Non-destructive testing (NDT) methods are used for the research and testing of materials. Several types of NDT are used for this purpose, including ultrasonic testing, visual testing, and magnetic particle testing. One particularly useful NDT method is using X-ray tomography. Now, a team at HZB has presented an X-ray tomography method that achieves unprecedented speeds.

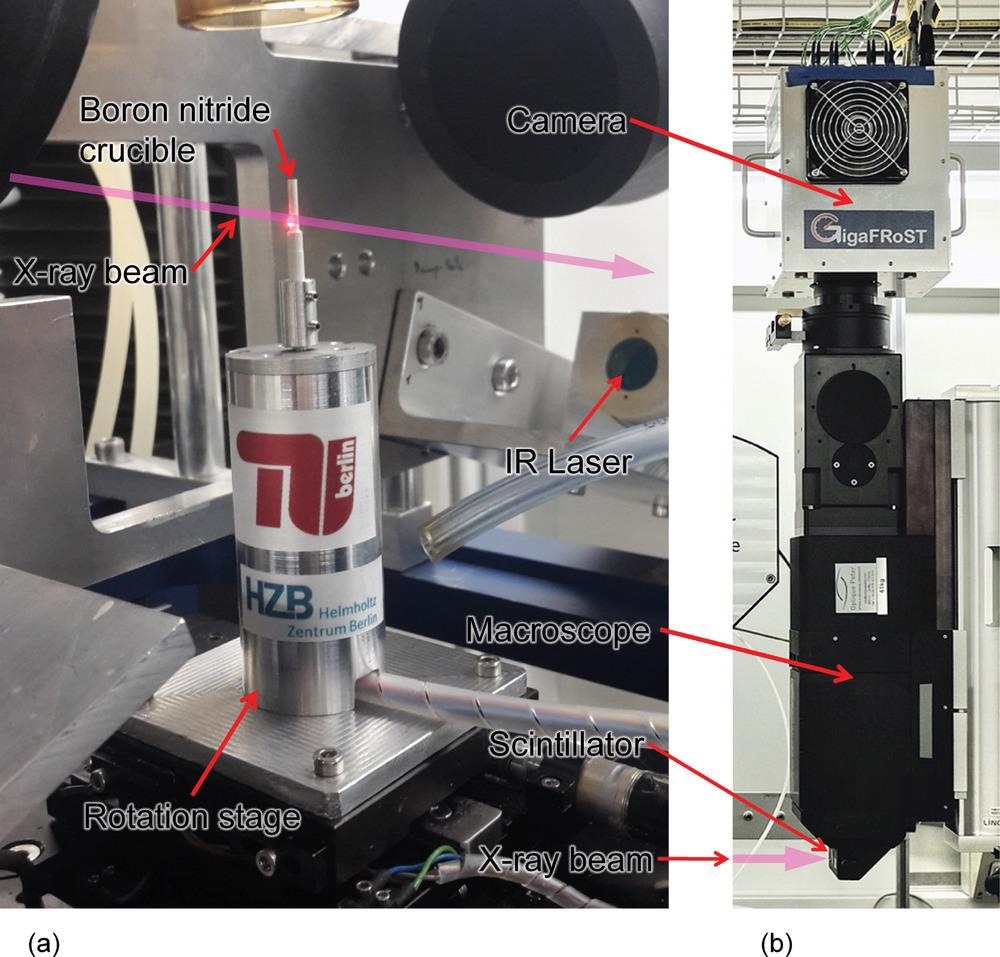

Tomoscopy setup installed at the TOMCAT instrument of the SLS, PSI comprising: a) A self-developed high-speed rotation stage (operational up to 500 Hz, i.e., allowing for up to 1000 tps) and a hollow cylindrical boron nitride crucible into which the samples are inserted. Heating of the samples is provided by two 150 W IR lasers placed in perpendicular to the X-ray beam illustrated by a pink arrow here. b) Position of the LuAG:Ce scintillator screen, the optical macroscope, and the GigaFRoST CMOS camera on top. Image Credit: Garcia-Moreno, F et al.

What is X-Ray Tomography?

The most known use of X-ray tomography is in medicine. Computed tomography (CT or CAT) is used to scan a patient’s body in three dimensions. Sectional images produced by the scan are then used in disease diagnosis. However, a lesser-known use of the method is for analyzing materials. Additionally, it is used for non-destructive testing and in the development of new materials.

