Image Credit: Bildagentur Zoonar GmbH/Shutterstock.com

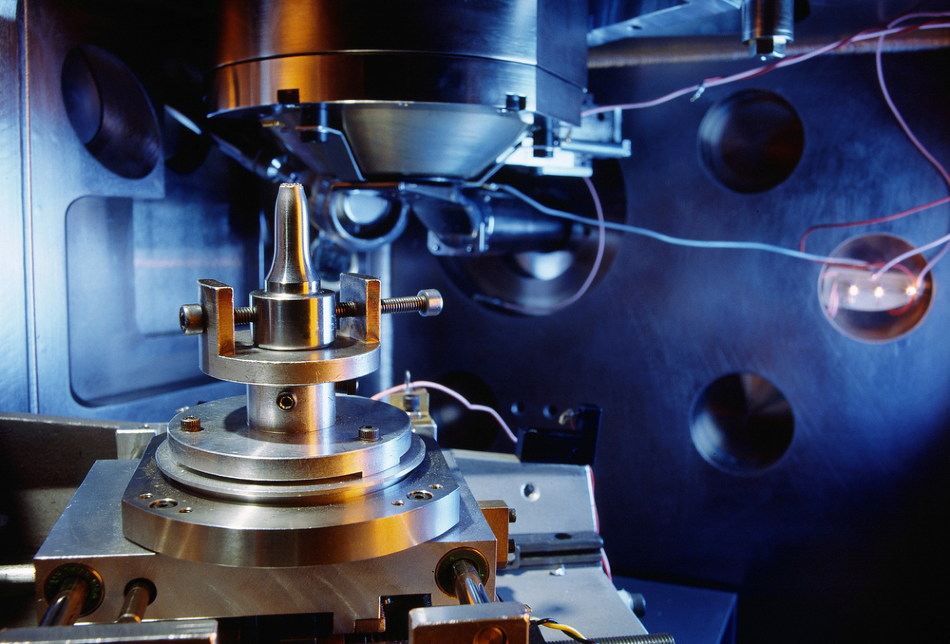

Friction and wear are common tribological interactions that are brought about when two solid surfaces are brought together without adequate lubrication—often in scenarios where there has previously been enough lubrication, but the lubricant has since degraded. Given that wear and friction can happen in many industrial and mechanical environments, many methods are dedicated to analyzing friction, wear and the subsequent degradation of mechanical parts that these mechanisms cause.

In this article, we’re going to look at how electron microscopy and spectroscopy can be used in the analysis of friction and wear.

Friction between two surfaces that are not well-lubricated is one of the main reasons for machinery failure, which in turn leads to increases in down-time and cost. This is undesirable for many of the sectors that utilize such mechanical systems. Many of the techniques in use today will either analyze the lubricant (to see if it needs changing) or analyze the surface of the mechanical parts to see the extent of the damage.

However, there is another way these systems can be analyzed. The interaction of the surfaces―be it in a chemical, thermal or mechanical manner—leads to the formation of a tribological film (also known as a tribofilm) and this attaches to the worn surfaces. This then contributes to the differing amounts of friction and wear behavior, so it is an important aspect to analyze that can often be overlooked in favor of the other aspects mentioned above.

Given the nature of these films, more specialist techniques are required to probe them, and this is where electron microscopy and spectroscopy techniques have found a use for analyzing tribological systems and providing information on the degree of friction and wear in the system.

Electron Microscopy and its Use in Analyzing Tribofilms

Scanning Electron Microscopy (SEM)

SEM is the most widely used microscopy technique to analyze tribofilms and uses the backscattering of electrons which hit the film to analyze it. When the electrons are backscattered from the tribofilm, they are collected by sensors and the analysis can then be performed or further analyzed by spectroscopy components attached to the SEM (as mentioned below).

SEM is widely used to image tribofilms because it can be used to determine the morphology of the surface, including the 3D morphology. This enables the SEM to determine whether the components have experienced any wear (due to excess friction), whether there are any rough surfaces that are susceptible to further degradation, as well as seeing if there are any fractures on the surface of the metal components.

SEM can also be used to not only determine the wear, but it can also provide more information about the tribological system by measuring the intensity of the backscattered electrons. This can enable the SEM to also measure the local chemical composition of the tribological system as well areas of localized heavy elements and light elements.

The backscattering of electrons can also be used to detect cracks, the presence of oxides (for determining the degree of oxidation), and metallurgical defects such as the degree of porosity and non-metallic inclusions.

Transmission Electron Microscopy (TEM)

TEM is similar to SEM but the electrons during the analysis transmit through the tribofilm rather than being backscattered by it. TEM can be used in several different imaging modes to provide information on the microstructural features of a tribological system, including grain boundaries, crystalline defects, and fine precipitates, as well as smaller features such as the ordered atomic stacking, dislocations and stacking faults, and short-range ordered domains.

Spectroscopy

While there are many spectroscopy techniques that are stand-alone, the ones used to investigate tribofilms are often coupled with the electron microscopes so that more information can be probed simultaneously. This is particularly useful in commercial applications where time equals money and costs are to be reduced if possible.

The spectroscopy analyses often utilize energy dispersive X-ray (EDX) spectroscopy—which are commonly coupled to SEM microscopes (as is the case for EDX in other applications)―and energy electron loss spectroscopy (EELS), which is usually coupled with TEM.

Overall, the microscopy methods are used to identify the specific friction and wear features, whereas the spectroscopy methods are used to quantify the chemical makeup of the tribological environments under analysis.

EDX spectroscopy is used in conjunction with SEM because it is an accurate technique, but it is often used for analyzing the lighter elements present within the mechanical system. Despite this, it can be used to analyze tribo-oxidation films and provides a 2D map of the chemical composition present in and around the areas of friction and wear.

EDX spectroscopy can also be used to characterize microstructural changes in the wear regions at varying degrees of depth, including deformation, cracking, delamination, transferred layer and intermixing.

EELS is made possible with TEM through the inclusion of a prism that transforms the transmission into a spectrum that can be analyzed. It can analyze a wider range of elements than EDX and can be used, alongside determining elemental compositions in the tribological environment, to identify elemental stochiometric ratios, bond transitions, molecular edges, and can provide a 2D distribution of elements in a certain environment.

References and Further Reading

“Electron Microscopy and Spectroscopy in the Analysis of Friction and Wear Mechanisms”- Luo Q., Lubricants, 2018, DOI: 10.3390/lubricants6030058

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.