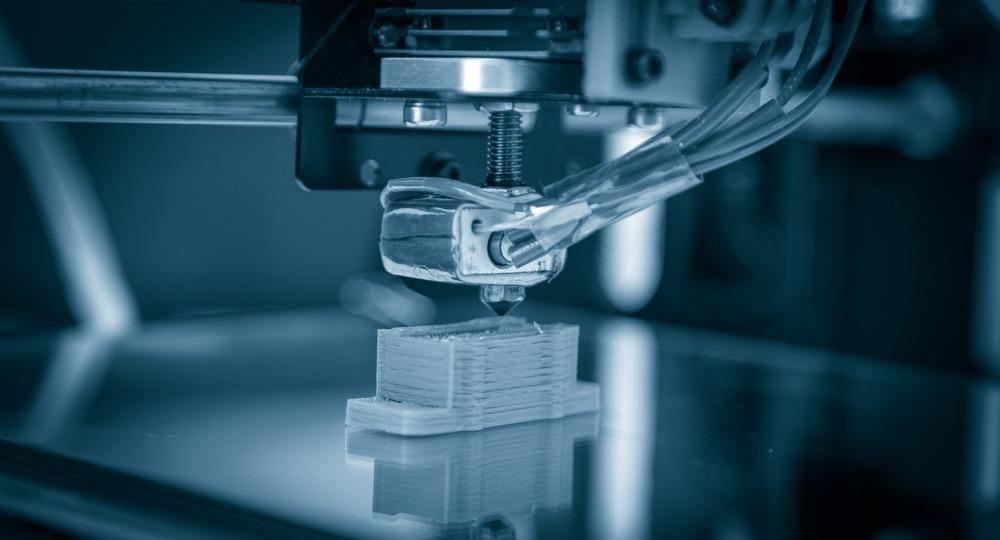

Image Credit: Alex_Traksel/Shutterstock.com

The novel photopolymer materials branded UpBlack and UpOpto permit the printing of non-transparent and optically translucent components, respectively, that can be integrated into 3D-printed optical systems.

Additive manufacturing has dramatically improved the flexibility and quality of component fabrication in several industrial sectors, including automotive, electronics, aerospace, and bioengineering. Complex optical devices and systems can similarly benefit from the ability of advanced 3D printing techniques to create low-cost structures and high-precision of nearly arbitrary shapes.

Additive Manufacturing Improves Production Efficiency

Traditionally, optical components are conventionally by milling, grinding, and polishing pre-fabricated polymer or glass moldings. Such components usually have to be fabricated with simple geometries and in large quantities to ensure cost-effective manufacturing. In many research and industrial sectors, however, individual custom-made optical components, such as corrective eyeglass lenses, adaptive optical elements, and other freeform optics, are becoming increasingly important.

The cost-effective integration of multiple functionalities into optical components is nearly impossible with conventional manufacturing techniques. To address that challenge, novel additive manufacturing technologies and materials are currently being developed.

Cutting-Edge Optical 3D Printing Techniques Achieve Sub-Micron Resolution

In comparison to the conventional manufacturing technologies, where the material is removed, the 3D printing process relies on material deposition to create the desired shape.

3D printing is based on the layer-by-layer deposition of material according to a digital model of the component to be printed. The model is divided into virtual slices that are transferred sequentially to the 3D printer, which builds the component one layer at a time.

A variety of 3D printing methods are being developed, where the individual layer thickness is of the order of 100 µm, which are highly suitable for mechanical manufacturing applications and enable the implementation of a wide variety of novel designs and functionalities.

In terms of optical applications, most of these methods result in structurally inhomogeneous components with comparatively poor surface quality.

In the last decade, several optical 3D printing technologies, based on light-induced polymerization of photo-sensitive materials, attract increasing attention from the industry. In particular, the two-photon polymerization (2PP) method demonstrated the ability to achieve spatial resolution down to 100 nm or less.

Recently, UpNano, a high-precision 3D-printing specialist company based in Vienna, Austria, has unveiled two photosensitive polymers developed for use with the company's proprietary 2PP 3D printing technology.

Two-Photon Polymerization Methods for Next-Generation 3D Printing Optical Systems

The basis of the two-photon polymerization is a non-linear optical process, where a focused laser pulse is absorbed by the photosensitive material with an extremely high spatial selectivity, thus resulting in material polymerization only in the focal plane of the laser beam. This enables continuous fabrication of high-precision structures with a sub-wavelength accuracy directly within the material volume, without repetitive material application.

Until recently, the 2PP technology was regarded as a relatively slow and time-consuming additive manufacturing process, mainly suitable for microscale fabrication.

Since its foundation in 2018, as a spin-out of TU Wien (Technische Universität Wien), UpNano has developed NanoOne, which, according to the company, is the fastest high-resolution 3D printing system on the market. The system combines a high-power femtosecond laser (1W maximum output) with high-resolution optics and an ultra-high-speed galvanometer scanner for unprecedented writing speeds of up to 1500 mm/s and a total printing volume of 120 mm x 100 mm x 50 mm.

In parallel with the innovative 3d printing optical system, UpNano's team has developed a range of photopolymerizable resin formulations optimized to utilize the full potential of the high throughput of the NanoOne 3D printing system.

High-Power Lasers for 3D Printing of Light-Absorbing Materials

Among the latest additions to the company's portfolio are UpBlack and UpOpto, photopolymerizable materials that enable the printing of non-transparent and optically transparent components, respectively.

The company states that the two complementary materials can be used together to create entire optical systems, including components such as lenses, lens holders, and beam stops, in a single manufacturing step.

Despite the relatively high light absorption of UpBlack, the high laser power of NanoOne delivers sufficient energy for rapid and complete polymerization of the liquid photopolymer during manufacturing, resulting in non-transparent parts printed with sub-micron accuracy.

3D Printing of Integrated Optical Systems

On the other hand, UpOpto is an optically clear material that exhibits very low fluorescence, which is particularly beneficial when manufacturing components for optical, biological, and medical applications.

UpOpto also exhibits very good biocompatibility and certified non-cytotoxicity, which makes the photopolymer a material of choice for the biomedical and microfluidics markets.

UpNano's team envisages that the two novel materials, together with the advanced NanoOne optical 3D printing system, can be used for the rapid manufacturing of integrated optical systems, where non-transparent structural elements are seamlessly combined with transparent high-precision optical components with a surface roughness of less than 10 nm, designed to address a wide range of customer-specific applications.

References and Further Reading

UpNano (2021) Novel Material Allows 2PP 3D Printing of Non-Transmissive (Black) Structures [Online] www.upnano.at Available at: https://www.upnano.at/novel-material-allows-2pp-3d-printing-of-non-transmissive-black-structures

K. Sertoglu (2021) UpNano launches new 3D printing materials for high-precision optical systems [Online] www.3dprintingindustry.com Available at: https://3dprintingindustry.com/news/upnano-launches-new-3d-printing-materials-for-high-precision-optical-systems-197723

Bunea, A.-I., et al. (2021) Micro 3D Printing by Two-Photon Polymerization: Configurations and Parameters for the Nanoscribe System. Micro, 1, 164-180. https://doi.org/10.3390/micro1020013

H. Everett (2020) UpNano uses high power laser to speed up two-photon 3D printing process [Online] www.3dprintingindustry.com Available at: https://3dprintingindustry.com/news/upnano-uses-high-power-laser-to-speed-up-two-photon-3d-printing-process-175679

Bagheri, A., Jin, J. (2019) Photopolymerization in 3D Printing. ACS Appl. Polym. Mater. 1, 4, 593–611. https://doi.org/10.1021/acsapm.8b00165

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.