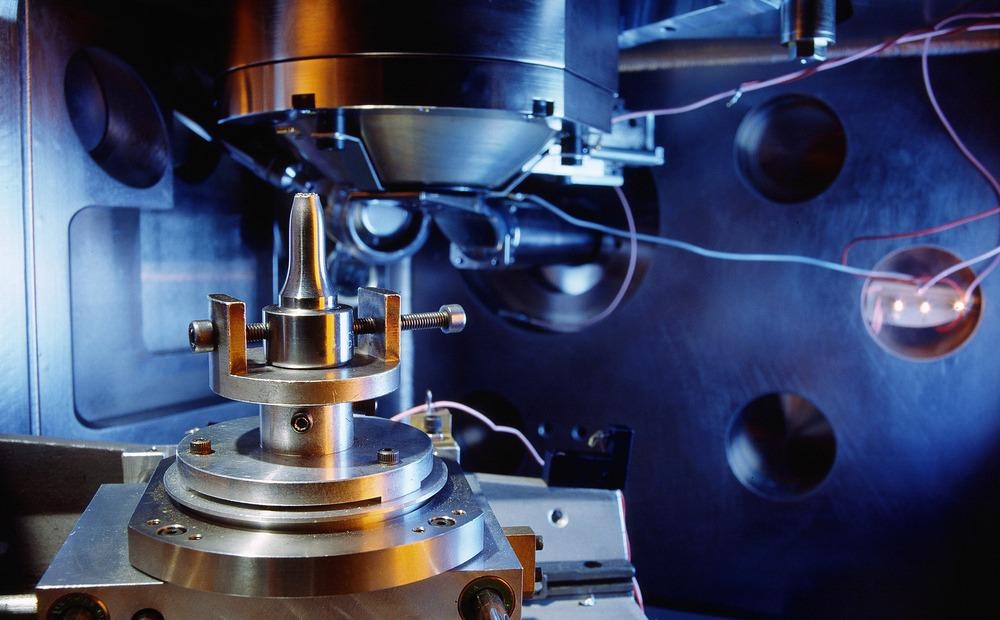

Originally developed in 1933 by German electrical engineer Ernst Ruska, the electron microscope is an advancement of the optical (light) microscope, with the capability to achieve far greater resolutions to allow for detailed images. The electron microscope has been developed since it was established in the 1930s. Since this time, scientists have successfully used electron microscopes in a wide range of scientific fields to study a variety of samples, including cells, microorganisms, large molecules, biopsies, crystals, and metals. They are a well-established piece of equipment in biology and are also commonly used to examine materials to carry out quality control and failure analysis.

Image Credit: Bildagentur Zoonar GmbH/Shutterstock.com

What is Electron Microscopy?

The electron microscope utilizes a beam of accelerated electrons to illuminate a sample. Electron wavelengths are around 100,000 times shorter than those of the photons of visible light and it is this shortened wavelength that gives the electron microscope its higher resolution.

Since the development of the electron microscope, scientists have created variations of the technology. Perhaps the most widely used in the study of materials is the scanning electron microscope (SEM).

SEMs use a beam of fast-moving electrons in the same way that regular electron microscopes do to shine through a sample, however, instead of lenses, they use coil-shaped electromagnets to generate a magnification by bending the electron beams that pass through. Images produced by SEMs are of a higher resolution than those created by electron microscopes, allowing scientists to view the composition, morphology, and topography of a sample in greater detail.

Electron and scanning electron microscopes have been widely adopted in materials science due to the advantage they provide of being able to examine and understand materials at the level of the particle. Scientists can use this information to develop enhanced materials with properties that are better suited to their purpose. Here, we discuss how electron microscopes are benefiting the study of materials.

The Use of Electron Microscopy in Materials Science

Because electron microscopes and SEMs produce images at high resolutions, they have been widely adopted by materials science, most commonly for quality control tests. Visualizing materials at high resolutions allows scientists to identify faults that may lead to the material failing its purpose. These sorts of predictions are essential for ensuring the safety of various products and structures. The fields of aerospace, electronics, chemistry, and energy all use electron microscopes and SEMs to test materials.

Measuring Nanoparticles

Electron microscopy is important for the development of new materials. Nanoparticles have become a keen area of interest for the development of many applications. Their unique properties attributed to their tiny size are only just being understood and exploited by scientists.

To develop materials with the enhancement of nanoparticles, scientists must first characterize different nanoparticles to understand their properties and how they interact with other compounds to determine their potential uses.

Electron microscopy is being used to explore nanoparticles to help develop their use in creating new and enhanced construction materials. The below products have all benefited from the addition of nanoparticles which election microscopy has helped to define and understand

- Anti-graffiti nanocoatings

- Anti-reflection nanocoatings

- Electrochromic and photochromic nanocoatings

- Photocatalytic nanocoatings

- Self-cleaning nanocoatings

- Smart window nanocoatings

- Super-hydrophilic and hydrophobic nanocoatings

- UV-protection nanocoatings

Electron microscopy has helped to explore how nanoparticles can be used to develop new materials to help clean up environmental contaminants.

Developing Carbon Nanotubes for Medical Applications

An area in which electron microscopy is currently helped to study and develop new materials in is the field of medical applications. Specifically, election microscopy is helping scientists to develop the use of carbon nanotubes in biomedical applications. Materials used for such purposes require specific properties.

The surface roughness of materials used in biomedical applications has a significant impact on their functionality. Numerous research projects have used various versions of electron microscopy to help determine the surface roughness of materials to understand the optimal properties.

Studies have recently used electron microscopy to investigate the surface roughness of carbon nanotubes to understand how to manipulate carbon nanotubes in various biomedical applications. Studies with electron microscopy have revealed intricate details about the optimal preparation of carbon nanotubes, including how velocity, advancement, and cutting depth impact the surface roughness and therefore the properties of carbon nanotubes.

Electron Microscopy in the Future of Materials Science

Electron microscopy will likely continue to play a vital role in the study of materials. The development of biomedical applications, in particular, may benefit from studies using this tool. The high resolution of electron microscopy lends it to materials science and will continue to assist scientists in understanding the properties of materials, with the study of nanoparticles at the forefront of this area of research.

References and Further Reading

Caputo, F., Clogston, J., Calzolai, L., Rösslein, M. and Prina-Mello, A., 2019. Measuring particle size distribution of nanoparticle enabled medicinal products, the joint view of EUNCL and NCI-NCL. A step by step approach combining orthogonal measurements with increasing complexity. Journal of Controlled Release, 299, pp.31-43. https://www.sciencedirect.com/science/article/pii/S0168365919301130

Courtland, R., 2018. The microscope revolution that’s sweeping through materials science. Nature, 563(7732), pp.462-464. https://www.nature.com/articles/d41586-018-07448-0

Sato, H., O-Hori, M. and Nakayama, K., 1982. Surface Roughness Measurement by Scanning Electron Microscope. CIRP Annals, 31(1), pp.457-462. https://www.sciencedirect.com/science/article/abs/pii/S0007850607633472

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.