AZoOptics sat down with AMS Technologies at the LASER World of PHOTONICS 2019 show in Munich, Germany, to discuss their laser solutions and the applications they are involved in.

Can you tell us a bit about AMS Technologies and why you are exhibiting at LASER World of PHOTONICS 2019?

For 35 years, AMS Technologies has primarily been known as a distributor; focusing on optical and power technology, and thermal management. However, several years ago, we expanded our focus from distribution to providing solutions as well.

Right from the beginning, we have developed our business by using components and elements from our suppliers, arranging them into systems that solve our customers' problems. Now, we also provide solutions that we engineer ourselves.

These solutions mainly center around the optical and thermal domains, and we've now started to branch out into the power industry. That is how AMS has evolved over the last few years, and now our focus is very much on communicating the part of the business that offers solutions.

LASER World of PHOTONICS is our most important show because lasers and fiber technology, as well as other optical technologies, are a major part of our solutions portfolio.

Are you attending any other shows this year?

We were at Photonics West, but mostly because we have a lot of suppliers from the U.S, and we like to meet and greet them. As far as customers are concerned, the U.S. is not a market for us.

Of course, if anybody from the U.S wanted to buy from us, we would not say no! But on the distribution side, the contracts we have with suppliers mainly focus on Europe. Therefore, the majority of our shows are in Europe, and LASER World of PHOTONICS is our biggest one for this year.

You are showcasing a new development kit for compact water coolers - please could you tell us about it?

The mRC-KIT-900-TWIN is a very compact development kit. The unique thing about it is that it has two independent chillers in one box - so you have two separate cooling circuits, which can be kept at two different, very stable temperature points.

Some customers want their lasers held at a certain temperature to achieve a specific goal, and so they have to be very precisely regulated and controlled. This is always a challenge because lasers are usually switched on and off, and therefore, the heat load goes up and down very fast. For this mode of operation it takes a lot of effort to make sure the temperature does not change too much.

This is where our development kit can come in. The temperature maintenance is carried out by specialized, compact compressors that can be controlled across a broad range. They can react very quickly to a changing heat load.

The compactness of the kit is partly due to the small tanks that are used in the water loops. In standard water cooling systems, pumps are used to circulate the water. If the pressure on the suction side gets too low, cavitation - a build-up of air bubbles - occurs and the pumps are destroyed. To avoid that, you usually have to have a high water column, meaning a big tank.

The trick here is to pressurize the water system using an electric air pump, which can be controlled automatically. This way we can use very small tanks and still avoid cavitation. Another advantage of the electric air pump is that you can empty and refill the complete water loop very easily. You can press the water out or suck it in, which makes it easier to maintain.

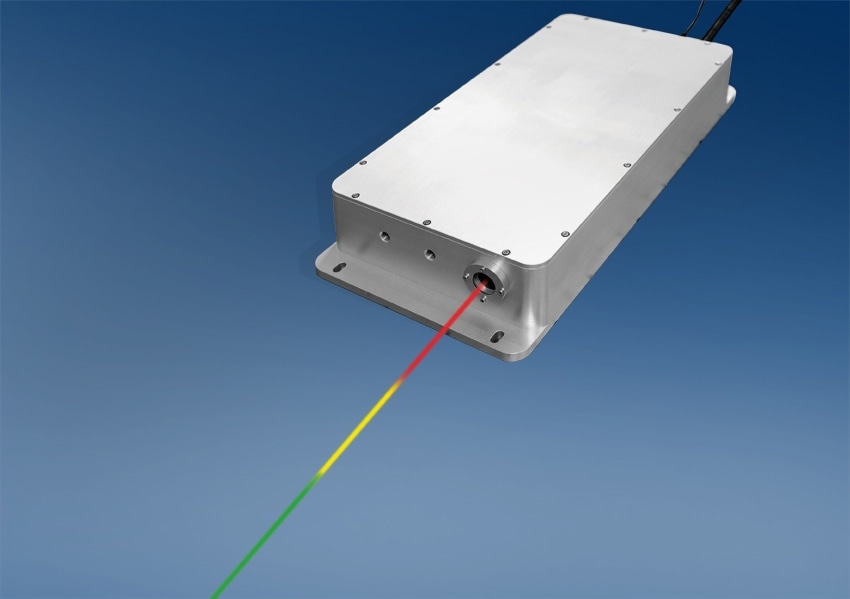

You are also showcasing the TETRA laser today. Could you tell us a bit about that?

This laser can switch between four output wavelengths very rapidly. The main application for this technology is multispectral photoacoustic imaging.

Until today, Optical Parametric Oscillators (OPOs) were used to switch between wavelengths. With an OPO, you can generally reach switching frequencies of around 200Hz at a maximum. Our TETRA laser can reach 2kHz.

In photoacoustic imaging, the laser beam is used to shoot pulses at a sample; for instance, human tissue. When the laser beam hits the tissue, the light is absorbed, and from the absorption, the tissue heats up and expands. This expansion emits an ultrasound wavefront.

You can detect the ultrasound wavefront that is emitted, and by the strength of the ultrasound signal, you can work out the rate of absorption - which is specific for certain cell types or substances.

Usually, you perform the procedure with one pulse wavelength and then detect the ultrasound response. For some applications, it is better, or provides you with additional information, if you change the wavelength because then the absorption of the sample is tested at several specific wavelengths.

For example, a customer who tries to detect skin cancer in an early stage needs to see if the blood cells that run through the skin are oxygen saturated or not. To detect saturated oxygen and non-saturated oxygen, you have to use different wavelengths. The advantage of using our solution is that each area you are looking at can be examined with four wavelengths in one scan.

Previously, researchers had to scan the area, switch the wavelength, and then scan again. When you come back, the blood has probably traveled somewhere else in the body, so it is better if you do it quasi-instantaneously.

What application areas do AMS Technologies cover on the whole?

It would be quicker to say the application areas that we don't cover! We have so many products, and we sell in so many different markets, for various applications.

For example, we have installed a fiber bundle in The Louvre in Paris, but then we have also created a cooling solution for livestock transport of pigs. There can be some extraordinary applications!

What sets AMS Technologies apart from their competitors?

What sets us apart is our technology set, and the fact that we can offer customized solutions, engineered at our company and based on the technological know-how we have in-house, as well as with our suppliers.

Most of our colleagues in development and sales have a very technical education. Many of them have PhDs, meaning they understand the technology and the specific needs of our customers. We are not a standard distributor where you buy and resell standard products - we go into much more detail.

If people are looking for a standard product, they can get it from us. But it's not primarily what we are about. We love technical challenges. We love to go for topics that everybody else is reluctant to discuss, and we invest a lot of time into these areas. We are not afraid of long term projects. We take the challenge, and this makes us unique.

About Caspar Grote

Caspar Grote has been a technical writer, responsible for content at AMS Technologies, since 2017. He compiles the company's very diverse technical solutions, services and products into the company's online and print publications. Caspar Grote is also responsible for press relations at AMS Technologies.

After his education as an electronics engineer and several years as a design engineer in the electronics industry, Caspar Grote worked from 1995 to 2017 in various roles as a specialist editor, editor-in-chief and organiser of specialist conferences, seminars and workshops for a large German specialist media house.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.