X-rays pass through matter, losing energy as they do so (this is governed by the law of Beer). This property makes them ideal for materials analysis. However, to be able to analyze materials with high spatial resolution in the least amount of time, a strong X-ray source is necessary. The best radiation source for this purpose is a synchrotron. If a sample can be imaged in three dimensions quickly enough, even rapid changes and processes that occur in the material can be analyzed.

The method has been enhanced by advanced machine learning tools, image acquisition with real-time reconstruction algorithms, feature segmentation, and advanced image analysis. Powerful laboratory scanners with improved spatial and temporal resolution are widespread.

Accelerating the Speed of Tomography

The HZB team, in collaboration with colleagues from the Paul Scherrer Institute (PSI) in Switzerland, is working on this problem.

The team managed to reach 200 tomograms per second, with a method they termed fast imaging tomography. Now, they have reached speeds of 1000 tomograms per second, a new record in tomography. At this speed, it is possible to image processes in the material or even during manufacturing, which is not possible with current methods of X-Ray tomography.

There is no major compromise in other parameters, even at these high speeds.

Spatial resolution is possible on the micrometer scale and experiments can be carried out over the space of several minutes without interruption. This ultra-high-speed and resolution variation of tomography has been termed “tomoscopy.” Thus, a new frontier in non-destructive testing has been reached.

The Equipment

To produce the images, the team had to develop new equipment in-house. A high-speed rotary table was used to house the sample. The angular speed of the table can be synchronized perfectly with the acquisition speed of the camera. Lightweight components were used in the rotary table to reach 500 Hertz rotation speeds.

The team used a high-speed camera with specially designed optics at the TOMCAT beamline at the Swiss Light Source at the PSI. The SLS specializes in time-resolved X-Ray imaging. This setup significantly increased the sensitivity, allowing for 40 2D projections to be taken in one millisecond.

With the planned SLS 2.0 upgrade, it will be possible to take even faster measurements with vastly improved spatial resolution from 2025.

Processing the Data

A huge data stream was generated by the project. Initially, this was stored at the PSI and 1000 three-dimensional data sets were generated over the span of several minutes.

Further processing and evaluation of the data was the responsibility of Dr. Paul Kamm at HZB. Reconstructing the raw data into three-dimensional images was carried out remotely from HZB, with the results transferred to HZB for further analysis.

Demonstrating the Power of Tomography

Several examples were used to demonstrate the power of the technique. Images were produced which showed the rapid changes as a sprinkler burned, coalescing bubbles in a liquid metal foam, and dendrites forming as casting alloys solidified. To put the importance of one of the images produced into perspective, metal foams based on aluminum alloys have potential application in electric cars as lightweight materials. Analysis of cross-linking, size, and morphology of the bubbles are important to achieve the desired mechanical properties of the material for large components.

High-Performance X-Ray Sources: Making Tomography Possible

When the technique becomes widely available for researchers worldwide, achieving the high speeds necessary for tomography will require a commercially available high-quality X-Ray source. The L9181-02 from Hamamatsu is a microfocus X-Ray source that is fit for purpose.

Features include high power (a maximum 39 W output) a focal spot size of 5 µm (sharp and clear images are possible even at high magnification) an integrated high-voltage power supply, and external control via its RS232C interface. Applications for the L9181-02 are non-destructive inspection and X-Ray CT.

The Future of Tomoscopy

With the L9181-02 and other high-quality, commercially available equipment on the market already, tomoscopy is set to make an entry into the toolkit of material scientists and companies in the next few years.

The research undertaken by the team at HZB and PSI will provide faster, better resolved, and more dynamic non-destructive testing for the materials science sector, as well as potentially in other disciplines.

References and Further Reading

Garcia-Moreno, F et al. (2021) Tomoscopy: Time-Resolved Tomography for Dynamic Processes in Materials Advanced Materials [Accessed 14th October 2021] https://onlinelibrary.wiley.com/doi/full/10.1002/adma.202104659

Phys.org (Website) New world record in materials research: X-ray microscopy at a speed of 1000 tomograms per second [Accessed online 14th October 2021] https://phys.org/news/2021-09-world-materials-x-ray-microscopy-tomograms.html

Hamamastsu (Website) L9181-02 Microfocus X-ray source [Accessed online 14th October 2021] https://www.hamamatsu.com/eu/en/product/type/L9181-02/index.html

Intechopen.com (Website) The Use of Computed Tomography to Explore the Microstructure of Materials in Civil Engineering: From Rocks to Concrete [Accessed online 14th October 2021] https://www.intechopen.com/chapters/55976

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.